Anti-erosion and friction-resistant film for fan blades of aeto-turbofan engine and preparation method of anti-erosion and friction-resistant film

A turbofan engine and fan blade technology, applied in the direction of engine function, machine/engine, liquid fuel engine, etc., to achieve the effect of improving anti-erosion performance, high hardness, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

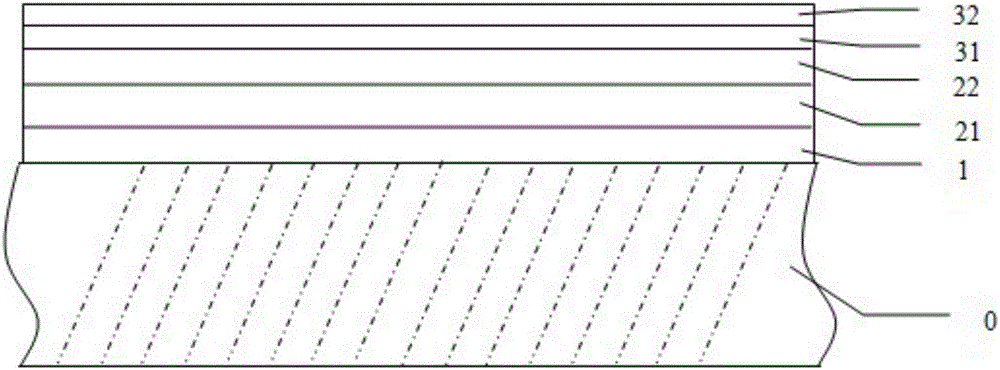

[0030] An anti-erosion and friction-resistant film for fan blades of aviation turbofan engines according to the present invention, the anti-erosion and friction-resistant films for fan blades of aviation turbofan engines are blade base 0 and transition layer 1 from inside to outside , anti-friction film layer and anti-erosion film layer; the anti-erosion and anti-friction film used for fan blades of aviation turbofan engines is deposited sequentially from the inside to the outside of the blade base.

[0031] The blade base 0 is a titanium alloy; the transition layer 1 is a metal titanium or metal chromium layer; The etch film layers are successively a chromium aluminum titanium nitride layer 31 and a chromium titanium nitride layer 32 from the inside to the outside.

[0032] The thickness of the metallic titanium or metallic chromium layer of described transition layer is 15nm, improves film adhesion,

[0033] The thickness of the titanium nitride layer 21 is 0.8 μm, and the ...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is:

[0045] A kind of anti-erosion and anti-friction film for the fan blade of aviation turbofan engine of the present invention, the thickness of the metal titanium or metal chromium layer of described transition layer is 30nm, improves film adhesion,

[0046] The thickness of the titanium nitride layer 21 is 1.2 μm, and the thickness of the aluminum titanium nitride layer 22 is 1.0 μm.

[0047] The thickness of the chromium aluminum titanium nitride layer 31 is 1.8 μm, and the thickness of the chromium titanium nitride layer 32 is 2.0 μm.

[0048] The nitrogen content of the titanium nitride layer 21 increases gradually from the inside to the outside; the nitrogen content and titanium content of the aluminum titanium nitride layer 22 gradually decrease from the inside to the outside, and the aluminum content gradually increases; the nitrogen content of the chromium aluminum titanium nitride layer 31 increases from ...

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is:

[0059] A kind of anti-erosion and anti-friction film for the fan blade of aviation turbofan engine of the present invention, the thickness of the metal titanium or metal chromium layer of described transition layer is 40nm, improves film adhesion,

[0060] The thickness of the titanium nitride layer 21 is 1.5 μm, and the thickness of the aluminum titanium nitride layer 22 is 1.2 μm.

[0061] The thickness of the chromium aluminum titanium nitride layer 31 is 1.6 μm, and the thickness of the chromium titanium nitride layer 32 is 1.8 μm.

[0062] The preparation method of the anti-erosion and anti-friction film for the fan blade of aviation turbofan engine according to the present invention comprises the following steps:

[0063] (1) The multi-arc ion plating method is adopted, the coating equipment is in a clean space, the cleanliness is within 100,000 grades, the cooling water temperature is 26°C, and the humid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com