Screening method for lithium iron phosphate battery cell

A single battery and lithium iron phosphate technology, applied in sorting and other directions, can solve the problems of battery consistency screening deviation, few battery measurement parameters, and inability to explain the current state of the battery well, so as to improve the safety and energy of use Excellent utilization rate, consistency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

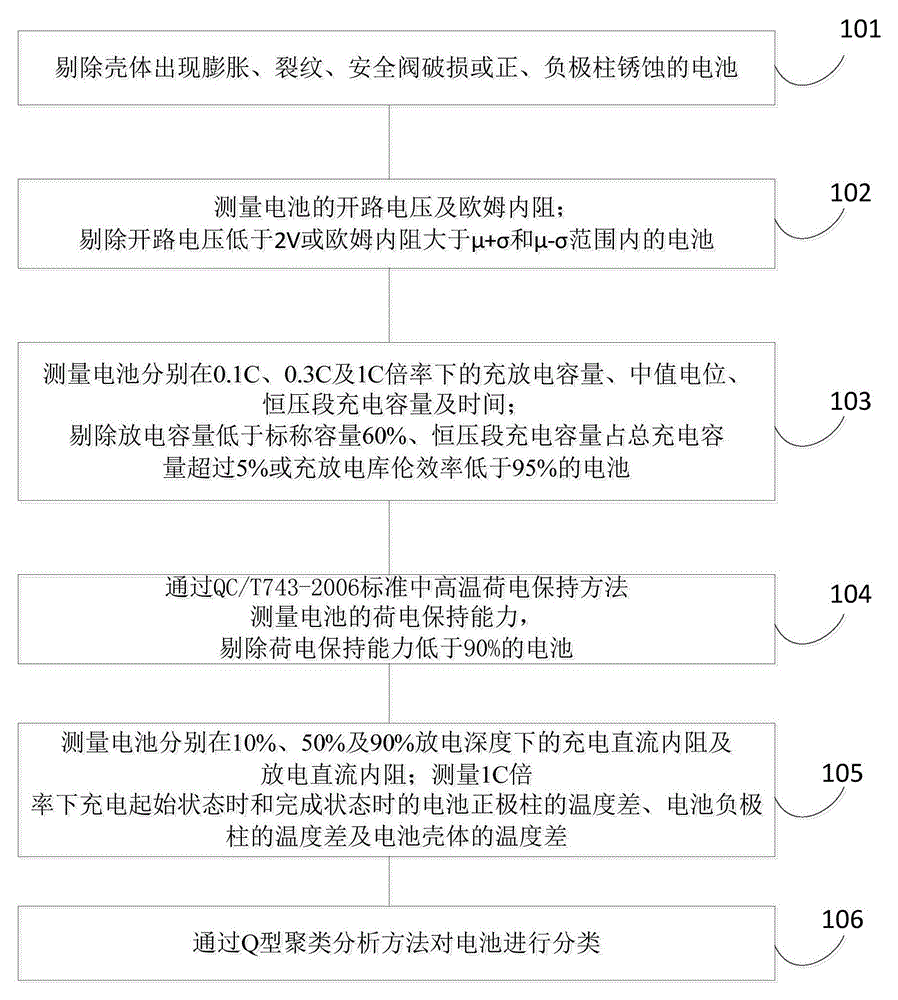

[0031] The screening method of the lithium iron phosphate single battery of a preferred embodiment of the present invention utilizes 60 lithium iron phosphate single batteries returned in the electric vehicle to carry out screening, such as figure 1 As shown, the screening method comprises the steps of:

[0032] Step 101 , rejecting lithium iron phosphate single cells that meet the following conditions: cells with swollen or cracked shells, cells with damaged safety valves, and cells with corroded positive poles or negative poles. The expansion of the shell of the removed battery, the degree of corrosion of the positive pole and the negative pole can be judged by the operator according to the actual situation.

