Nanometer magnesium oxide with dark-room sterilization and sewage degradation performance and method for preparing nanometer magnesium oxide

A technology for nano-magnesia and sewage degradation, which is applied in the field of nano-magnesia and its preparation, sterilization and sewage degradation performance materials, can solve the problems of high product price and complex synthesis process, and achieve low price, simple synthesis process and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix magnesium nitrate hexahydrate, diethylamine hydrochloride and urea with a molar ratio of 1.0:0.5:0.2, heat to 150 °C, the mixture melts into a liquid, and continues to heat until it is completely burned to produce a solid powder, which is cooled and ground. After that, a white powder was obtained.

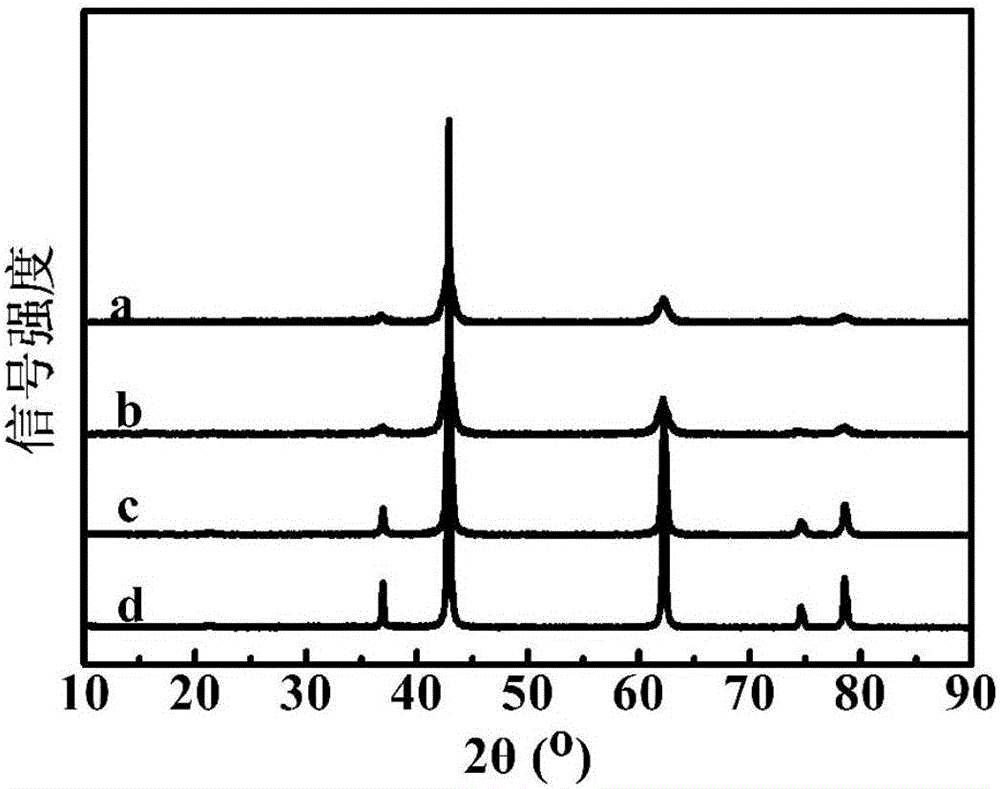

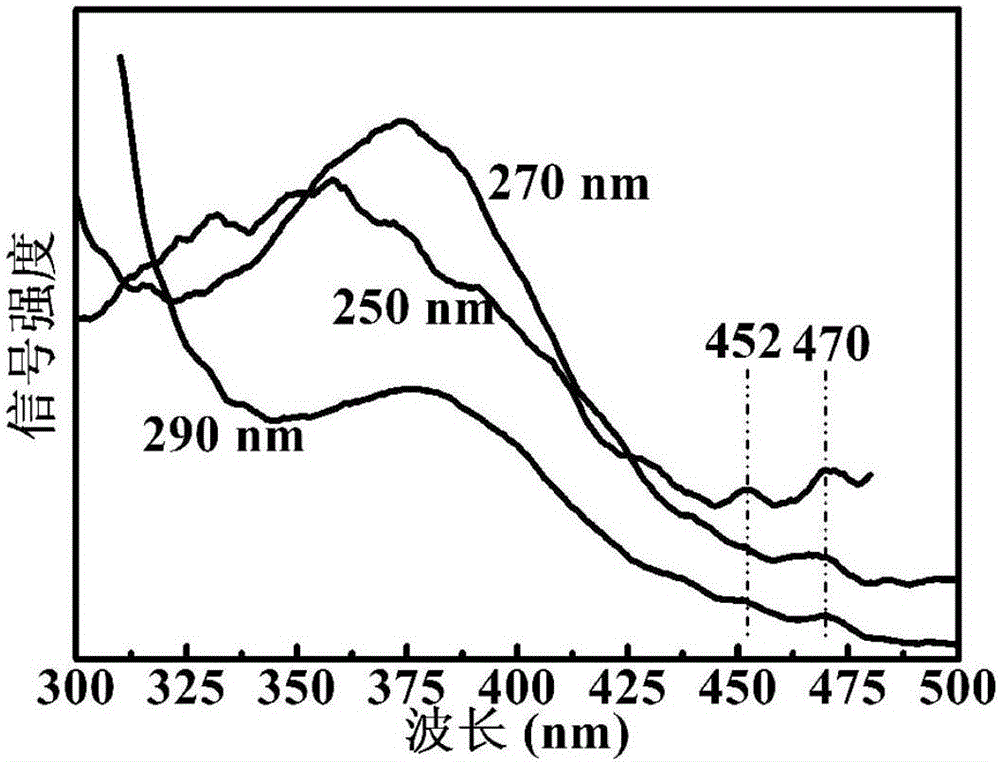

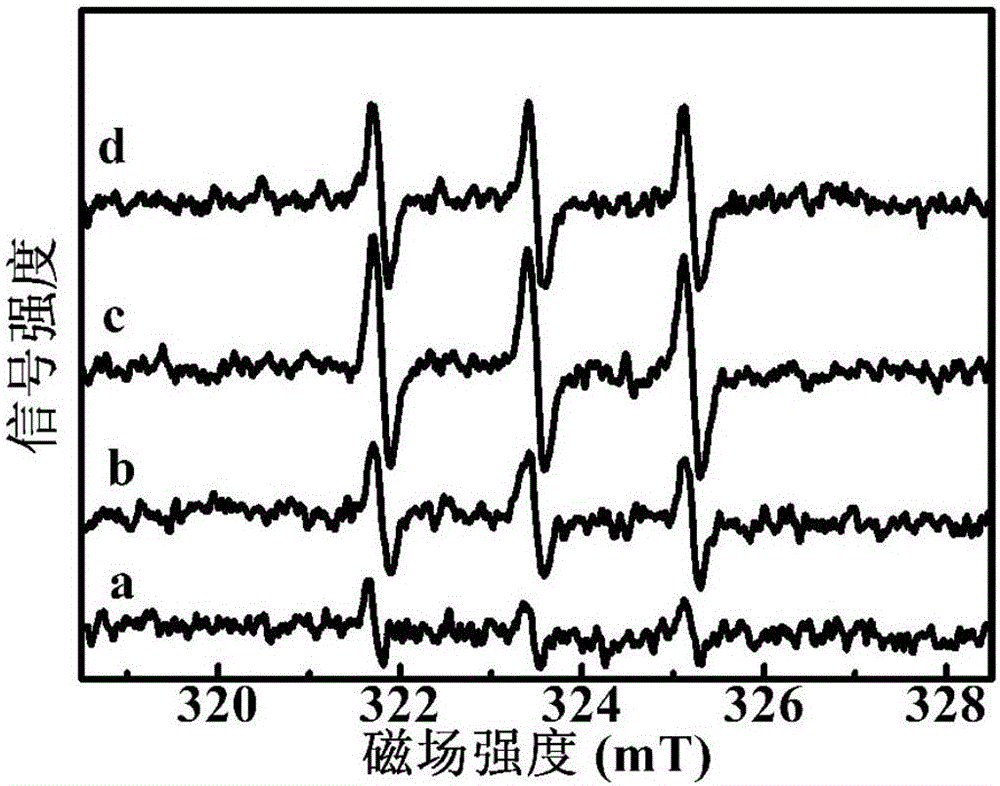

[0030] The obtained white powders were tested by XRD, PL, ESR and dark current, and the spectra are shown in figure 1 a. figure 2 , image 3 a and Figure 4 . The test results show that the purity of the synthesized sample in this example is relatively high, and its particle size is calculated to be about 10 nm according to Scherrer's formula. When the excitation wavelength is 250-290 nm, the synthesized samples in this example have weak visible light emission peaks at 452 nm and 470 nm, respectively, indicating that there may be oxygen vacancies on their surfaces. image 3 The result of a shows that singlet oxygen species can be directly generated on the surface o...

Embodiment 2

[0034] Repeat the operation steps of embodiment 1, the difference is that the mol ratio of magnesium nitrate hexahydrate, diethylamine hydrochloride, urea in the initial mixture is 1.0:1.0:0.5, and the control heating temperature is 200 ° C, and finally obtains a kind of after burning. White powder.

