Preparation method of composite material used as lithium-sulfur battery cathode material

A technology for positive electrode materials and lithium-sulfur batteries, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low utilization rate of positive electrode active materials and poor cycle stability of lithium-sulfur batteries, and achieve low price and easy operation. The effect of convenience and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Stripping of montmorillonite: Prepare 1mM montmorillonite solution, add 15mM sulfuric acid, and stir for 5h.

[0028] (2) Polymer monomer intercalation and sulfur dispersion: Add 20mM acrylonitrile monomer to the acidified montmorillonite solution, and disperse for 5 hours at a speed of 100r / min. According to the total mass of montmorillonite and polyacrylonitrile: Add elemental sulfur at a ratio of 1:1, ultrasonically disperse for 30 minutes, and then use a high-speed mixer to stir for 1 hour, so that the purity of 99% sulfur element with a particle size of 5 μm is uniformly dispersed in the mixed solution.

[0029] (3) Polymerization coating: slowly drop 30mM sodium persulfate into the mixed solution, and the dropping time is controlled at 10min. The molar ratio of sodium persulfate to acrylonitrile monomer is 1:1.

[0030] (4) Re-aggregation of layered inorganic compounds: Add potassium hydroxide with a concentration of 0.5M to the mixed solution, and the droppi...

Embodiment 2

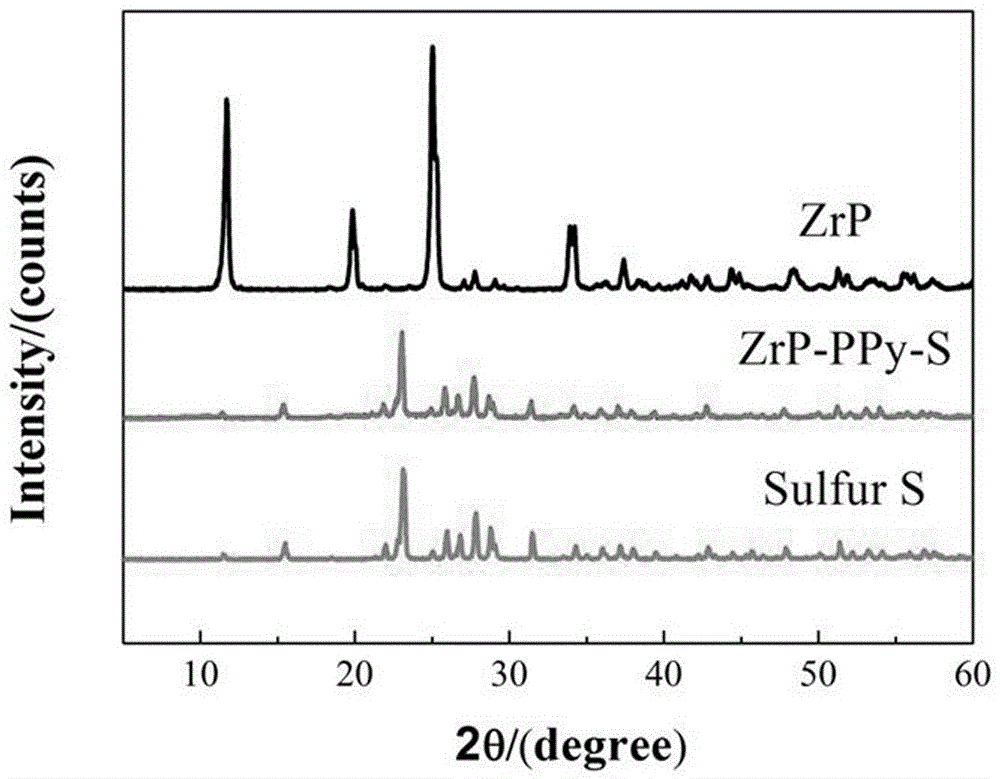

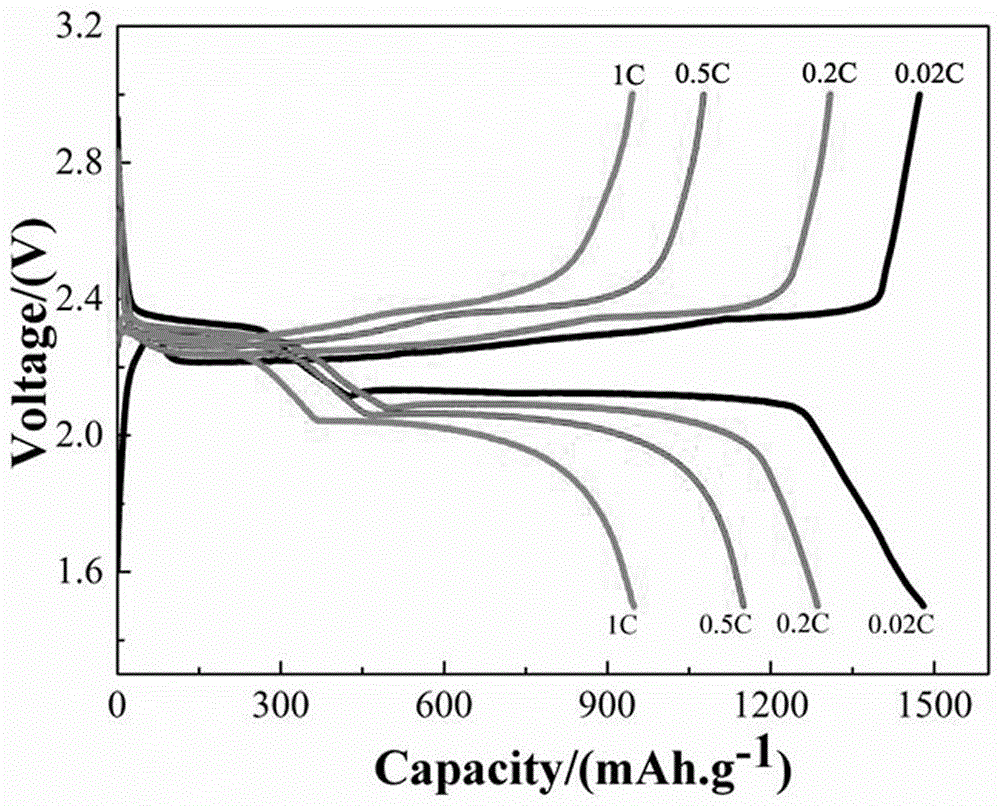

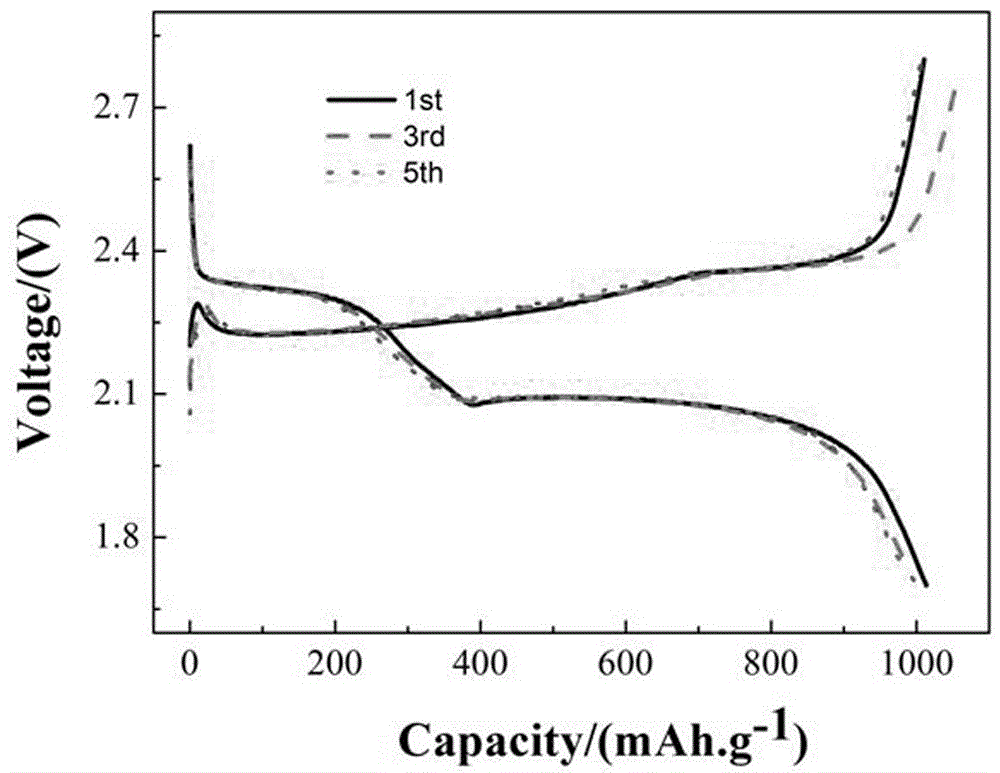

[0032] (1) Exfoliation of layered inorganic compounds: Prepare 15 mM zirconium phosphate aqueous solution, add intercalation agent 20 mM tetrabutylammonium hydroxide, stir for 6 hours, and form a transparent colloidal solution after the exfoliation is completed.

