Double wringing water removal method for tire rubber component

A rubber and tire technology, applied in the field of rubber tire production, can solve the problems of sponge damage, extrusion treatment, small contact area, etc., and achieve the effect of reducing industrial accidents, prolonging service life, and ensuring water absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

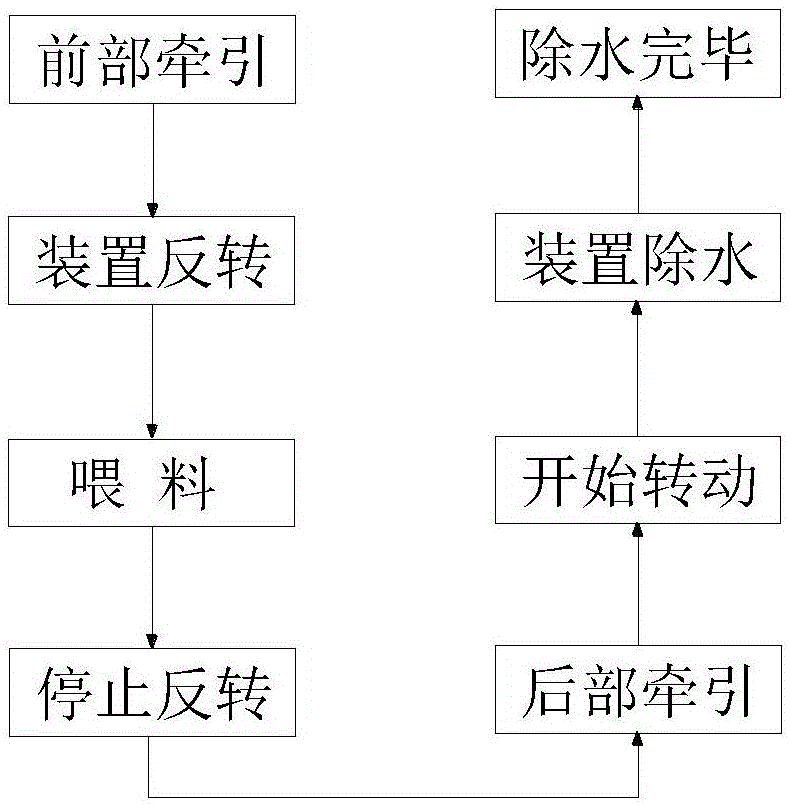

[0027] The technical process of the double-squeezing water-removing method for tire rubber components related to the present embodiment comprises the following steps:

[0028] (1): front traction: pull the tire rubber assembly 9 from other conveying devices in front of the double squeeze water removal device to the material channel inlet 101 of the double squeeze water remover device;

[0029] (2): device reversal: the drive device 601 is set to reverse by the drive control device 602, and the drive device 601 is started;

[0030] (3): Feeding: dry the water at the end of the tire rubber assembly 9, insert the tire rubber assembly 9 into the middle gap formed by the crawler-shaped upper sponge 701 and the crawler-shaped lower sponge 702, and make the tire rubber assembly 9 follow the The crawler-shaped sponge 701 and the crawler-shaped lower sponge 702 move to the material channel outlet 102;

[0031] (4): stop reversing: turn off the driving device 601 through the driving co...

