3D printing forming method for metal dental restoration

A technology of 3D printing and molding method, applied in the field of 3D printing, can solve the problems such as chemical impurities easily embedded in the crown, the accuracy and quality error of the restoration, affecting the accuracy and the metal-ceramic bonding force, etc., to avoid trachoma and shrinkage defects. , The effect of shortening the production cycle and reducing human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

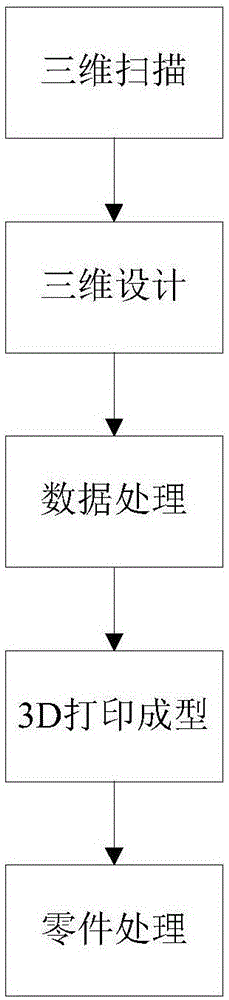

[0031] Take the preparation of cobalt-chromium alloy inner crown as an example. Such as figure 1 The 3D printing molding method of the dental metal restoration of the present invention is shown, and its features include:

[0032] Three-dimensional scanning: Through the blue light scanning method, high-precision scanning data can be obtained, and precise scanning of various small features in the oral cavity can be realized, and the scanning accuracy can reach within 5 μm. Obtain the patient's oral situation by directly scanning the oral cavity, and send the scanned three-dimensional data directly to the dental processing factory to improve the consistency of the restoration process.

[0033] Three-dimensional design: import the three-dimensional data of the patient's oral cavity into the 3shape dental design software, and carry out the three-dimensional design of the metal restoration according to the shape of the abutment teeth and the shape of the gums, and according to the ...

Embodiment 2

[0041] Taking the preparation of a TC4 titanium alloy stent as an example, on the basis of Example 1, the three-dimensional scanning adopts plaster model scanning to obtain the internal data of the oral cavity. After the impression is taken out from the patient's mouth by quick-setting materials such as silicone rubber, a plaster model is poured through the impression, and then the three-dimensional shape of the plaster model is scanned by a blue-ray scanner to obtain three-dimensional data of the oral cavity.

[0042] The exocad dental design software was used for the three-dimensional design, and the metal restoration was designed according to the shape of the abutment teeth, the shape of the gingiva and the condition of the jaw.

[0043] During data processing, the obtained restoration STL format file is imported into the CAMbridge data processing software, and the steps of data inspection and restoration, position placement, support addition, slicing and scanning strategy p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com