High pressure powder feeder unit and application thereof

A powder feeder and high-pressure technology, applied in conveyors, conveying bulk materials, metal material coating processes, etc., can solve problems such as insufficient sealing effect, insufficient powder feeding accuracy, and equipment difficult to meet production process requirements, etc. To achieve the effect of good sealing effect, safe and reliable use, and economical and applicable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

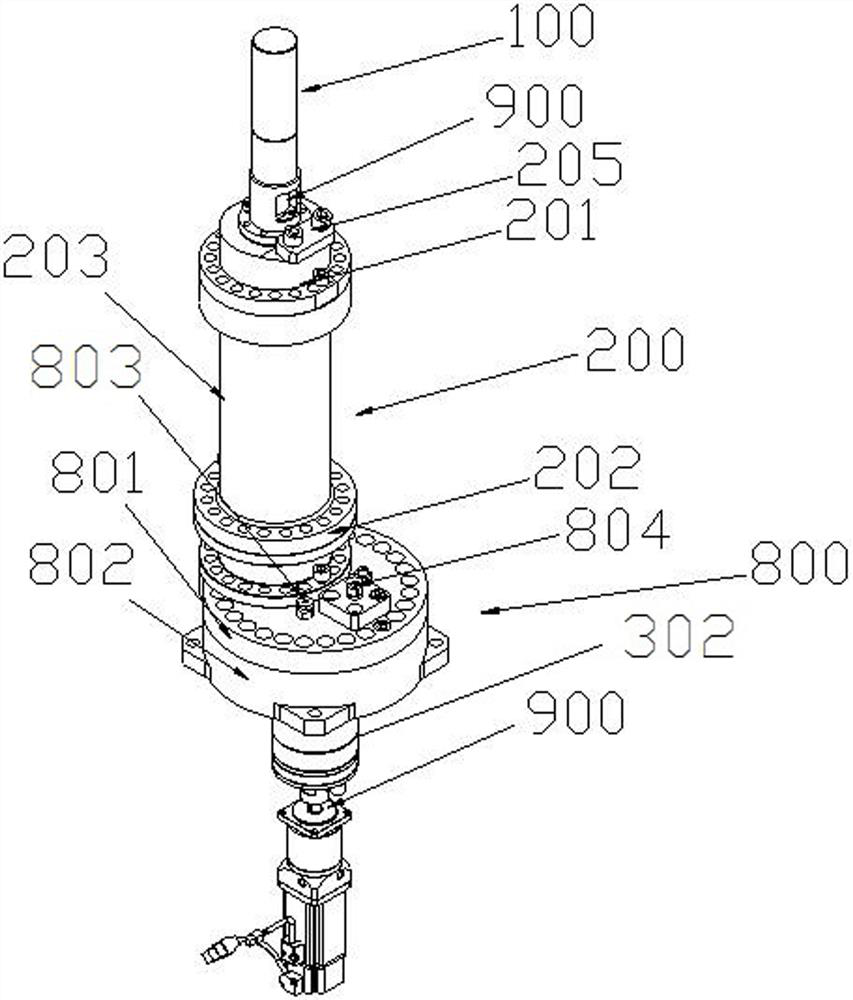

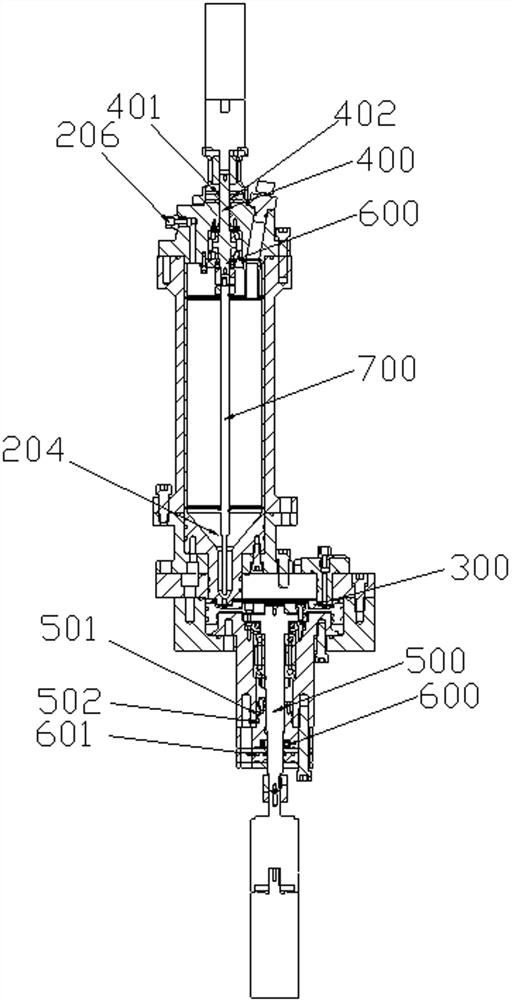

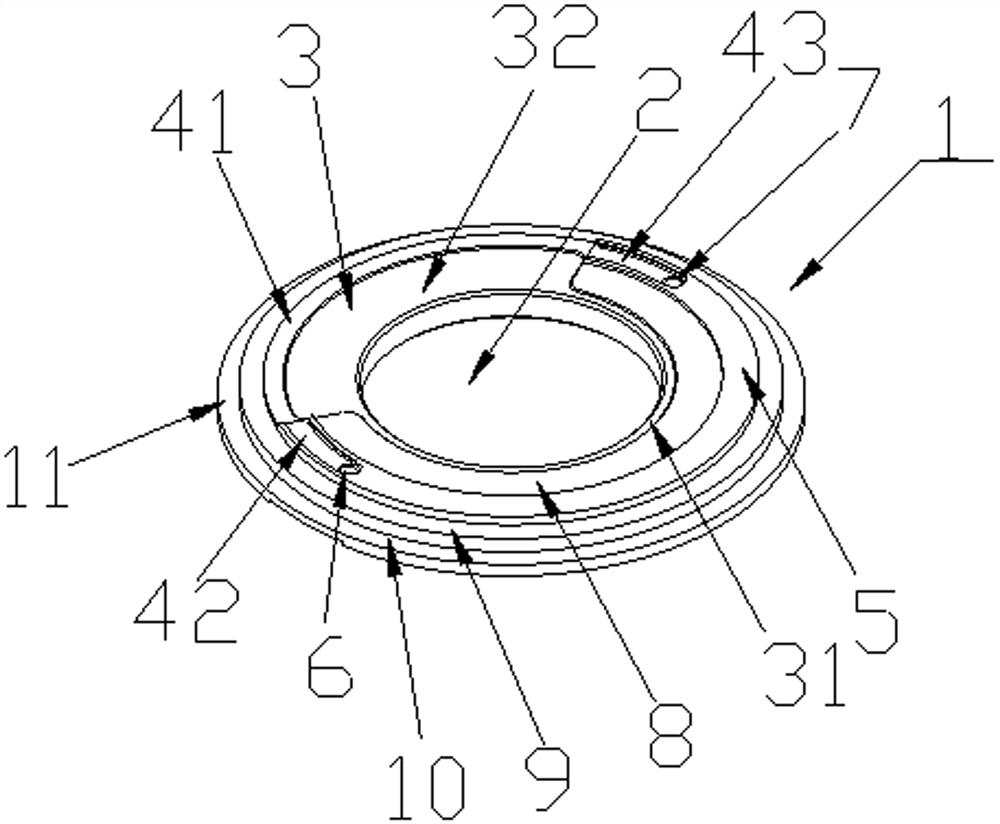

[0046] Such as Figure 1~Figure 6 As shown, the high-pressure powder feeder unit includes a drive unit 100, a powder storage unit 200 and a powder tray unit 300 arranged in sequence, and the output end of the drive unit 100 is connected with a drive shaft 400 extending into the powder storage unit 200. In this implementation The drive unit 100 in the example is a DC motor, one end of the drive shaft 400 is connected to the output end of the motor through a coupling 900, the other end of the coupling 900 is connected to a powder stirring rod 700, and the powder storage unit 200 includes a powder storage tank body 203 and an installation The upper end cap 201 and the lower end cap 202 at both ends of the powder storage tank body 203; the outer edge diameters of the upper and lower end caps are larger than the outer wall diameter of the powder storage tank body 203, and the structure of the powder storage tank body 203 is a cylinder with connecting ears , the connecting ear and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com