Vertical type pressurizing roasting pot

A roasting and vertical technology, which is applied in the field of high-pressure roasting tanks, can solve the problems of high-end carbon products that cannot meet the high-temperature and high-pressure roasting environment, and achieve the effects of shortening roasting time, high density, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

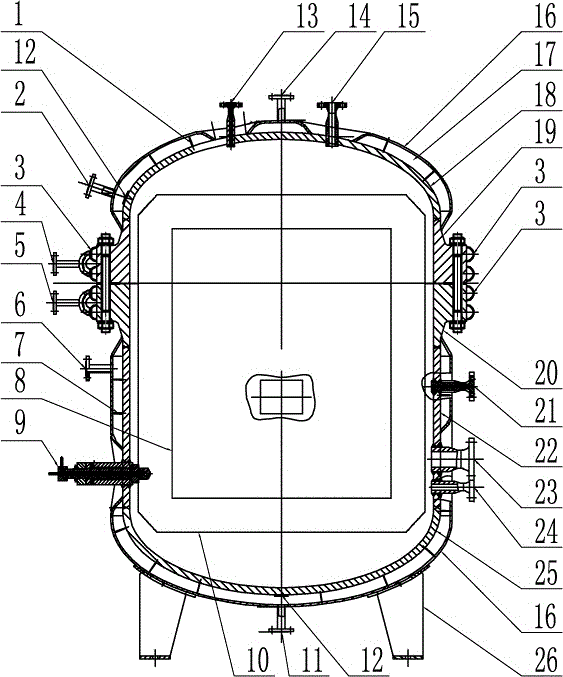

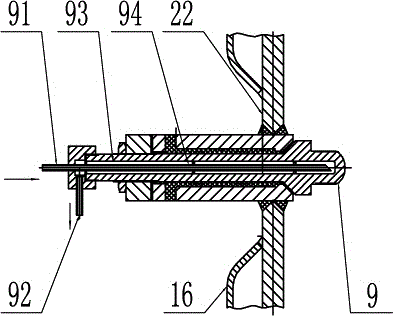

[0016] like figure 1 As shown, the vertical pressurized roasting tank of the present invention comprises a high-pressure tank body with an upper end cap 18 and a lower end cap 25, a firing box 8 is provided in the tank body, and a ceramic fiber felt protection is provided on the outer surface of the firing box. Layer 10 is provided with a safety valve connection 15, a direct reading pressure gauge connection 13, a remote pressure gauge connection 21, a vacuuming connection 23, and a nitrogen pressurization connection 24 on the tank body. The tank body is composed of an upper tank body and a lower tank body that are butted together. The upper tank body is formed by welding the upper head 18 and the equipment flange 19, and the lower tank body is composed of the lower head 25, the cylinder body 22, the equipment The flange is welded by 20 groups, and the equipment flanges of the upper tank and the lower tank are sealed and matched. There are fastening screw holes in an annular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com