[0035] The above white powder was tested by XRD, ESR, Raman, TEM and TEMHR, and the spectra were shown in figure 1 b. image 3 b. Figure 5 and Image 6 . figure 1 b shows that the synthetic sample of this example is pure magnesium oxide, and the particle size is about 20 nm; image 3 b indicates that singlet oxygen is generated in the synthesized samples in this example, which indirectly indicates the existence of surface oxygen vacancies. Figure 5 The Raman signals (5b) of molecular oxygen on commercial magnesium oxide (5a) and the synthetic samples of this example at different temperatures are shown. Figure 5 b shows that the Raman signal of superoxide anion species ca...

Embodiment 3

[0040] Repeat the operation steps of embodiment 1, the difference is that the mol ratio of magnesium nitrate hexahydrate, diethylamine hydrochloride, urea in the starting mixture is 1.0:1.5:1.0, and the control heating temperature is 250 ° C, and a white color is obtained after burning. powder.

[0041] figure 1 c shows that the synthetic sample in this example is pure magnesium oxide, and the particle size is about 30 nm; image 3 c shows that singlet oxygen is generated in the synthesized sample in this example, which indirectly indicates the existence of surface oxygen vacancies. Figure 10 The results indicated that singlet oxygen, hydroxyl radicals and dissolved oxygen had certain effects on the darkroom degradation behavior of methyl violet azo molecules.

[0042] The test of catalytic degradation of methyl violet and sterilization in the dark room was carried out according to the method of Example 1. The results showed that the degradation rate of methyl violet for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com