Weaving topical finishing big-package non-powered automatic shifting device

A traverse device and post-finishing technology, which is applied in the direction of textiles, textiles, papermaking, looms, etc., can solve problems such as high labor intensity, unstable effect, and poor machine synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

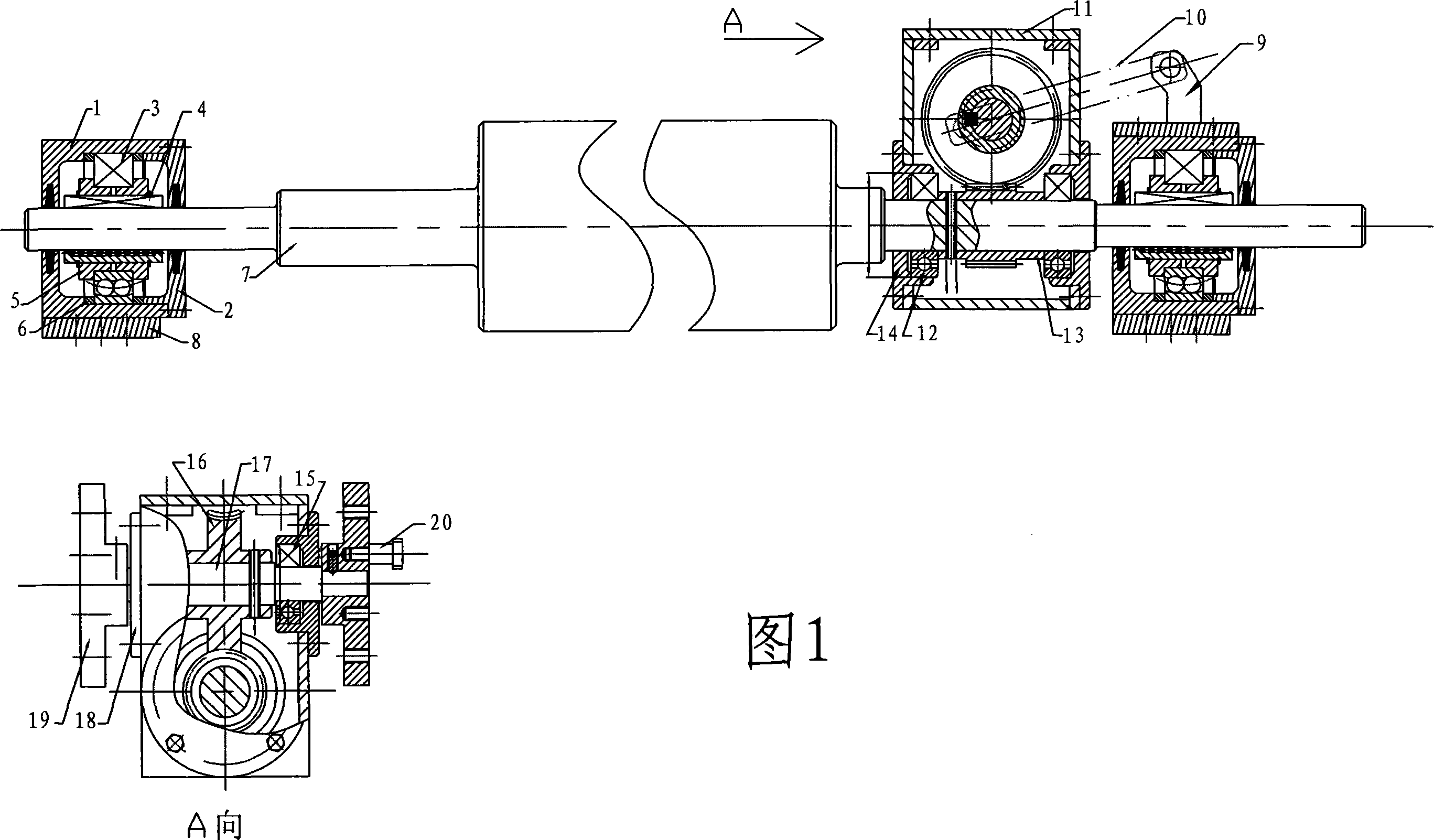

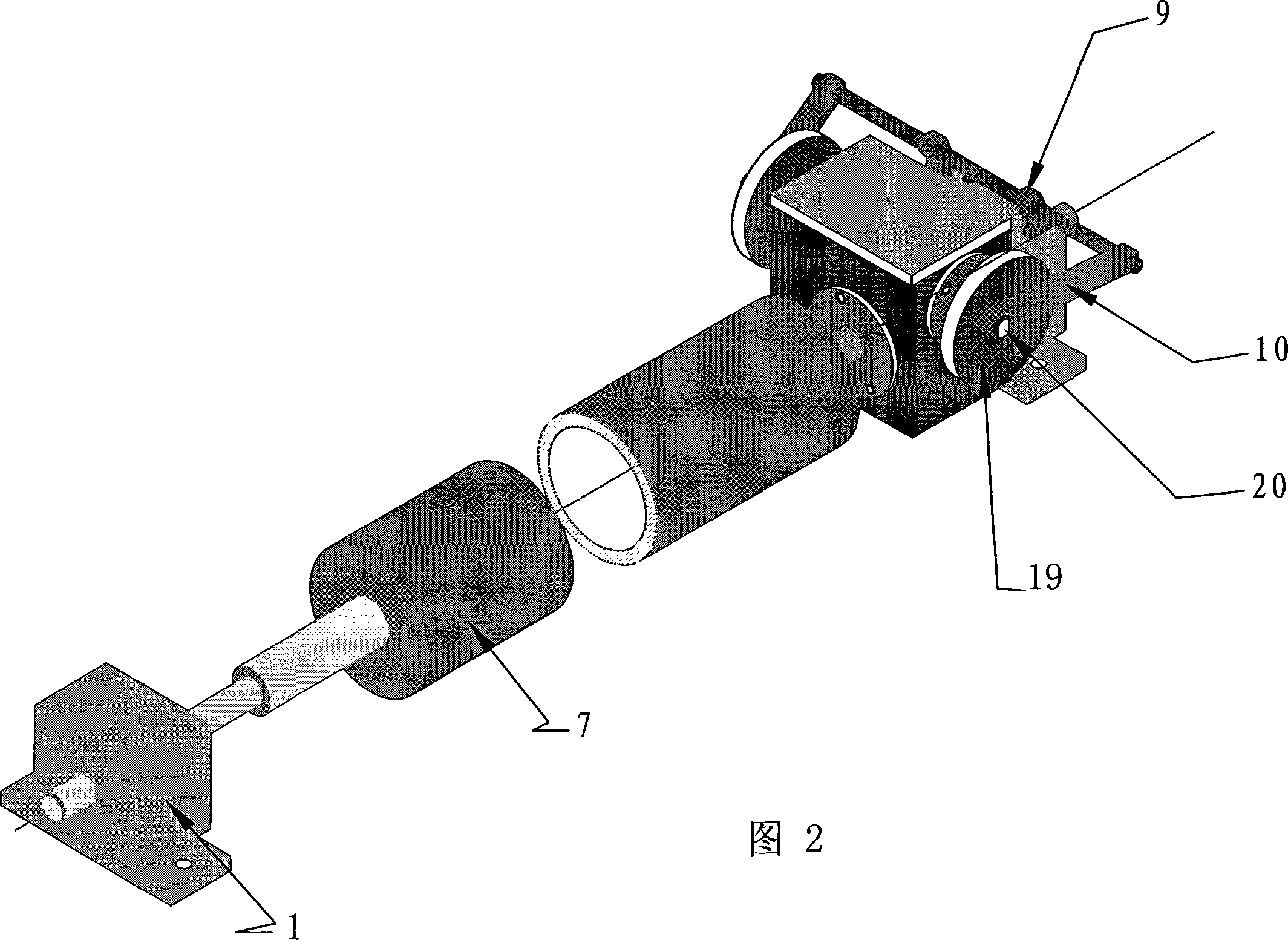

[0023] After the above structure is determined, the main parameters of each main component are determined. First, determine the parameters of the traverse roller (the diameter of the cloth part is 125 mm, the length is 1800 mm, and the total length is 2400 mm); then according to the diameter of the cloth part of the traverse roller Determine the transmission ratio of the worm gear with the vehicle speed (120m / min), the transmission ratio is 1 to 40, the modulus is 2; the next step is to determine the size of the box, the box size is 120MM long X100MM wide X167MM high; the next step is to determine The moving distance of the traverse roller left and right, the moving distance is 35mm; the next step is to determine the center distance of the connecting rod as 135mm.

[0024] Then determine the model of the supporting traverse roller bearing. The linear bearing model is SSE 250 PNWW and the self-aligning ball bearing model is 12210. The other components on the assembly drawing can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com