Preparation method of nitrogen-doped porous carbon foam material and application of nitrogen-doped porous carbon foam material in metal-air battery

A nitrogen-doped porous carbon and foam material technology is applied in fuel cell-type half-cells and secondary-battery-type half cells, battery electrodes, circuits, etc. Achieve the effect of rich pore structure, good mechanical and electrochemical properties, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 5g of chitin and dissolve it in 5mL of water, mix and stir for 10min at a stirring speed of 300rpm until the solution is homogeneous and stable, and record it as beaker a; measure 50mL of concentrated sulfuric acid in beaker b, then slowly add concentrated sulfuric acid into beaker a In the process, until the amount of black solid is produced no longer increases. Pour the beaker with the black solid into a large beaker filled with water, filter and wash until the filtrate is neutral. The filtered black solid was put into a freeze dryer and dried for 12 hours.

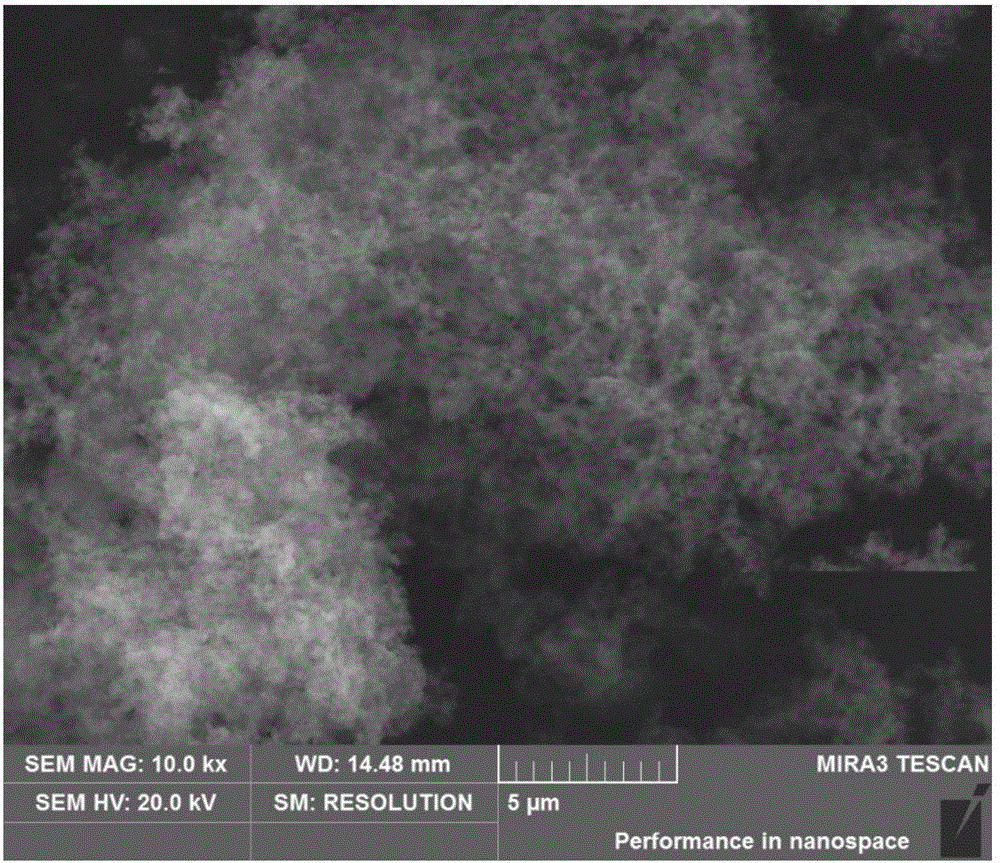

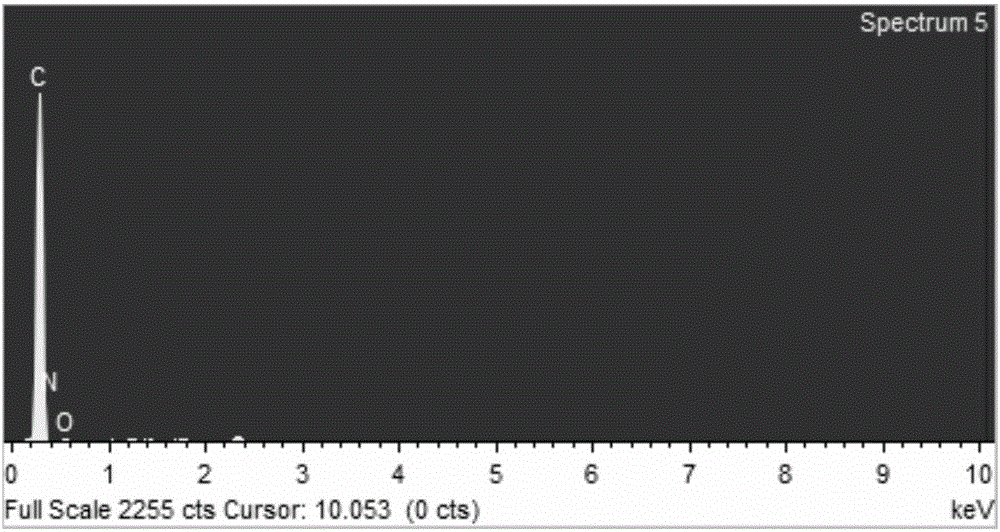

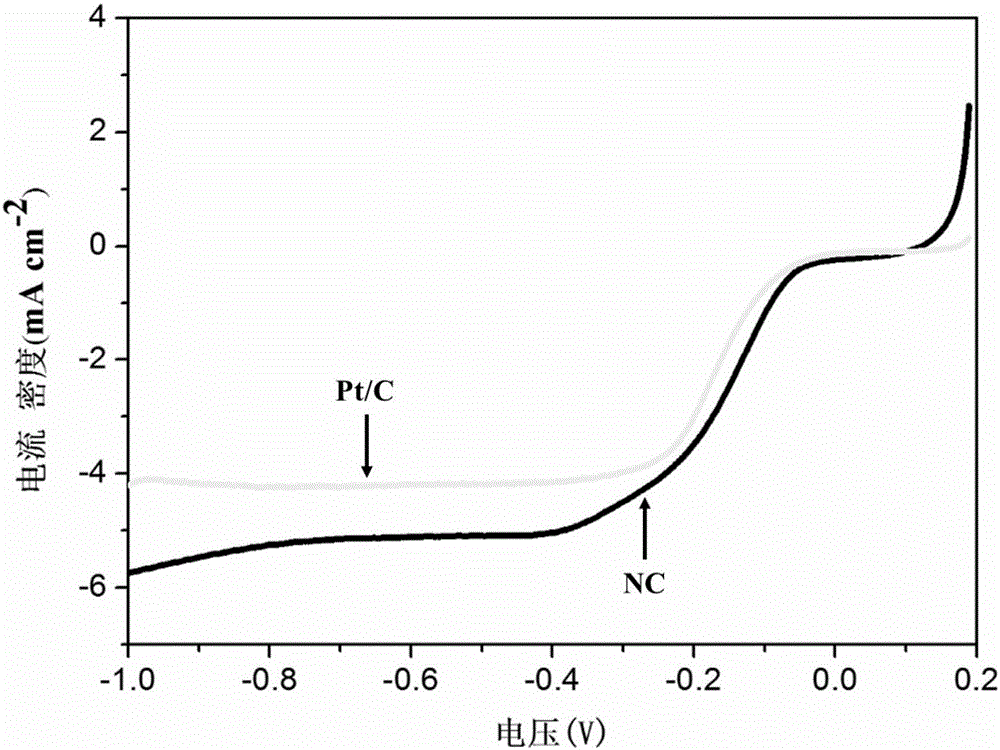

[0035] The prepared material precursor was placed under an argon atmosphere, and the temperature was raised to 900° C. at a heating rate of 5° C. / min, and kept for 2 hours. The obtained material is the N-doped porous carbon foam material (see the SEM image in figure 1). figure 1 It can be seen that the synthesized material has a rich pore structure, figure 2 The EDS results show that the material conta...

Embodiment 2

