Fermentation equipment for fruit wine

A fermentation device and fruit wine technology, applied in the field of fruit wine brewing, can solve the problems of destroying the taste of fruit wine, inconvenient production of fruit wine, inconvenient cleaning of residues and sediments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

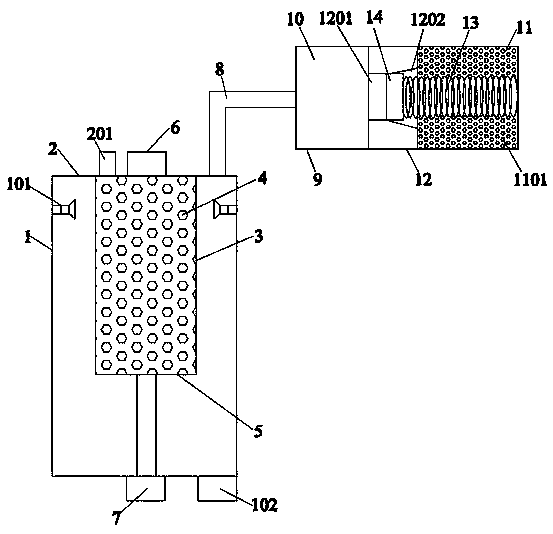

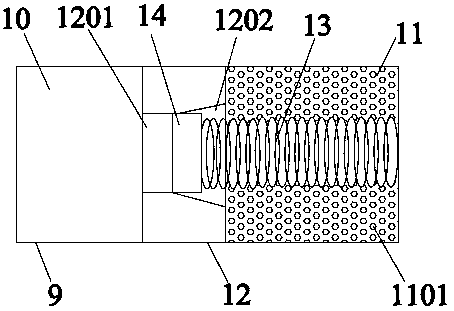

[0026] As can be seen from the drawings, a fermentation device for fruit wine includes a fermentation tank, a separation device, an adjustment device, and a gas balance device; the fermentation tank includes a tank body 1 and a sealing cover 2, and a cleaning pipe is arranged in the tank body 1 101. The cleaning pipe 101 is located at the top of the tank body 1. A spray head is arranged on the cleaning pipe 101, which can rotate to spray direction. The bottom of the tank body 1 is provided with a discharge port 102, and the sealing cover 2 is arranged above the tank body 1. Used to seal the tank 1;

[0027] The separation device includes a motor 6, a stirring paddle 601, and a separation drum 3. The separation drum 3 is arranged in the fermentation tank, and the separation drum 3 is installed below the sealing cover 2, and a hopper is arranged above the sealing cover 2 201. The bottom of the feed hopper 201 is communicated with the separation cylinder 3. The separation cylinder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com