Automatic control device for water for bridge pier column maintenance

A technology of automatic control device and pier column, which is applied in the field of bridge construction engineering, can solve the problems of unsustainable water supply and maintenance, high pier column and not easy to sprinkle water, etc., and achieves the effect of flexible installation and use, low cost and guarantee of continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

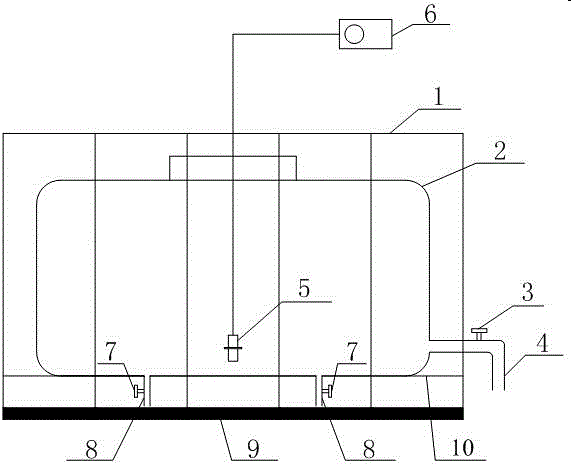

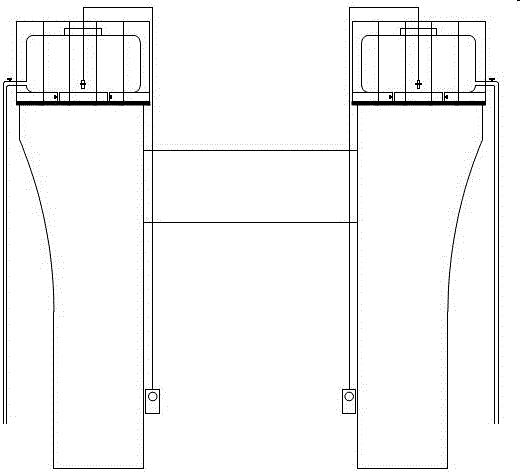

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises water tank 2, and water tank 2 is fixed in steel bar cage 1, and steel bar cage 1 upper opening, surroundings and bottom are welded with steel bars, and a layer of steel bar support 10 is welded at 10 cm above the bottom, and water tank 2 is placed on this steel bar support 10, this The reinforcement cage 1 of the embodiment is welded by threaded steel bars with a diameter of 24 mm.

[0015] A sensor probe 5 is installed in the water tank 2, the sensor probe 5 is connected with the alarm 6, the sensor probe 5 enters the water in the water tank 2, and when the water level in the water tank 2 drops to the point where the sensor probe 5 leaves the water surface, the alarm 6 will automatically alarm, When the sensor probe 5 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com