Method and device for utilizing dynamic magnetic stirring paddle to prepare vaterite

A technology of magnetic stirring and vaterite, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve the problems of increased production cost, complicated operation process, cumbersome process, etc., and achieve strong magnetic field and high product quality The effect of high purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is aimed at the low concentration of Na 2 CO 3 The reaction solution was subjected to the preparation of vaterite.

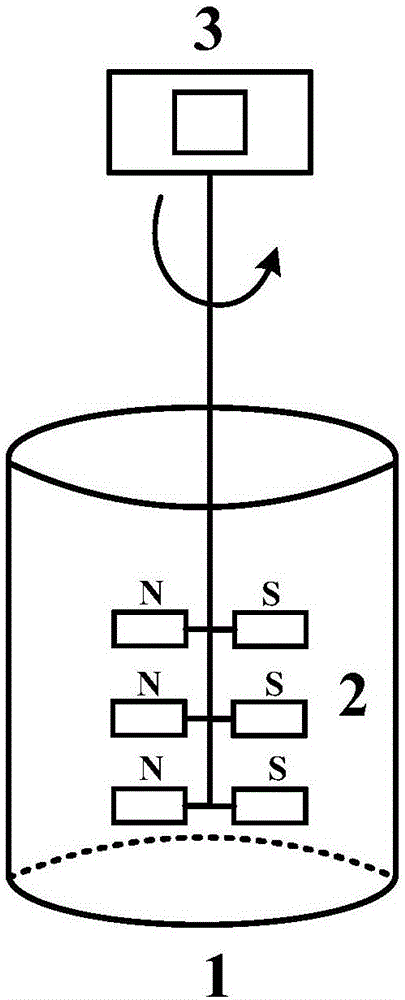

[0036] A magnetic stirring paddle is installed in the reactor, and the magnetic stirring paddle is connected with a controller to control the rotation speed of the magnetic stirring paddle, and the stirring of the magnetic stirring paddle is used to mix the reaction solution evenly. The magnetic induction of the permanent magnet on the magnetic stirring paddle is 2000 Gauss.

