3D printing method for continuous fibre-reinforced thermoplastic resin matrix composite material, and printing head

A technology for strengthening thermoplastic and thermoplastic resins, applied in the direction of additive processing, processing and manufacturing, etc., can solve the problems of effective impregnation and molding speed of connecting fibers, low comprehensive performance of molded parts, and relatively large component size restrictions, so as to improve the interlayer and The effect of interface bonding performance, improving surface quality, and increasing printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

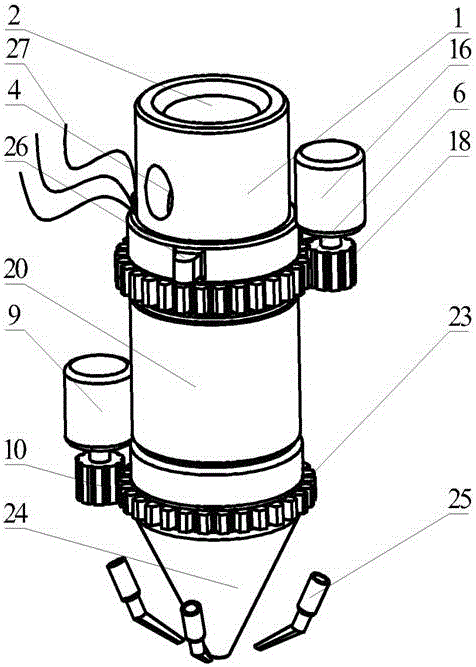

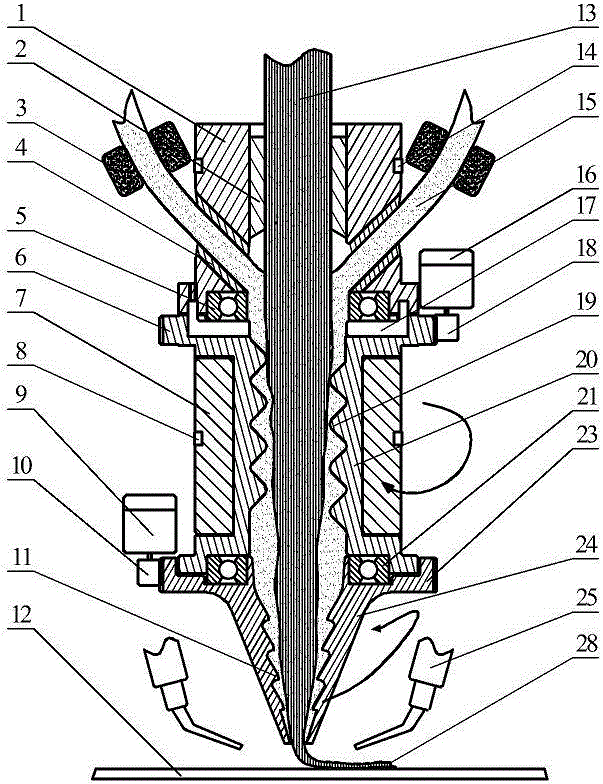

[0028] Such as Figure 1-2 shown.

[0029] A 3D printing method for continuous fiber-reinforced thermoplastic resin-based composite materials. First, the connecting fiber bundles are pretreated to enhance the bonding force between the connecting fiber bundles and the resin matrix. Secondly, the pretreated continuous fiber bundles are mixed with the thermoplastic resin simultaneously. Pass into the melting chamber of the rotary blending 3D printing head; thirdly, make the melting chamber rotate around its central axis, and the extrusion head connected to the melting chamber can also rotate around the central axis, controlling the rotation direction of the extrusion head and the placement of the melting chamber The direction is opposite; Fourth, a stirring gear ring is set on the inner side of the melting chamber and the extrusion head, and the fiber bundle and the molten thermoplastic resin are uniformly blended under the stirring action of the two-stage counter-rotating helica...

Embodiment 2

[0044] Such as Figure 1-2 shown.

[0045] A rotary blending 3D printing head for forming continuous fiber-reinforced thermoplastic resin-based composite materials, which includes a three-way feeding chamber 1, a melting chamber 20 and an extrusion head 24, the three-way feeding chamber 1 is fixed on the upper bracket, and the three-way Both sides of feeding cavity 1 are obliquely provided with thermoplastic consumables 15 feeding pipes and feeding wheels 3, and the center of tee feeding chamber 1 is longitudinally provided with fiber tow 13 feeding pipes; tee feeding chamber 1 uses hollow slip ring 17 and first The sealed bearing 5 is connected with the melting chamber 20, and the outer wall of the melting chamber 20 is nested with a tubular heating jacket 7, and the electrodes of the tubular heating pipe are electrically connected with the pins of the hollow slip ring 17; Temperature sensors 14, 8 are installed, and the wires of the temperature sensor outside the melting ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com