A constant temperature and humidity air inlet crushing equipment

A constant temperature and humidity, crushing equipment technology, applied in the direction of dispersed particle filtration, membrane filter, membrane technology, etc., can solve the problems of difficult control of pressure difference in the plant, material changes, agglomeration, etc., to reduce the probability of clogging, easy The effect of teleportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

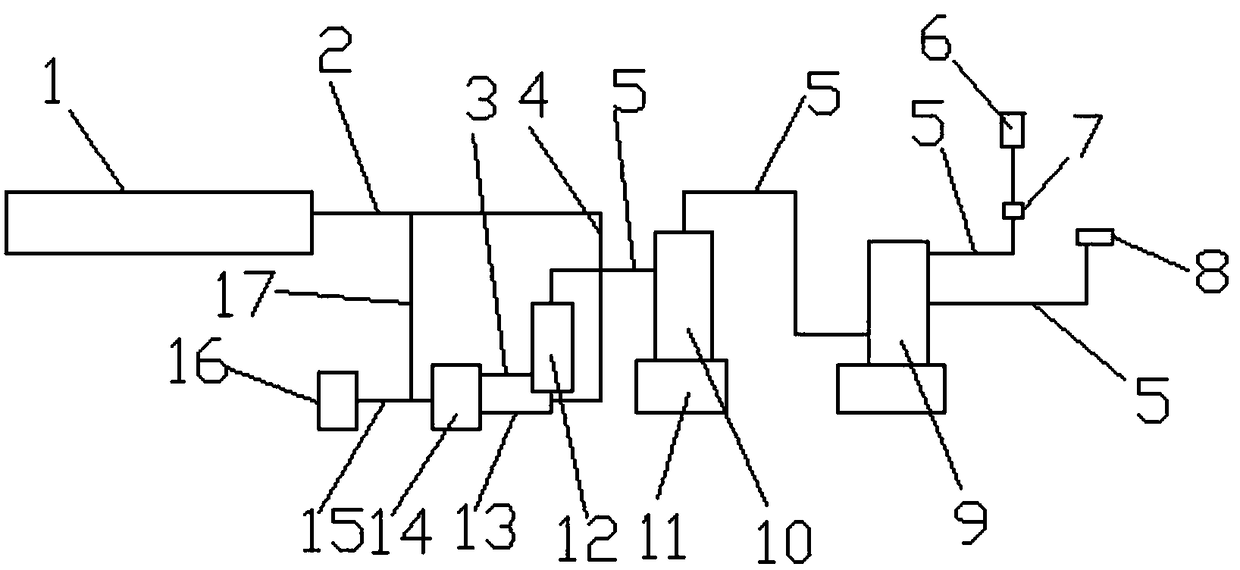

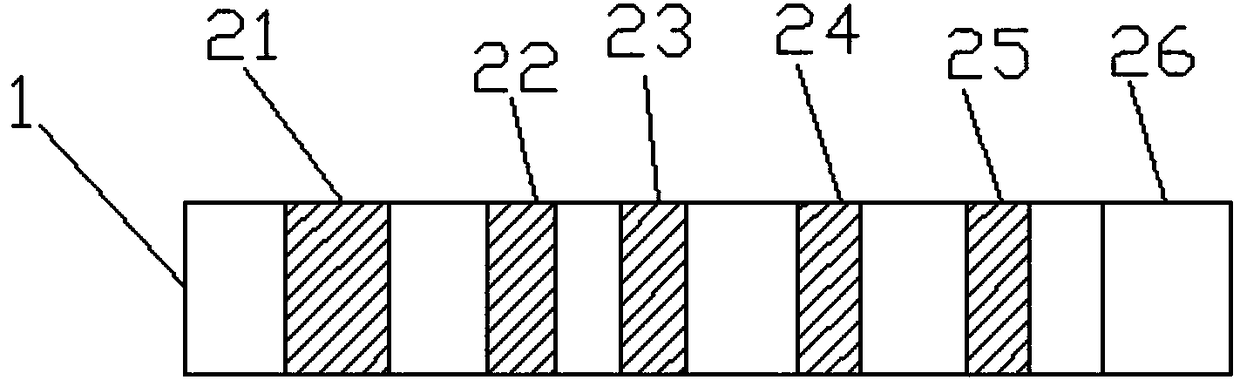

[0020] Embodiment 1. A new type of constant temperature and humidity air inlet crushing equipment, comprising: an air treatment system 1, a first air guide pipe 2, a first material pipe 3, a second air guide pipe 4, a second material pipe 5, a muffler 6, First induced draft fan 7, oil-free air compressor 8, isolation collector 9, cyclone collector 10, receiving bucket 11, classifier 12, third material pipe 13, general-purpose pulverizer 14, fourth material pipe 15, Feeding system 16, third air duct 17, primary filter section 21, medium-effect filter section 22, surface cooling section 23, heating section 24, high-efficiency filter section 25, second induced draft fan 26; among them: air treatment system 1 One end is provided with the first air guide tube 2; one side of the first air guide tube 2 is connected with the fourth material tube 15 through the third air guide tube 17; one side of the first air guide tube 2 is connected with the third material tube through the second ai...

Embodiment 2

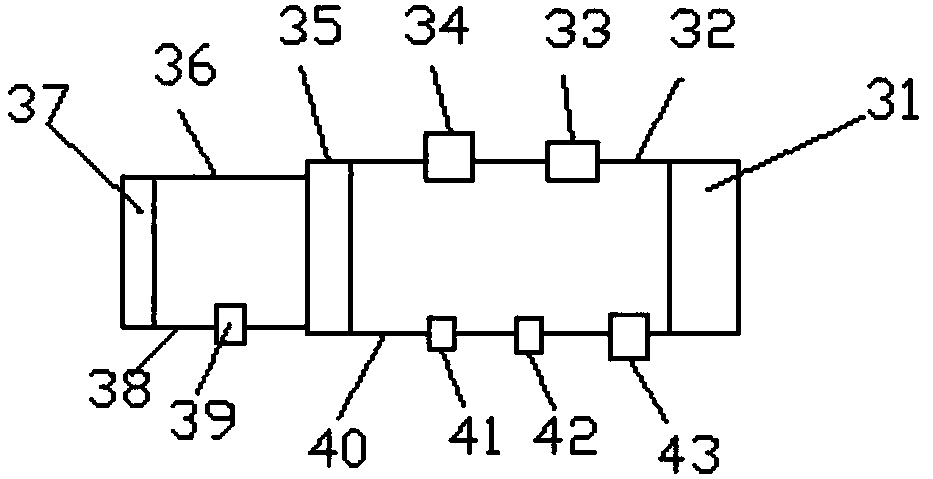

