Fodder feeding device

A technology of feeding device and feed, applied in animal feeding device, application, poultry industry and other directions, can solve the problems of high working pressure of motor, high cost, and difficult transformation, and achieve small installation site limitations and low transformation cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

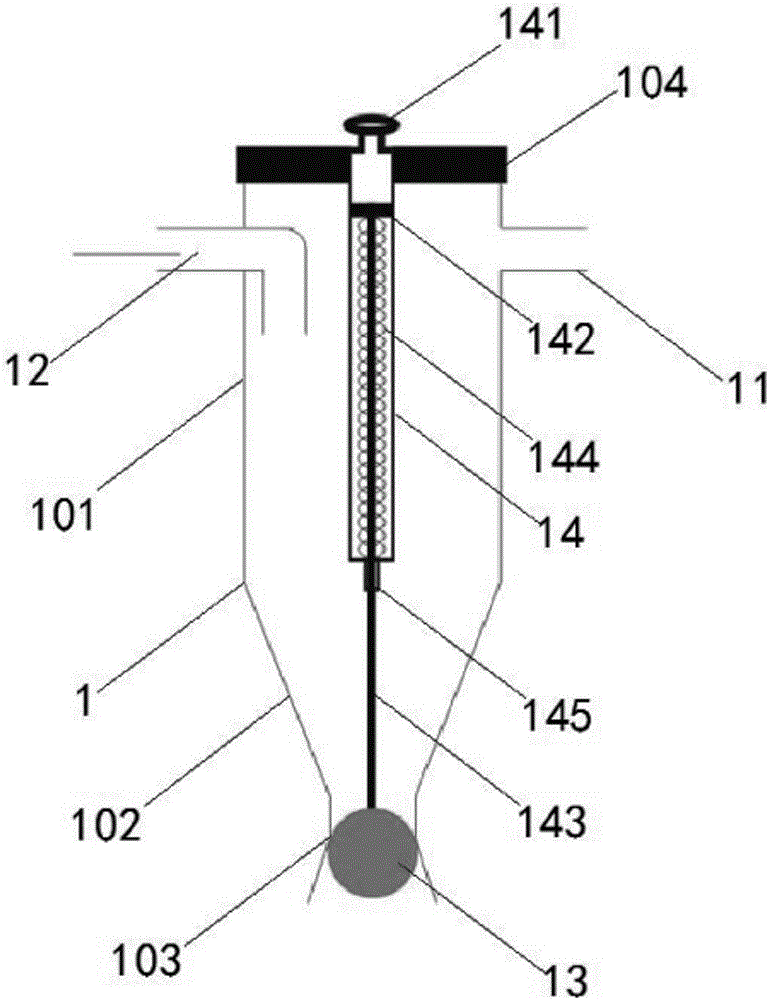

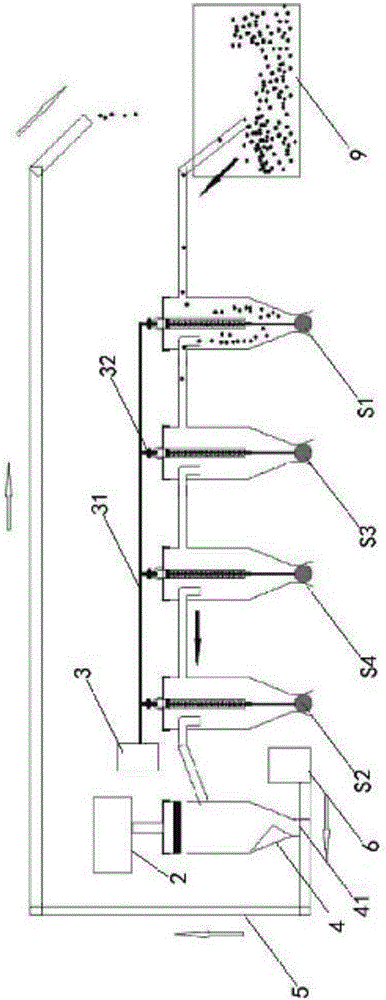

[0035] Embodiment 1: refer to Figure 1-4 , a feed delivery device comprising

[0036] Structure 1:

[0037] At least one intermediate group of series-connectable suction hoppers is connected in series between the initial group of serial-connectable suction hoppers S1 and the end-group of serial-connectable suction hoppers S2, and the feed pipe and silo 9 of the initial group of serial-connectable suction hoppers S1 Connection, the discharge pipe of the terminal group can be connected in series with the suction hopper S2 to the suction device 2.

