The construction method of the integral top penetration of the water wall of the waste heat boiler for waste incineration power generation

A waste heat boiler, waste incineration technology, applied in the combustion method, boiler water pipe, combustion chamber and other directions, can solve the problems of first storage near the installation location, the welding quality cannot be guaranteed, and the working surface cannot be unfolded, etc. The effect of empty pipe row group on the number of welding, improving work efficiency and engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated by specific examples below.

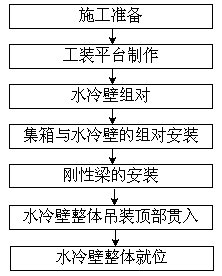

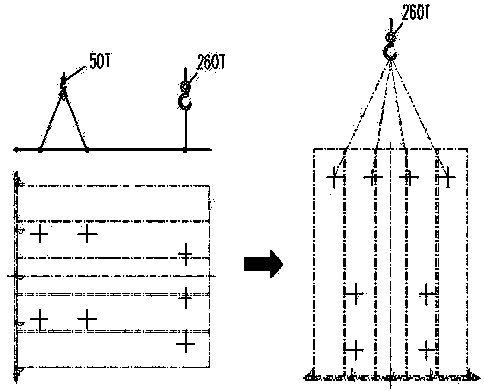

[0030] A construction method for penetrating the integral top of the water wall of a waste incineration power generation waste heat boiler, comprising

[0031] Step 1. Production of water wall tooling platform:

[0032] Two I-beams are used to make 4 sets of water walls at the same time. The height of the tooling platform from the ground is at least 1 meter. Each leg of the tooling platform is supported on a concrete pier or concrete pavement to prevent the platform from sinking and deforming. Adjust the elevation of the tooling platform to ensure levelness;

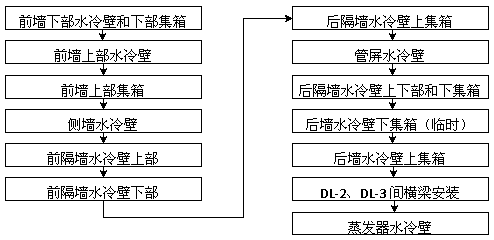

[0033] Step 2. Assemble the water wall in sections on the ground:

[0034] The limit device is welded on the water wall tooling platform, and the limit device is 4 meters apart for the assembly and adjustment of the water wall; when the water wall is assembled, the length, width and diagonal dimensions are mainly adjusted to ensure the geometric siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com