AMOLED display manufacturing method and AMOLED display

A manufacturing method and display technology, which can be used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., and can solve the problems of large limitations of AMOLED displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

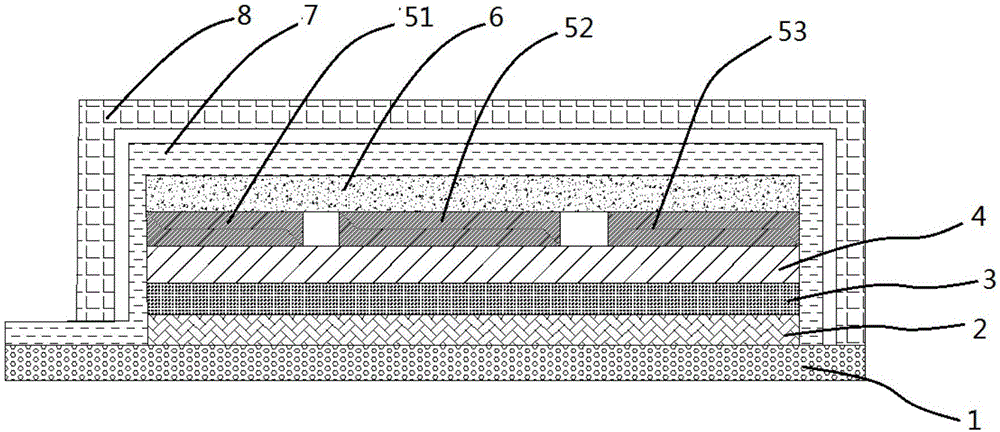

[0042] like figure 1 As shown, the structure of the AMOLED display provided by the method described in this application is the same as that of the existing AMOLED display, and the AMOLED display includes a second substrate 1, an AMOLED light-emitting area and an encapsulation layer 8, and the AMOLED light-emitting area is arranged on the second substrate 1, the encapsulation layer 8 is arranged on the top and around the AMOLED light-emitting area to encapsulate the AMOLED light-emitting area.

[0043] The AMOLED light-emitting area includes cathode 7, electron layer 6, light-emitting layers 51 / 52 / 53, hole layer 4, anode 3 and thin film transistor 2 (TFT) arranged in sequence from top to bottom. The thin film transistor 2 is attached to the second substrate 1 .

[0044] Wherein, the second substrate 1 is generally made of a transparent polymer material, such as polyimide (PI), as a substrate of an AMOLED display. The TFT 2 includes a gate, a gate insulating layer, an active l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com