A new type of car light dimming screw and its manufacturing method

A manufacturing method and screw technology, applied in the direction of fixing screws, motor vehicles, light sources, etc., can solve the problems of inability to ensure the balance of product adjustment lamps, and difficulty in rotating a single product on the same axis, so as to achieve structural stability, reduce product costs, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with implementation examples and accompanying drawings.

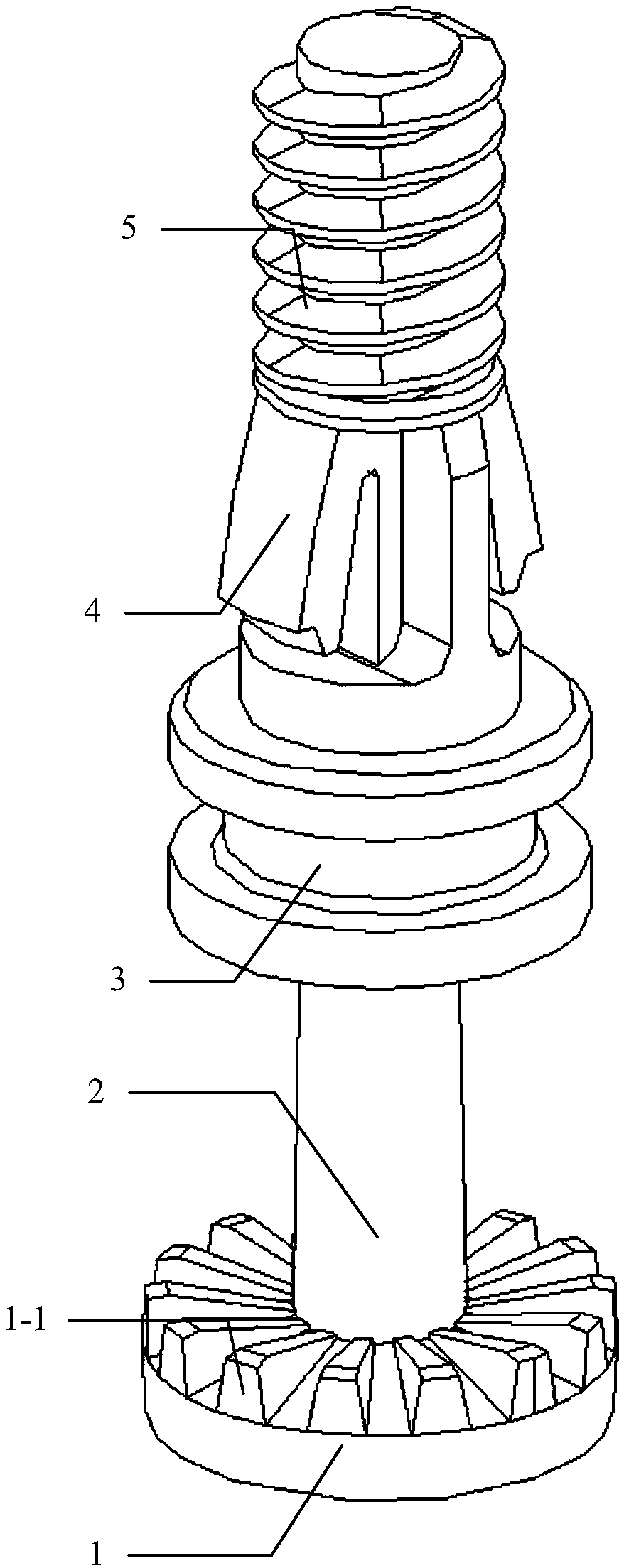

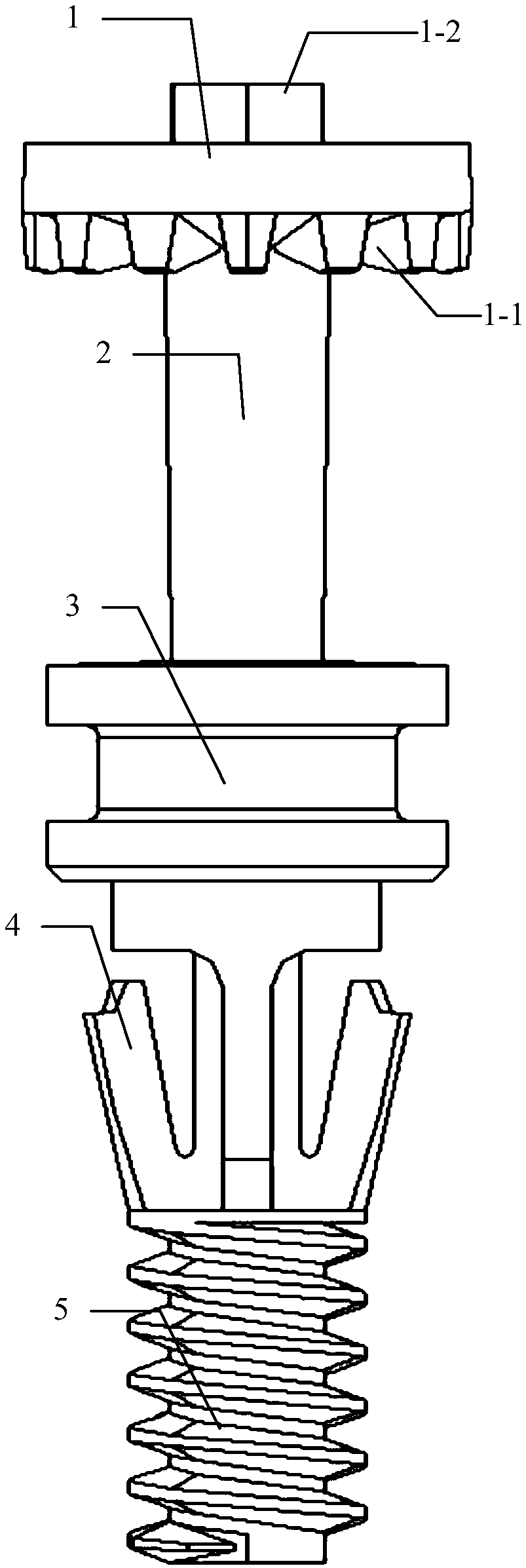

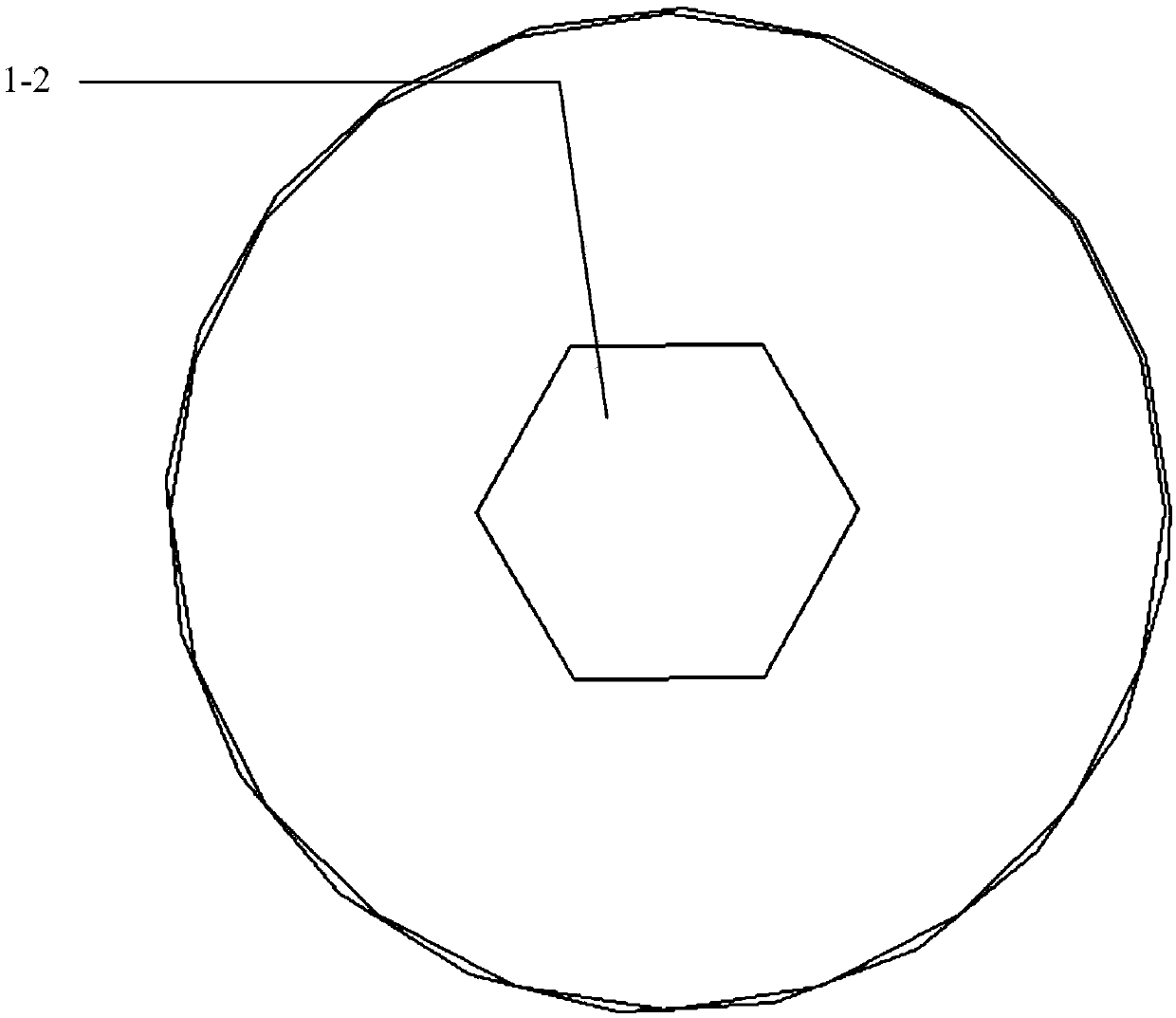

[0028] A new type of car light dimming screw, such as figure 1 As shown, the integral columnar structure includes a screw head 1, a screw rod 2, and a thread 5. Described screw head 1 is arranged on screw rod 2 one ends, and described thread 5 is located on screw rod 2; Described screw rod 2 is provided with buckle 4, and buckle 4 is connected with screw rod 2 as a whole; Described screw rod 2 is provided with The recessed ring groove 3 for installing the sealing washer; starting from the screw head 1, the whole new car light dimming screw is arranged in sequence according to the order of the screw head 1, the recessed ring groove 3 for installing the sealing washer, the buckle 4, and the thread 5. Such as figure 2 As shown in the side view of the novel car lamp dimming screw of the present invention, the lower surface of the screw head 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com