Anthracene oil hydrogenating circulating hydrogen recycling and purifying device

A technology of hydrogen circulation and anthracene oil, which is applied in the directions of hydrogen separation, liquid contact hydrogen separation, and dispersed particle separation, etc., can solve the problems of poor economy of hydrogen combustion in anthracene oil hydrogenation cycle, pollution of combustion gas emission, etc., and achieve saving of raw materials The effect of increasing the amount of hydrogen, increasing the recycling rate, and increasing the purity of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

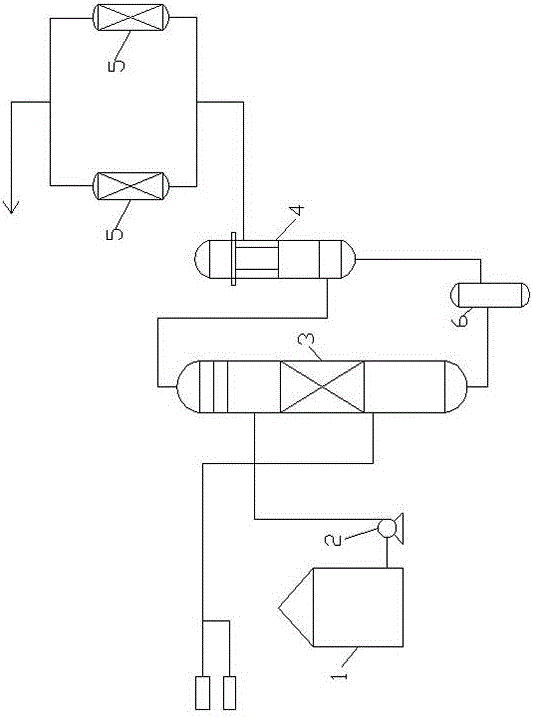

[0012] As shown in the figure, an anthracene oil hydrogenation cycle hydrogen recovery and purification device includes a desulfurization mechanism and a pressure swing adsorption mechanism. The desulfurization mechanism consists of a desulfurization solvent tank 1, a solvent circulation pump 2 and a desulfurization tower 3. The pump 2 is connected with the upper part of the desulfurization tower 3, the inlet of the lower part of the desulfurization tower 3 is connected with the anthracene oil discharge hydrogen pipeline and the fluidized bed discharge hydrogen pipeline, the bottom outlet of the desulfurization tower 3 is connected with the filter 6, and the pressure swing adsorption mechanism is composed of cryocooler 4 and two Two parallel pressure swing adsorption tanks 5 are formed, the desulfurization tower 3 top gas outlet is connected with cryocooler 4, the outlet of cryocooler 4 is connected with parallel pressure swing adsorption tank 5, and the bottom outlet of cryocoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com