Self-propelled dual-beam bridge maintenance platform

A maintenance platform, self-propelled technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of reduced construction efficiency, limited adaptability, and impact on bridge traffic, etc., to achieve the effect of convenient installation and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

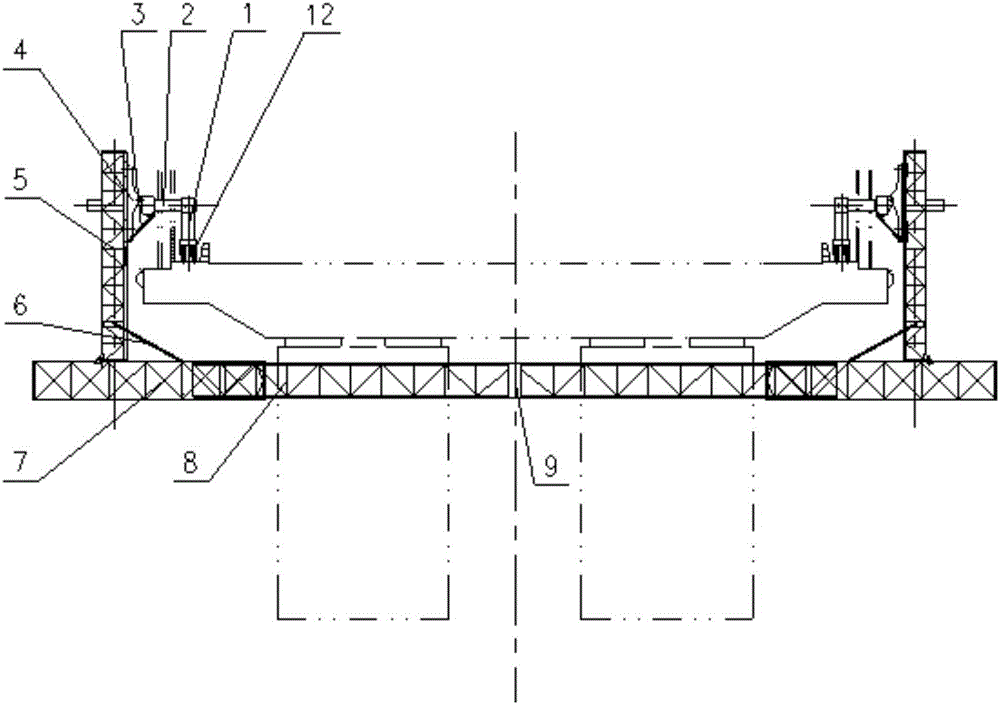

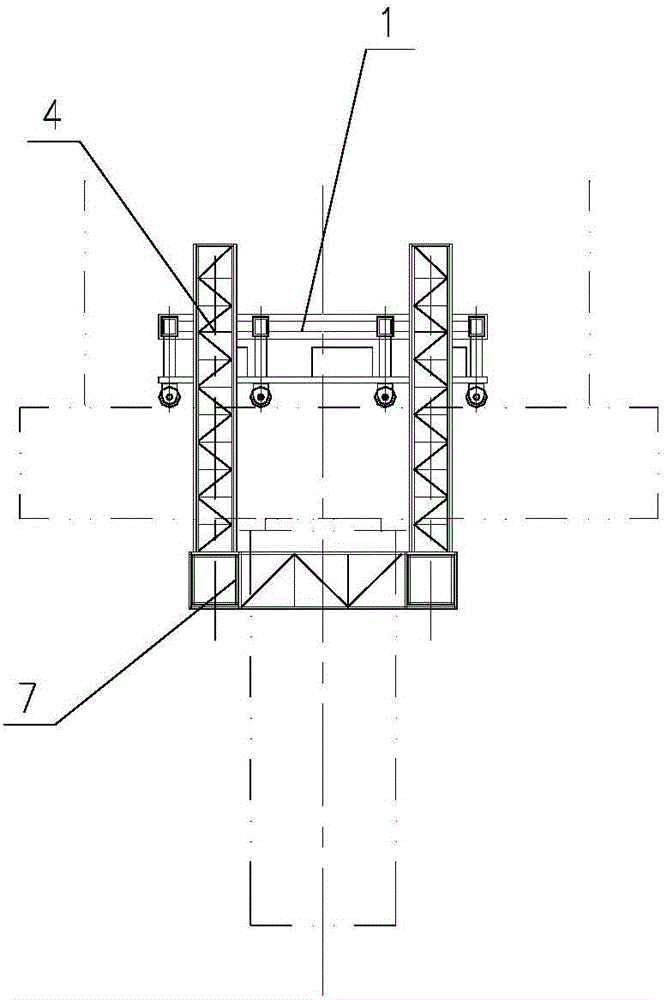

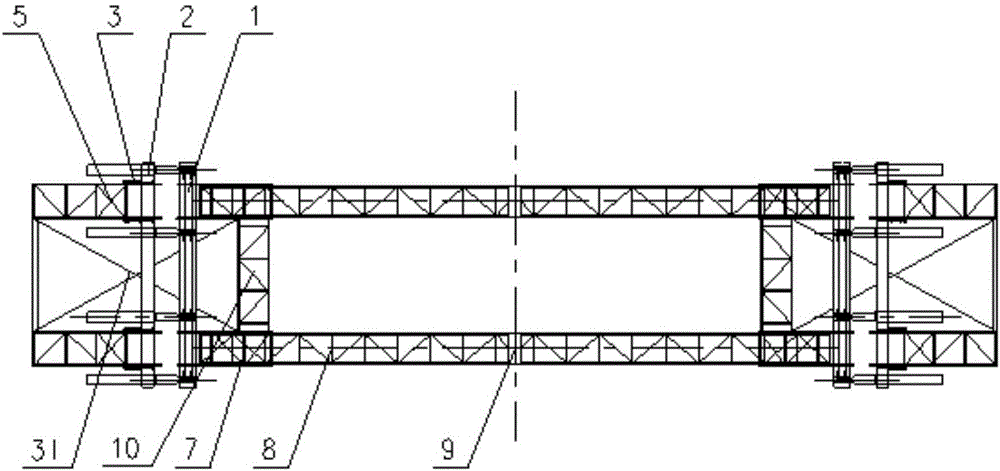

[0027] See attached Figure 1-3 , a self-propelled double-girder bridge inspection platform, which includes: two inspection frame vehicles with the same structure, each inspection frame vehicle includes: bridge deck walking mechanism 1, telescopic arm assembly 2, turning mechanism 4, vertical truss 5, The detection platform fixed frame 7, the detection platform telescopic frame 8 and the docking device 9;

[0028] The bridge deck traveling mechanism 1 includes: two or more traveling trolleys 12 connected by crossbeams 11, and the crossbeams 11 are provided with bolt sleeves 13 and bolt cylinders 14;

[0029] The telescopic arm assembly 2 comprises: more than two fixed arms 21 parallel to each other connected by connecting beams 23, each fixed arm 21 is provided with a telescopic arm 22; Corresponding pin sleeve 13, and locked by the pin oil cylinder 14 there, to realize the connection between the telescopic arm assembly 2 and the bridge deck running mechanism 1;

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com