Method for preparing semi-dull and full-dull titanium polyester through adding titanium dioxide

A technology of titanium-based polyester and titanium dioxide, which is applied in the field of preparing semi-dull and full-dull titanium-based polyester by adding titanium dioxide, which can solve the problems of uneven addition, inaccurate catalyst measurement, and inability to produce polyester with qualified viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 42.6g tetraisopropyl titanate (0.15mol), 93.0g ethylene glycol (1.5mol), 5.8g sodium p-toluenesulfonate (0.03mol) to the reactor equipped with stirrer, separatory funnel and condenser ) and 3.0 g of sodium hydroxide (0.075 mol), the temperature was gradually increased from 30 ° C to 200 ° C for 1 hour, and the reaction system became a homogeneous liquid after removing low-boiling small molecular substances, and catalyst A was obtained.

[0029] Preparation of semi-dull titanium-based polyester

[0030] With 500g terephthalic acid (PTA), 270g ethylene glycol (EG) and catalyst A (based on the amount of the polyester that generates, the weight content of titanium atom is 5 * 10 -6 ), add 2L polymerization reactor. The esterification reaction is carried out under the conditions of 230°C-260°C and 0-0.4MPa. When the amount of distilled water reaches more than 95% of the theoretical value, the esterification is over, and 1.4g of titanium dioxide is added to the esterific...

Embodiment 2

[0033] Add 42.6g tetraisopropyl titanate (0.15mol), 13.8g glycerol (0.15mol), 2.6g sodium dodecylsulfonate ( 0.0075 mol) and 1.6 g of sodium carbonate (0.015 mol), the temperature was gradually increased from 30°C to 200°C for 1 hour, and the reaction system became a homogeneous liquid after removing small molecular substances with low boiling points, and catalyst B was obtained.

[0034] Preparation of full-dull titanium-based polyester

[0035] With 500g terephthalic acid (PTA), 270g ethylene glycol (EG) and catalyst B (based on the amount of the polyester that generates, the weight content of titanium atom is 50 * 10 -6), add 2L polymerization reactor. The esterification reaction is carried out under the conditions of 230°C-260°C and 0-0.4MPa. When the amount of distilled water reaches more than 95% of the theoretical value, the esterification is over, and 16.5g of titanium dioxide is added to the esterification product (to generate The amount of polyester is 3.0%). After...

Embodiment 3

[0038] Add 25.8g of tetramethyl titanate (0.15mol), 135g of 1,4-butanediol (1.5mol), 10.9g of potassium dodecylsulfonate to the reactor equipped with stirrer, separatory funnel and condenser (0.03mol) and 10.4g salt of wormwood (0.075mol), at 30 ℃ gradually warming up to 200 ℃ for 1 hour, reaction system becomes homogeneous liquid after removing low-boiling point small molecules, obtains catalyst C.

[0039] Preparation of semi-dull titanium-based polyester

[0040] Adopt the same method as embodiment 1 to prepare polyester, use catalyst C as catalyst (based on the amount of the polyester of generation, the weight content of titanium atom is 5 * 10 -6 ).

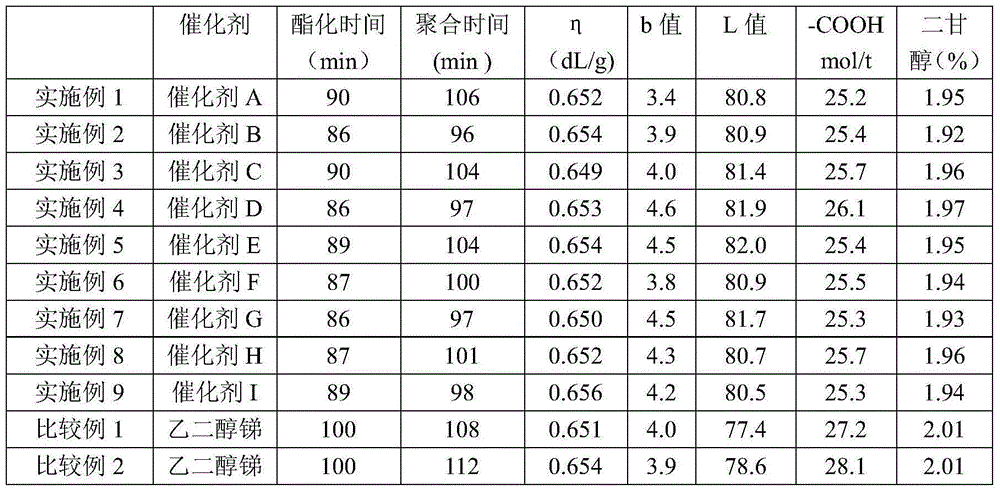

[0041] The synthetically obtained semi-dull polyester product was tested for performance, and the esterification, polymerization time and analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com