[0033] (2) Polymer monomer intercalation and sulfur dispersion: Add 20mM pyrrole monomer to the solution after peeling, and disperse for 4 hours at a speed of 800r / min. According to the total mass of zirconium phosphate and polypyrrole: sulfur element = 4: Add elemental sulfur at a ratio of 6, ultrasonically disperse for 40 minutes, and then use a high-speed mixer to stir for 4 hours, so that the purity of 99% sulfur element with a particle size of 3 μm is evenly dispersed in the mixed solution.

[0034] (3) Polymerization coating: slowly drop 30mM ferric chloride into the mixed solution, and the dropping time is controlled at 120 min. The molar ratio of ferric chloride to pyrrole monomer is 2:1.

[0035] (4) Re-agg...

Embodiment 3

[0040] (1) Stripping of layered inorganic compounds: Prepare 5mM tin phosphate aqueous solution, add intercalation agent 10mM tetrabutylammonium hydroxide, stir for 12h, and form a transparent colloidal solution after stripping.

[0041] (2) Polymer monomer intercalation and sulfur dispersion: Add 10mM pyrrole monomer to the solution after peeling, and disperse for 1 hour at a speed of 2000r / min. According to the total mass of tin phosphate and polypyrrole: sulfur element = 3: Add elemental sulfur at a ratio of 7, ultrasonically disperse for 60 minutes, and then use a high-speed mixer to stir for 4 hours, so that the purity of 99% sulfur element with a particle size of 3 μm is evenly dispersed in the mixed solution.

[0042] (3) Polymerization coating: slowly drop 15mM ferric chloride into the mixed solution, and the dropping time is controlled at 80 min. The molar ratio of ferric chloride to pyrrole monomer is 1.5:1.

[0043] (4) Re-agglomeration of layered inorganic compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com