Cold rolled broken thin strip steel machine starting method

A thin gauge, strip steel technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as cost loss, stable impact on production, and finished products that do not meet thickness requirements, so as to recover economic losses and avoid The effect of breaking the belt again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first step: when the unit produces a 0.5mm thin strip with a thickness of 2.3mm as a raw material, after the strip is broken, the strip is manually threaded first, and the preparations before starting the car are prepared, and the secondary system of the rolling mill In the middle, the thickness of the finished product rolled by the strip is changed to the rolling intermediate thickness value of 0.6mm, and the secondary system is recalculated so that the rolling parameters are implemented in the way of rolling 0.6mm with a raw material thickness of 2.3mm;

[0022] The second step: After the rolling mill starts, observe the thickness change of the rolled strip, when the actual product thickness reaches 0.6±0.05mm, manually operate the rolling mill to stop;

[0023] In the third step, after the rolling mill is stopped, in the secondary system, change the current rolled product thickness 0.6±0.05mm to the rolling target required thickness of 0.5mm, recalculate the secondary ...

Embodiment 2

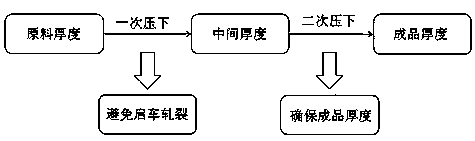

[0026] Such as figure 1 As shown, the first step: when the unit produces a raw material with a thickness of 2.1mm and a rolled product with a thickness of 0.4mm, after the strip is broken, the strip is first manually threaded, and the preparations before starting the car are prepared, and the secondary system In the middle, the thickness of the finished strip rolled by the strip steel is changed to the rolling intermediate thickness value of 0.6mm, and the secondary system is recalculated so that the rolling parameters are implemented in the manner of rolling 0.6mm with a raw material thickness of 2.1mm;

[0027] Step 2: After the rolling mill starts, observe the thickness changes of the rolled strips. When the actual product thickness reaches 0.6±0.05mm, manually stop the operation;

[0028] In the third step, after the rolling mill is stopped, in the secondary system, change the thickness of the currently rolled finished product from 0.6±0.05mm to the target rolling thickness of ...

Embodiment 3

[0031] Such as figure 1 As shown, the first step: when the unit produces raw materials with a thickness of 2.0mm and a rolled product with a thickness of 0.35mm, after the strip is broken, the strip is first manually threaded, and the preparations before starting the car are prepared, and the second system In the middle, the thickness of the finished product rolled by the strip is changed to the rolling intermediate thickness value of 0.6mm, and the secondary system is recalculated so that the rolling parameters are implemented in the manner of rolling 0.35mm with a raw material thickness of 2.0mm;

[0032] Step 2: After the rolling mill starts, observe the thickness changes of the rolled strips. When the actual product thickness reaches 0.6±0.05mm, manually stop the operation;

[0033] In the third step, after the rolling mill is stopped, in the secondary system, change the thickness of the finished product currently rolled from 0.6±0.05mm to the required thickness of the rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com