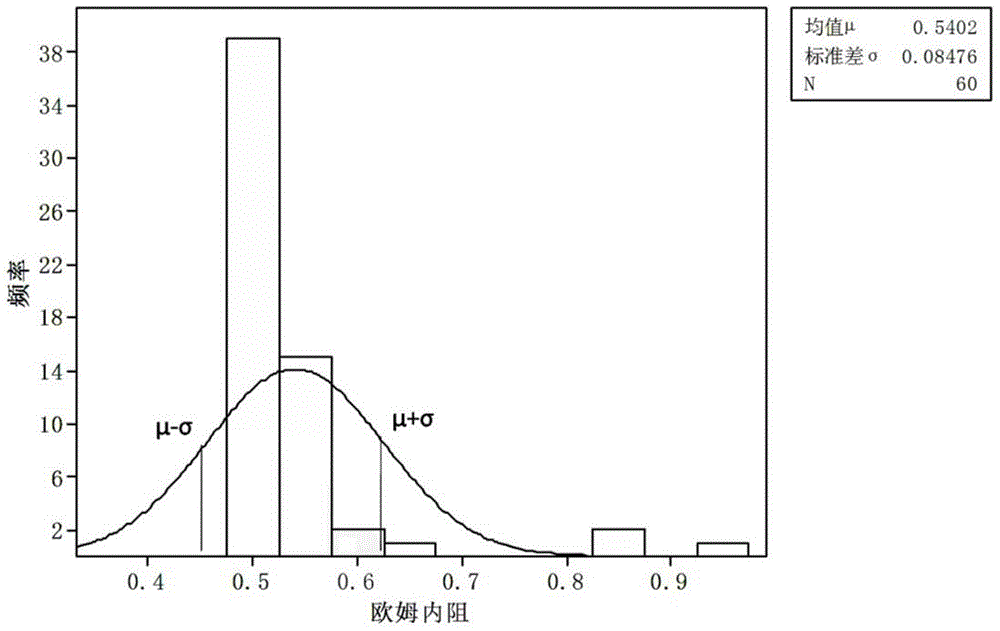

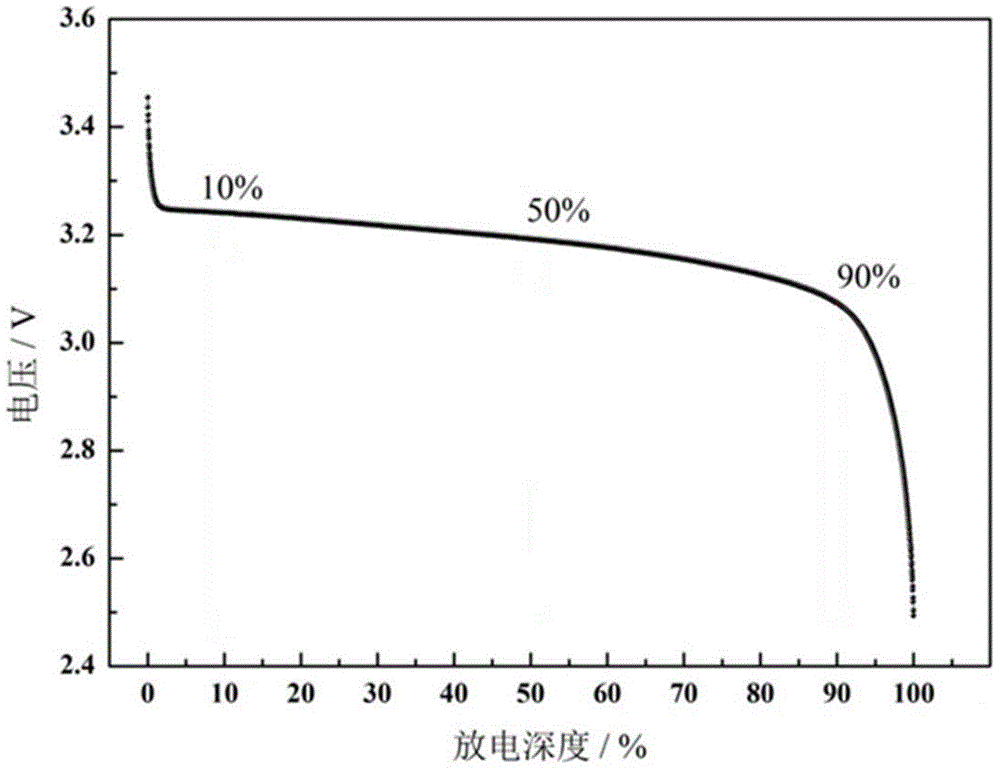

[0033] Step 102. Use an internal resistance meter to measure the open circuit voltage and ohmic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com