[0038] The initial group of tandem suction hoppers, the middle group of tandem suction hoppers, and the end group of tandem suction hoppers respectively include a sealed hopper main body 1 for accommodating feed, a feed pipe 11 arranged on the hopper main body 1, a row The feed pipe 12 , the discharge device, the feed pipe 11 and the discharge pipe 12 are arranged near the top of the hopper main body 1 .

[0039] The feeding pipe ...

Embodiment 2

[0040] Embodiment 2: On the basis of Embodiment 1, the first intermediate group of serial suction hoppers S3 and the second intermediate group Tandem suction hopper S4.

[0041] The discharge pipe of the initial series-connectable suction hopper S1 is connected to the feed pipe of the first intermediate series-connectable suction hopper S3, and the discharge pipe of the first intermediate series-connectable suction hopper S3 is connected to the second intermediate group. The feed pipe of the hopper S4, the discharge pipe of the tandem suction hopper S4 of the second middle group is connected to the feed pipe of the adjacent group of tandem suction hoppers S2 in the direction of the end.

[0042] The negative pressure of the air extraction device 2 further makes the air flow and feed flow from the initial group of serial suction hoppers S1, the first middle group of serial suction hoppers S3, the second middle group of serial suction hoppers S4, and the end group Tandem suctio...

Embodiment 3

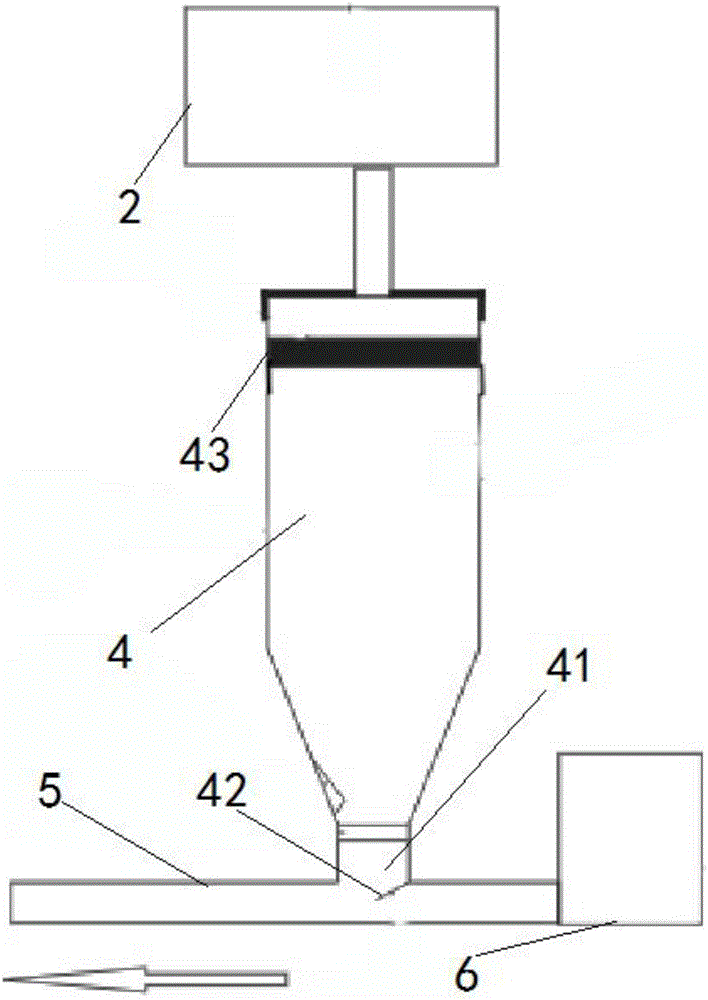

[0058] Embodiment 3: On the basis of Example 1, in order to further recycle the feed, a collection barrel 4 is arranged between the terminal group of the serial suction hopper S2 and the air extraction device 2, and the discharge of the terminal group of the serial suction hopper S2 The tube communicates with the collecting bucket 4, and the air extraction device 2 is connected with the collecting bucket 4 through the negative pressure output pipe.

[0059] A feed filter screen 43 is arranged at the connection between the air extraction device 2 and the collecting barrel 4, and the feed filter screen 43 can effectively prevent feed from entering the air extraction device 2 and cause the failure of the air extraction device 2.

[0060] The bottom of the collection barrel 4 is provided with a gravity induction power-off switch or a pressure-sensing power-off switch connected in series on the power supply circuit of the air extraction device 2. Enter into the collection bucket 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com