[0040] Weigh 10g of chitin and dissolve it in 5mL of water. After mixing, stir at a stirring speed of 300rpm for 10min until the solution is uniform and stable, which is recorded as beaker a; measure 60mL of concentrated sulfuric acid into beaker b, and then slowly add concentrated sulfuric acid into beaker a In the process, until the amount of black solid is produced no longer increases. Pour the beaker with the black solid into a large beaker filled with water, filter and wash until the filtrate is neutral. The filtered black solid was put into a freeze dryer and dried for 12 hours.

[0041] The prepared material precursor was placed under an argon atmosphere, and the temperature was raised to 800° C. at a heating rate of 4° C. / min, and kept for 2 hours. The obtained material is N-doped porous carbon foam material, and its specific surface area reaches 1000 m 2 / g, N doping amount is 7%.

[0042] The catalyst material prepared in this embodiment is mixed with ethanol and ...

Embodiment 3

[0044] Weigh 10g of chitin and dissolve it in 10mL of water. After mixing, stir at a stirring speed of 500rpm for 10min until the solution is uniform and stable, which is recorded as beaker a; measure 50mL of concentrated sulfuric acid into beaker b, and then slowly add concentrated sulfuric acid into beaker a In the process, until the amount of black solid is produced no longer increases. Pour the beaker with the black solid into a large beaker filled with water, filter and wash until the filtrate is neutral. The filtered black solid was put into a freeze dryer and dried for 12 hours.

[0045] The prepared material precursor was placed under an argon atmosphere, and the temperature was raised to 700° C. at a heating rate of 5° C. / min, and kept for 2 hours. The obtained material is N-doped porous carbon foam material, and its specific surface area reaches 728m 2 / g, N doping amount is 5%.

[0046] The catalyst material prepared in this embodiment is mixed with ethanol and N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com