High polymer material and metal composite material, and preparation process therefor

A technology of polymer materials and composite materials, which is applied in the field of composite materials, can solve problems such as misjudgment and key switch function failure, and achieve the effects of preventing impact, good electrical conductivity, and offsetting thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Formula A: the mixing rubber (SE4705U of Dow Corning Company for selection) 100 (parts by weight, the same below) containing the methyl vinyl silicone rubber of fumed white carbon black, simethicone oil (XiameterPMX-200 for selection of Dow Corning Company, 1000cs ) 50, vinyl tri-tert-butylperoxysilane (VTPS) 1, dicumyl peroxide (DCP) 0.5.

[0030] Formulation B: SE 4705U 100, VTPS 1, DCP 0.5.

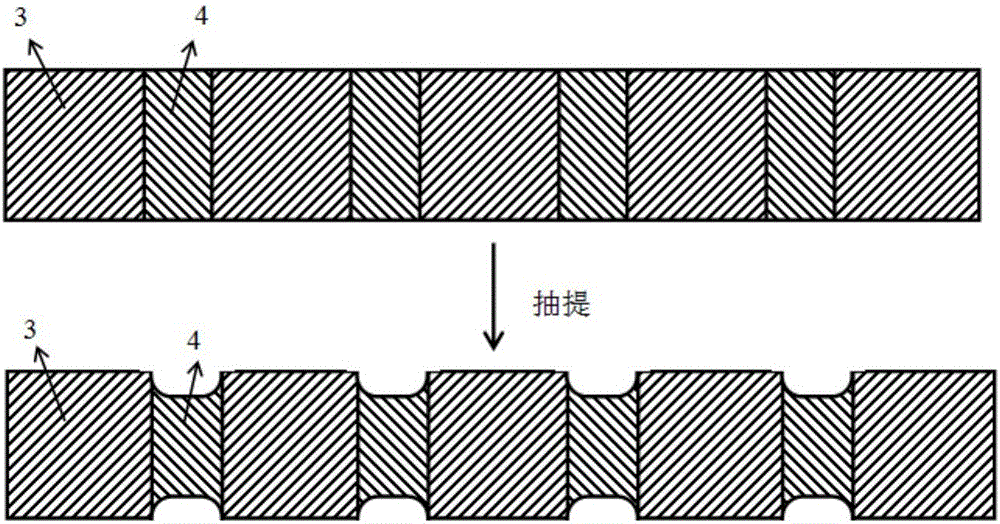

[0031] Lay the mixed films of formula A and formula B respectively with a nickel expanded mesh (the purity of nickel is not less than 99.5%) with a thickness of 0.25mm, a hole diameter of 0.5mm, and a hole spacing of 0.25mm, and put them on a Teflon-coated In the mold cavity of the layer, under the temperature condition of 175° C., press and vulcanize for 10 minutes to form a thin sheet with a thickness of 0.25 mm. This sheet was die cut into small discs with a diameter of 3.0 mm. Using ethanol as a solvent, the small discs prepared by formula A and formula B were extracted wi...

Embodiment 2

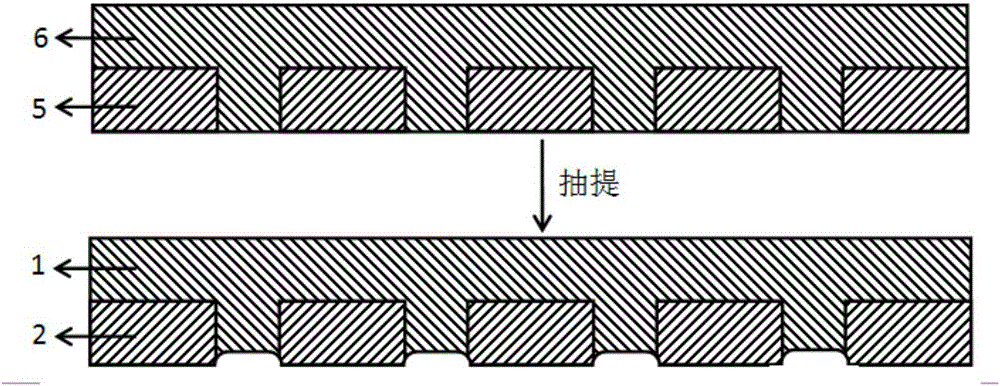

[0034] One side of the nickel expanded metal in Example 1 is pasted with a 0.025mm thick polyimide (PI) self-adhesive film, then compounded with the compounded glue of formula A and the nickel expanded metal to make a 0.8mm thick composite sheet material. The PI self-adhesive film was removed, and punched into small discs with a diameter of 2.0-5.0 mm. Soak in solvent gasoline to extract the silicone oil contained in the small disc silicone rubber, and the rubber in the holes of the nickel plate mesh shrinks ( image 3 ).

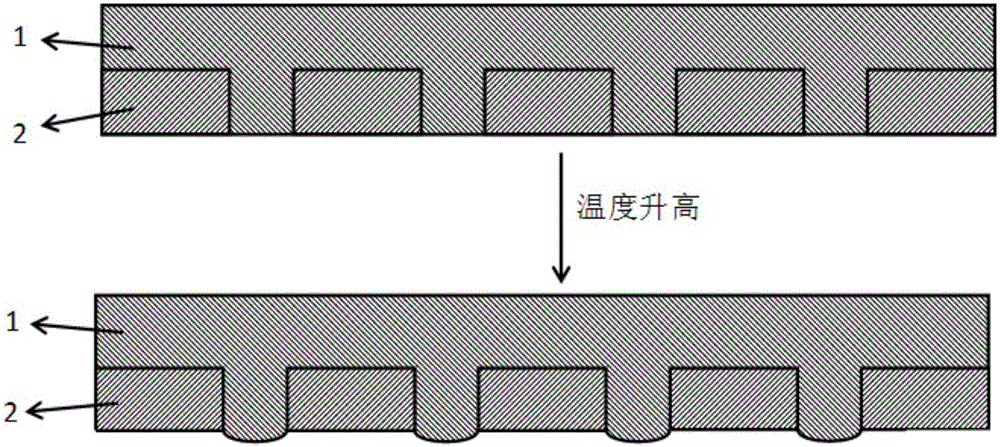

[0035] These small discs serve as electrical contacts and are also capable of conducting electricity well at elevated ambient temperatures. This is because when the temperature rises, such as from 25°C to 80°C, even if the rubber in the porous metal hole has a low expansion coefficient, it will not protrude from the surface of the porous metal (such as Figure 4 shown).

Embodiment 3

[0037] Formula C: PVC (P=500) 100, ethylene-vinyl acetate-carbon monoxide copolymer (select Elvaloy 741 of DuPont Company) 45, dioctyltin dilaurate 2, epoxy soybean oil 3.5, polyethylene wax 0.3, monostearin Glyceride 3, trioctyl trimellitate 65, polyvinyl butyral (molecular weight 20000) 5. The addition of polyvinyl butyral is to improve the adhesion of PVC to metal.

[0038] According to formula C, put all the materials into a high-speed mixer for mixing and stirring. The time is controlled at about 15 minutes, and the temperature is 110-120°C. Let the PVC powder absorb the plasticizer without stickiness. Put it into a low-speed cooling mixer while stirring. Cooling; when cooling to about 25°C, release the material. This material is applied to a multi-layer stainless steel sintered net made of 5 layers of 80-mesh AISI 304 stainless steel plain weave net through special lamination pressing and vacuum sintering processes, or it is plasticized at 160 °C by a double-roll mill. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com