A kind of oil washing agent for oil well fracturing and its preparation method and application

An oil washing agent and oil well technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve high oil washing efficiency, good oil washing effect, and improved oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

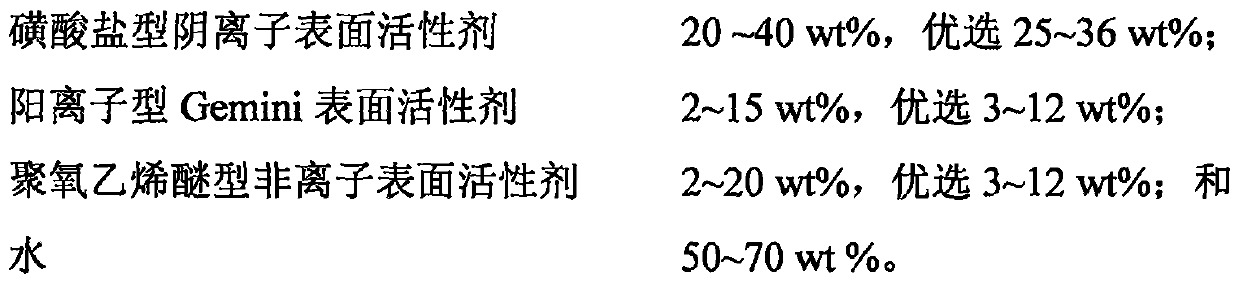

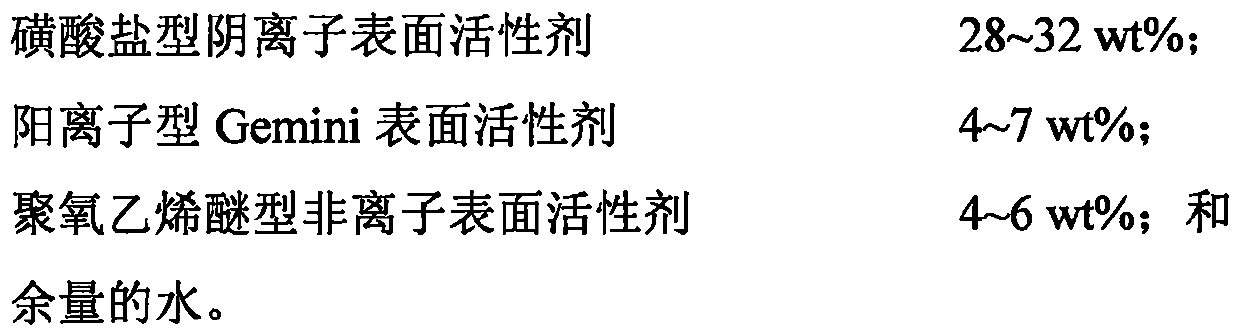

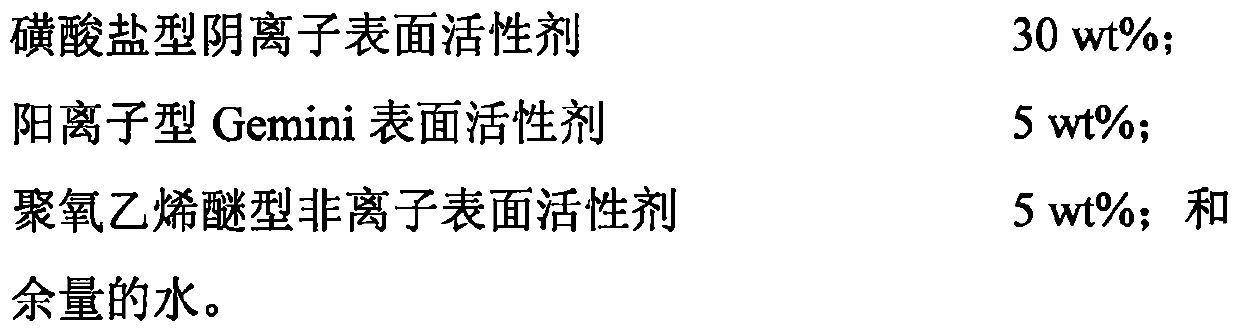

Method used

Image

Examples

Embodiment 1

[0058] at 2m 3 Add 600kg of tap water, stir at room temperature, add 50kg of dihexadecyl dimethyl ammonium bromide (Yixing Chemical Factory) at one time, nonylphenol polyoxyethylene ether-10 (OP-10) (Guangzhou Ruiyang Surfactant Co., Ltd.) 50kg, after stirring for 30 minutes, add 300kg of sodium dodecyl benzene sulfonate (Guangzhou Ruiyang Surfactant Co., Ltd.), and continuously stir for 30 minutes to obtain the cleaning agent of the present invention. Oil products.

[0059] Take an appropriate amount of this oil washing agent product and add it to the fracturing fluid (containing hydroxypropyl guar: 0.05wt%-0.15wt%; clay stabilizer: 0.3wt%-1.2wt%; drainage aid: 0.3wt%- 1.0 wt%; and water), so that the concentration of the wash oil is 0.1 wt%. The interfacial tension of the fracturing fluid was measured by an automatic surface tensiometer K100C (KRUSS, Germany), which was 3 mN / m, and the contact angle was measured by a contact angle measuring instrument JC2000C (Shanghai Zho...

Embodiment 2

[0070] at 2m 3 In the reaction kettle of 500kg, add 500kg oil field re-injection water, stir at room temperature, add dihexadecyl dimethyl ammonium bromide 50kg at one time, OP-1050kg, stir after 40 minutes, add 300kg sodium petroleum sulfonate (Zhejiang Shaoxing County Nanfang Petrochemical Co., Ltd.), stirring continuously for 30 minutes to obtain the oil-washing agent product of the present invention.

[0071] The oil washing agent product is taken and added to the fracturing fluid, so that the concentration of the oil washing agent is 0.1 wt %. The interfacial tension of the fracturing fluid was measured to be 4.5 mN / m and the contact angle was 12°. The fracturing fluid was added to the oil washing device containing the same batch of saturated cores as in Example 1 (core parameters: sandstone, diameter 24.99mm, length 49.98mm, permeability 1.1346mD, porosity 12.83%), and after imbibition for one week The oil wash rate is 38%.

Embodiment 3

[0073] at 2m 3 Add 500kg of tap water, stir at room temperature, add 80kg of dihexadecyl dimethyl ammonium bromide at one time, fatty alcohol polyoxyethylene (7) ether (AEO-7) (Guangzhou Ruiyang) After 50kg of surfactant Co., Ltd. was stirred for 20 minutes, 300kg of octyl sulfonate (Guangzhou Ruiyang Surfactant Co., Ltd.) was added, and the mixture was continuously stirred for 40 minutes to obtain the oil-washing product of the present invention.

[0074] Take an appropriate amount of the oil washing agent product and add it to the fracturing fluid, so that the concentration of the oil washing agent is 0.12 wt %. The interfacial tension of the fracturing fluid was measured to be 5.2 mN / m and the contact angle was 18°. The fracturing fluid was added to the oil washing device containing saturated core (core parameters: carbonate rock, diameter 25.02 mm, length 50.33 mm, permeability 0.1637 mD, porosity 8.31%), and the oil washing rate after imbibition for one week was 31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com