Ultraviolet photo-curing anti-fog coating and preparation method of same

An anti-fog coating and light-curing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low preheating temperature of UV-cured anti-fog coatings, affecting the light transmittance of transparent materials, and deformation of transparent film materials , to achieve the effects of excellent light transmission, excellent image fidelity, and high surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

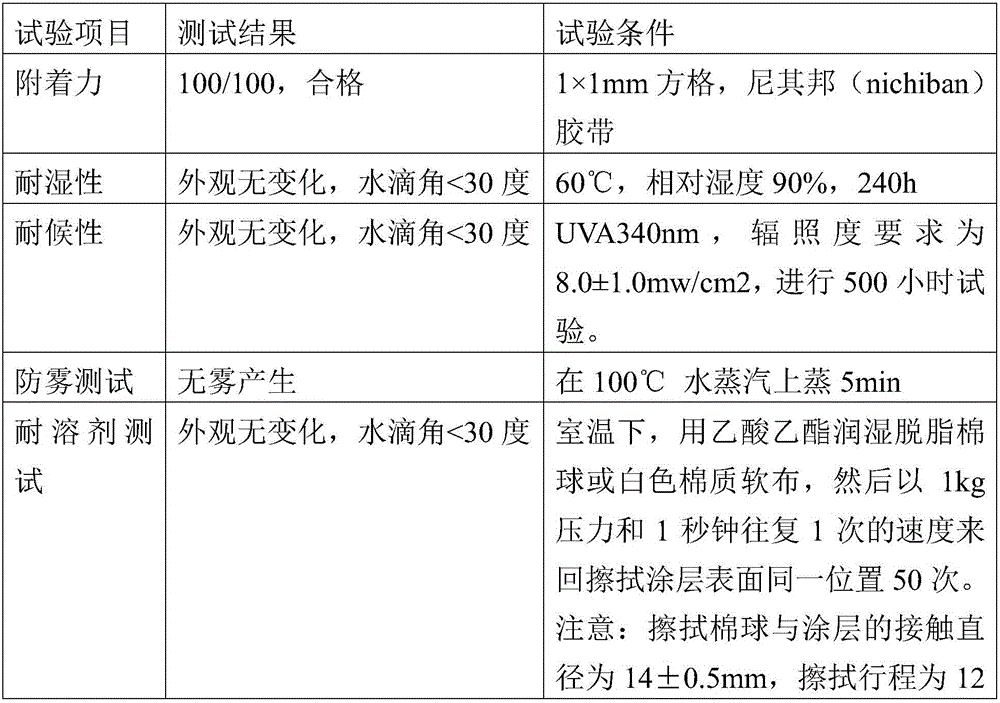

Image

Examples

Embodiment 1

[0026] The ultraviolet photocuring anti-fog coating provided by the applicant consists of the following raw materials:

[0027] Hydrophilic treated silica microspheres: 60g;

[0028] Hydrophilic polymer long chain polyurethane acrylate (model: EB8702): 12g;

[0029] Acetone: 30g;

[0030] Aqueous monomer (HEMA): 12g;

[0031] Photoinitiator (Irgacure 754): 1.2 g.

[0032] The method for hydrophilic treatment of silica microspheres is:

[0033] (1) React silica microspheres with a particle size of 30nm (model: X21-B1022) with isocyanate-type trimethoxysilane, and the reaction molar ratio is controlled at 100:25; the reaction temperature is controlled at 70°C, and the reaction time is 8 hours ;Use HCl as a catalyst, the pH value is adjusted at 3; the stirring speed is controlled at 600rpm;

[0034] (2) React the product obtained in step (1) with hydroxyethyl methacrylate, the molar ratio is controlled at 1:1.2; the reaction temperature is controlled at 80°C, and the reactio...

Embodiment 2

[0039] The ultraviolet photocuring anti-fog coating provided by the applicant consists of the following raw materials:

[0040] Hydrophilic treated silica microspheres: 55g;

[0041] Hydrophilic polymer long chain polyurethane acrylate (model: EB8702): 9g;

[0042] Acetone: 25g;

[0043] Aqueous monomer (HEMA): 10g;

[0044] Photoinitiator (Irgacure 754): 1 g.

[0045] The method for hydrophilic treatment of silica microspheres is:

[0046] (1) React silica microspheres with a particle size of 20nm (model: X21-B1022) with isocyanate-type trimethoxysilane, and the reaction molar ratio is controlled at 100:20; the reaction temperature is controlled at 65°C, and the reaction time is 7 hours ; Use HCl as a catalyst, the pH value is adjusted at 2; the stirring speed is controlled at 550rpm;

[0047] (2) React the product obtained in step (1) with hydroxyethyl methacrylate, the molar ratio is controlled at 1:1.1; the reaction temperature is controlled at 75°C, and the reaction ...

Embodiment 3

[0052] The ultraviolet photocuring anti-fog coating provided by the applicant consists of the following raw materials:

[0053] Hydrophilic treated silica microspheres: 50g;

[0054] Hydrophilic polymer long chain polyurethane acrylate (model: EB8702): 7g;

[0055] Acetone: 20g;

[0056] Aqueous monomer (HEMA): 8g;

[0057] Photoinitiator (Irgacure 754): 0.9 g.

[0058] The method for hydrophilic treatment of silica microspheres is:

[0059] (1) React silica microspheres with a particle size of 15nm (model: X21-B1022) with isocyanate-type trimethoxysilane, and the reaction molar ratio is controlled at 100:15; the reaction temperature is controlled at 60°C, and the reaction time is 6 hours ; Use HCl as a catalyst, the pH value is adjusted at 2; the stirring speed is controlled at 500rpm;

[0060] (2) React the product obtained in step (1) with hydroxyethyl methacrylate, the molar ratio is controlled at 1:1.1; the reaction temperature is controlled at 70°C, and the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com