Method for starting once-through boiler with boiler circulating pump when boiler circulating pump breaks down

A boiler water circulating pump and once-through furnace technology, which is applied to boiler cleaning control devices, control systems, steam generation, etc., can solve problems such as starting methods that cannot be used to solve problems, and achieve the effect of recovering economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

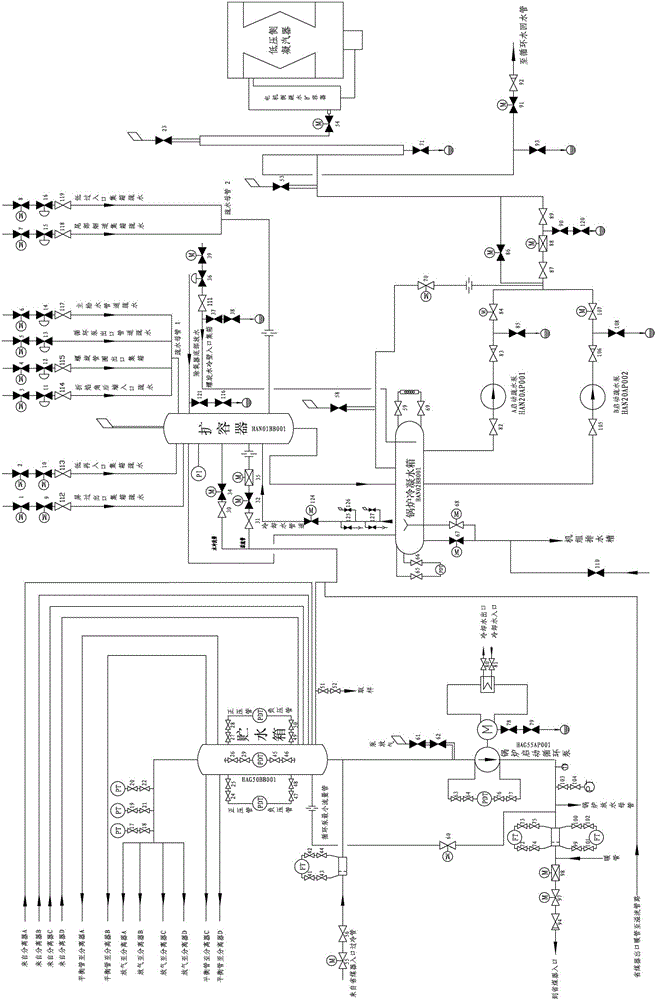

[0024] like figure 1 As shown, the conditions that should be met in the early stage are as follows:

[0025] 1. The system of this method adopts a built-in starting system with a recirculation pump; the system is simple and reliable, easy to operate, small in steam temperature disturbance, and conducive to the safe operation of the steam turbine; Recover the hydrophobic energy of the separator; according to the design requirements of the boiler performance, when the load is above 30% MCR, the bypass system will be decoupled and the separator will be in dry operation. At this time, the separator will only function as a steam circulation header and the system will be started Designed according to full pressure;

[0026] The starting system consists of the following equipment and pipelines:

[0027] (1) Start the separator and the inlet and outlet connecting pipes;

[0028] (2) Water storage tank;

[0029] (3) Overflow pipe and overflow valve;

[0030] (4) Hydrophobic expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com