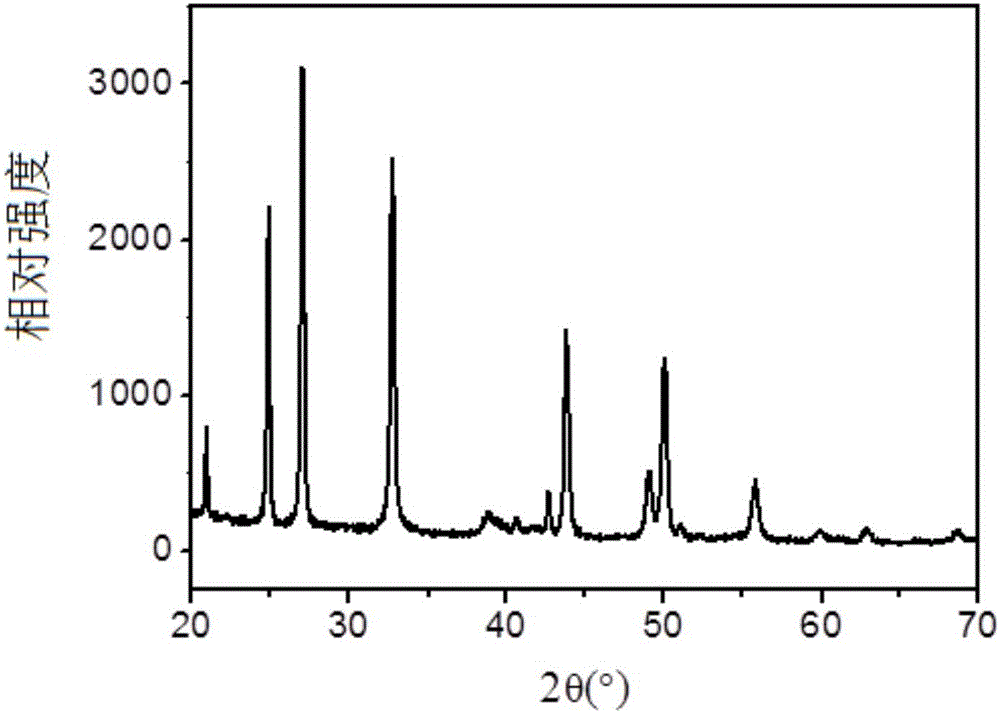

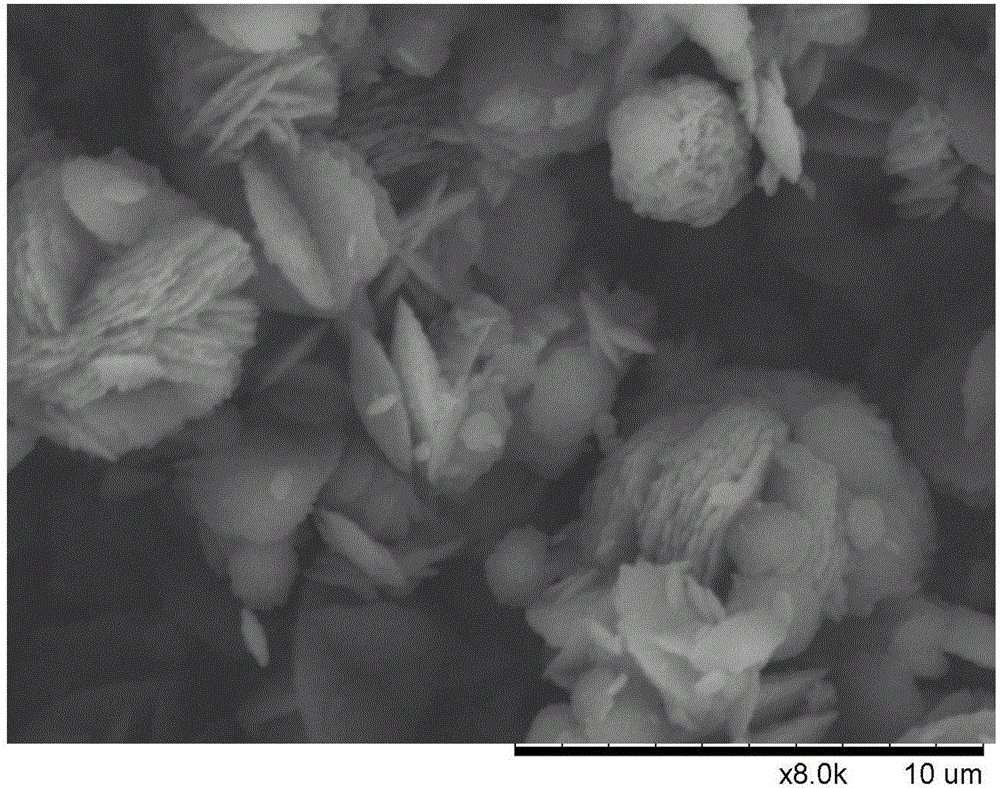

[0037] Turn on the controller, and mix 15ml of Na with a concentration of 0.005mol / L at a stirring rate of 300 rpm 2 CO 3 The solution is introduced into the reactor at a uniform speed at a rate of 1.0ml / min, and the concentration is 0.005mol / L of 15ml CaCl 2 in solution. Under the stirring action of the magnetic stirring paddle, the reaction solution cuts the strong magnetic field formed by the permanent magnet on the stirring paddle. The rotating stirring magn...

Embodiment 2

[0041] This embodiment is aimed at the NaHCO of low concentration 3 Reaction solution, change the magnetic treatment conditions, and carry out the preparation of vaterite.

[0042] A magnetic stirring paddle is installed in the reactor, and the magnetic stirring paddle is connected with a controller to control the rotation speed of the magnetic stirring paddle, and the stirring of the magnetic stirring paddle is used to mix the reaction solution evenly. The magnetic induction of the permanent magnet on the magnetic stirring paddle is 3000 Gauss.

[0043] Turn on the controller, and mix 150ml of NaHCO with a concentration of 0.005mol / L at a stirring rate of 500 rpm. 3 The solution is introduced into the reactor at a uniform speed at a rate of 7.5ml / min and is 75ml of CaCl with a concentration of 0.005mol / L 2 in solution. Under the stirring action of the magnetic stirring paddle, the reaction solution cuts the strong magnetic field formed by the permanent magnet on the stirri...

Embodiment 3

[0047] This embodiment is aimed at high concentrations of Na 2 CO 3 The reaction solution was used to prepare vaterite.

[0048] A magnetic stirring paddle is installed in the reactor, and the magnetic stirring paddle is connected with a controller to control the rotation speed of the magnetic stirring paddle, and the stirring of the magnetic stirring paddle is used to mix the reaction solution evenly. The magnetic induction of the permanent magnet on the magnetic stirring paddle is 4000 Gauss.

[0049] Turn on the controller, and at a stirring rate of 800 rpm, mix 150ml of Na with a concentration of 0.1mol / L 2 CO 3 The solution is 150ml CaCl with a concentration of 0.1mol / L introduced into the reactor at a uniform speed at a rate of 7.5ml / min 2 in solution. Under the stirring action of the magnetic stirring paddle, the reaction solution cuts the strong magnetic field formed by the permanent magnet on the stirring paddle. The rotating stirring magnetic field promotes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com