Hot melt adhesive powder

A technology of front top and composite nucleating agent, which is applied in the field of front top glue, can solve the problems of high price, achieve the effects of low cost, reduced processing cost, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

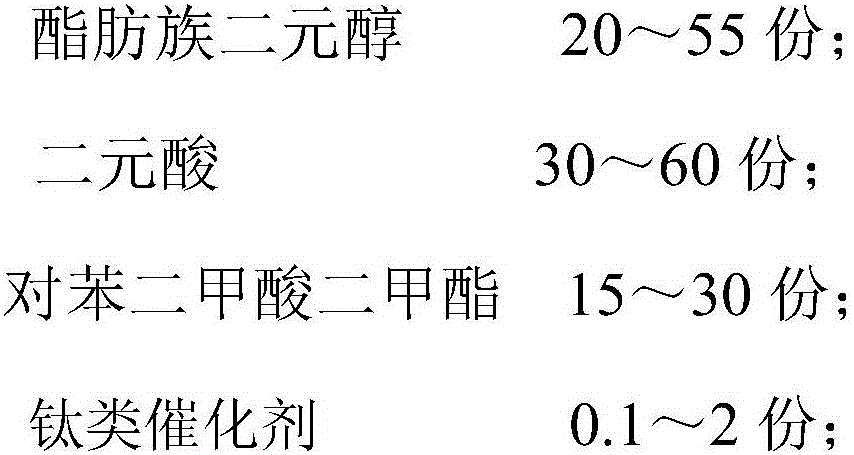

[0022] Front side glue, comprises each component of following parts by weight:

[0023]

[0024]

[0025] Wherein, the composite nucleating agent is a silicon dioxide ultrafine powder-sodium benzoate composite nucleating agent.

[0026] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, referred to as antioxidant 1010.

Embodiment 2

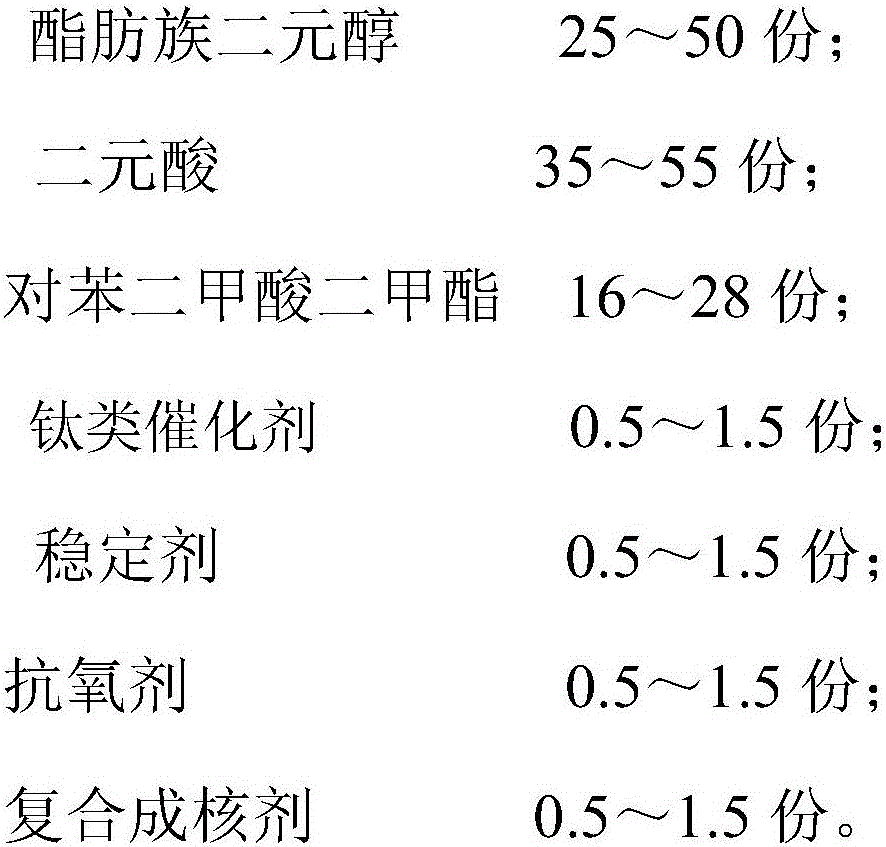

[0028] Front side glue, comprises each component of following parts by weight:

[0029]

[0030] Wherein, the composite nucleating agent is a silicon dioxide ultrafine powder-sodium benzoate composite nucleating agent.

Embodiment 3

[0032] Front side glue, comprises each component of following parts by weight:

[0033]

[0034]

[0035] Wherein, the composite nucleating agent is a silicon dioxide ultrafine powder-sodium benzoate composite nucleating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com