[0021] Embodiment 2. A new type of constant temperature and humidity air inlet crushing equipment, wherein: the left side of the evaporator 31 is connected to the condenser 35 through the first conduit 32; the left side of the evaporator 31 is connected to the condenser 35 through the second conduit 40 ; The first conduit 32 is provided with a compressor 34 and a gas-liquid separator 33 from left to right; the second conduit 40 is provided with a liquid storage tank 41, a dry filter 42, and an expansion valve 43 from left to right; The first water pipe 36 is connected to one side of the water tank 37; the water tank 37 is connected to the condenser 35 through the second water pipe 38; the second water pipe 38 is provided with a water pump 39; the fourth material pipe 15 is arranged in the water tank 37. All the other are with embodiment 1.

Embodiment 3

[0022] Embodiment 3. A new constant temperature and humidity air inlet crushing equipment, wherein: described: the feeding system 16 is composed of a first material storage device 51, a first screw conveyor 52, a discharge pipe 53, a mixer 54, a second A screw conveyor 55, a second material storage device 56, and a primary pulverizer 57 are formed; the bottom of the first material storage device 51 is provided with a first screw conveyor 52; the bottom of the first screw conveyor 52 is provided with a primary pulverizer 57; The primary pulverizer 57 is connected with the agitator 54 through the discharge pipe 53; the bottom of the agitator 54 is provided with a second screw conveyor 55; the bottom of the second screw conveyor 55 is provided with a second storage device 56; the second storage device 56 passes through The fourth feed pipe 15 is connected with the universal pulverizer 14 .

[0023] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com