Wear-resisting anti-aging power cable sheath material and preparation method thereof

A power cable and sheath material technology is applied in the field of wear-resistant and aging-resistant power cable sheath materials and their preparation, and can solve the problems affecting the mechanical strength of the sheath material, the brittleness of the sheath material, and the poor wear resistance and toughness. , to achieve excellent mechanical properties and processing performance, low cost, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

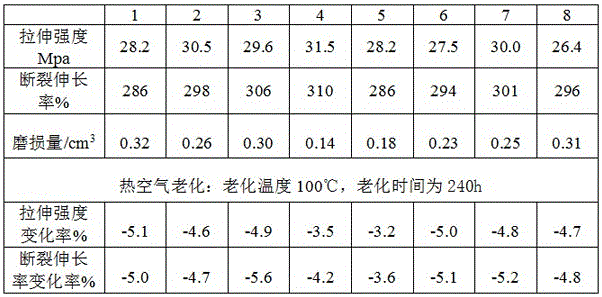

Examples

Embodiment 1

[0027] A wear-resistant and aging-resistant power cable sheath material, comprising the following raw materials in parts by weight: 30 parts of nitrile rubber, 30 parts of polyvinyl chloride, 20 parts of phenolic resin, 10 parts of carbon fiber, 15 parts of carbon black, organic montmorillonite 18 parts, 10 parts of microcrystalline cellulose, 0.5 parts of N,N-phenyl-p-phenylenediamine, 1 part of stearic acid, 10 parts of flame retardant, 3 parts of paraffin, 1 part of anti-aging agent.

[0028] The flame retardant is a mixture of antimony trioxide and aluminum hydroxide in a weight ratio of 2:1.

[0029] Among them, the average particle size of carbon black is 30-32 μm, and the aspect ratio of carbon fiber is 8:1.

[0030] Wherein the anti-aging agent is anti-aging agent MB.

[0031] A preparation method for a wear-resistant and aging-resistant power cable sheath material comprises the following steps:

[0032] (1) Weigh carbon fiber, carbon black, organic montmorillonite a...

Embodiment 2

[0037] A wear-resistant and aging-resistant power cable sheath material, comprising the following raw materials in parts by weight: 32 parts of nitrile rubber, 28 parts of polyvinyl chloride, 22 parts of phenolic resin, 11 parts of carbon fiber, 14 parts of carbon black, organic montmorillonite 17 parts, 11 parts of microcrystalline cellulose, 0.6 parts of N,N-phenyl-p-phenylenediamine, 1.2 parts of stearic acid, 11 parts of flame retardant, 4 parts of paraffin, and 1.1 parts of anti-aging agent.

[0038] The flame retardant is a mixture of antimony trioxide and aluminum hydroxide in a weight ratio of 2:1.

[0039] Among them, the average particle size of carbon black is 30-32 μm, and the aspect ratio of carbon fiber is 8:1.

[0040] Wherein the anti-aging agent is anti-aging agent RD.

[0041] A preparation method for a wear-resistant and aging-resistant power cable sheath material comprises the following steps:

[0042] (1) Weigh carbon fiber, carbon black, organic montmor...

Embodiment 3

[0047] A wear-resistant and aging-resistant power cable sheath material, comprising the following raw materials in parts by weight: 33 parts of nitrile rubber, 27 parts of polyvinyl chloride, 24 parts of phenolic resin, 12 parts of carbon fiber, 13 parts of carbon black, organic montmorillonite 16 parts, 12 parts of microcrystalline cellulose, 0.8 parts of N,N-phenyl-p-phenylenediamine, 1.4 parts of stearic acid, 12 parts of flame retardant, 5 parts of paraffin, and 1.2 parts of anti-aging agent.

[0048] The flame retardant is a mixture of antimony trioxide and aluminum hydroxide in a weight ratio of 2:1.

[0049] Among them, the average particle size of carbon black is 30-32 μm, and the aspect ratio of carbon fiber is 8:1.

[0050] Wherein the anti-aging agent is anti-aging agent H.

[0051] A preparation method for a wear-resistant and aging-resistant power cable sheath material comprises the following steps:

[0052] (1) Weigh carbon fiber, carbon black, organic montmori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com