Embodiment 2

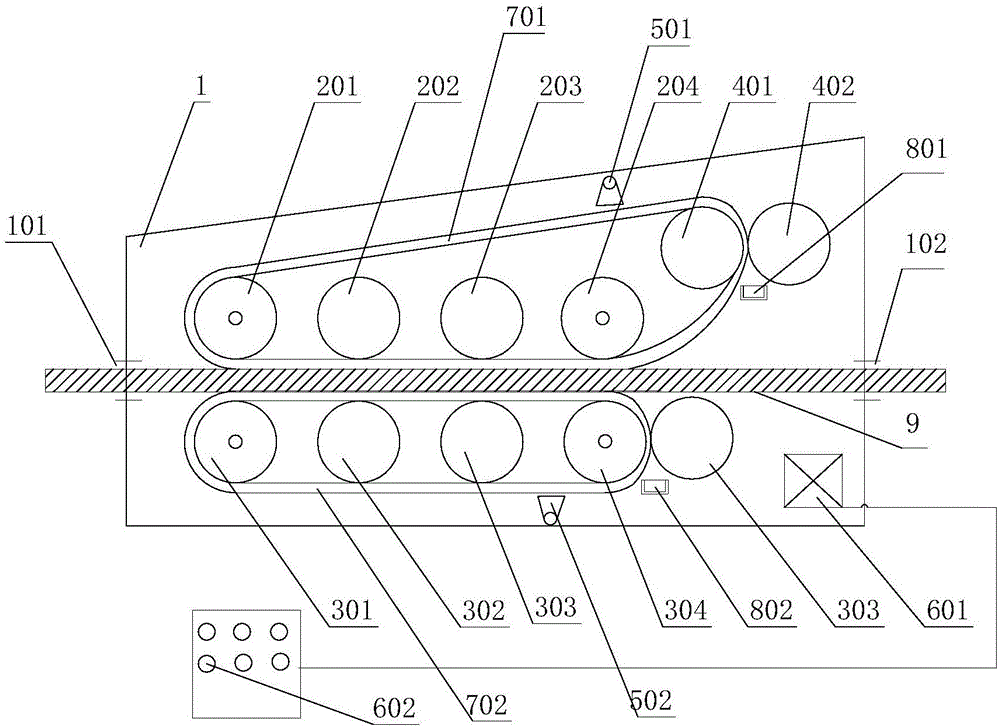

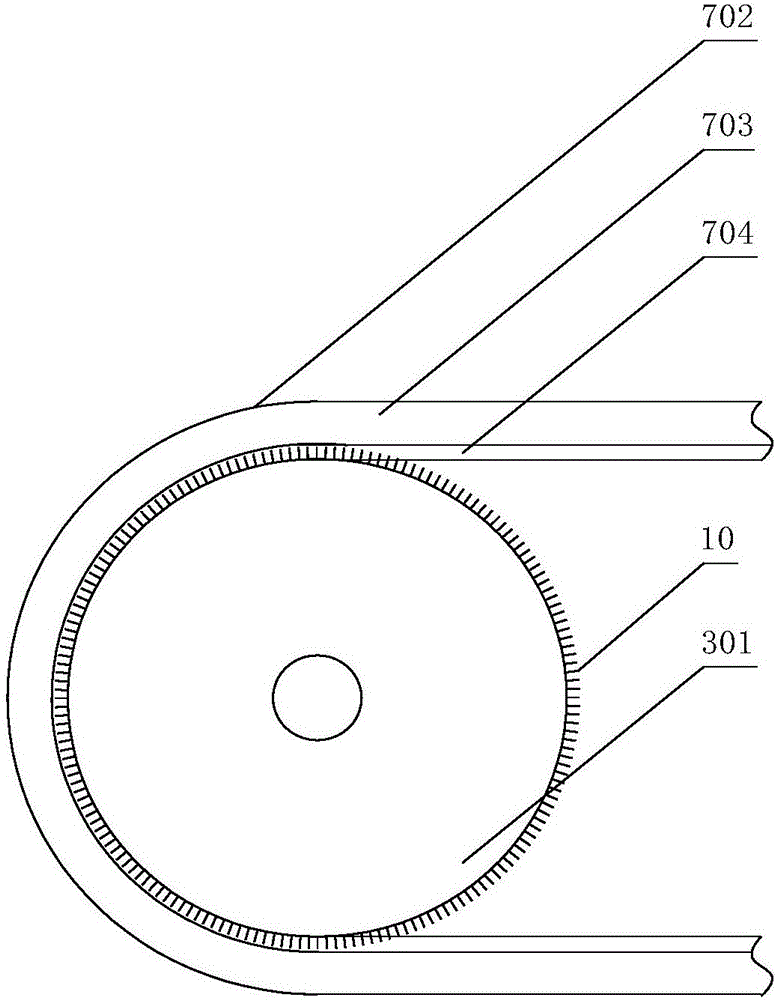

[0040] The double-squeezing and water-removing device for tire rubber components involved in this embodiment has the same main structure as that of Embodiment 1, except that the first upper supporting roller 201, the first upper squeezing roller 401, the first The surface of the lower supporting roller 301 and the fourth lower supporting roller 304 is distributed with spikes 10, the second upper supporting roller 202, the third upper supporting roller 203, the fourth upper supporting roller 204, the second lower supporting roller 302, the third lower supporting roller The surfaces of the supporting roller 303, the second upper squeezing roller 402, and the lower squeezing roller 403 are smooth. The track-shaped upper sponge 701 and the track-shaped lower sponge 702 all include a sponge layer 703 and a cord layer 704. The thickness of the cord layer 704 is 1.1 times the length of the spike 10. The cord layer 704 is connected to the first upper support roller 201 and the second u...

Embodiment 3

[0042] The double squeeze water removal device for tire rubber components involved in this embodiment has the same main structure as that of Embodiment 1, the difference is that the upper water tank 801 is a strip-shaped long groove, and the upper water tank 801 is The long side is parallel to the axis of the first upper water squeezing roller 401, the length of the long side of the upper water tank 801 is greater than the width of the track-shaped sponge 701, and the upper water tank 801 bottom is connected with an upper drain pipe 803. This design of timely squeezing and drying the track-shaped sponge 701 that has absorbed moisture can keep the track-shaped sponge 701 in a relatively dry state and maintain high water absorption and water removal efficiency. The lower receiving water tank 802 is located below the gap between the fourth lower support roller 304 and the lower squeezing water roller 403; the lower receiving water tank 802 is a strip-shaped long groove, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com