Resin fiber abrasive block and preparation method thereof

A resin fiber and grinding block technology, which is applied in the direction of grinding/polishing equipment, abrasive materials, grinding devices, etc., can solve the problems of rough processing surface, easy to produce grinding marks, and lack of profiling ability, etc., to achieve soft luster and smooth processing fine surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

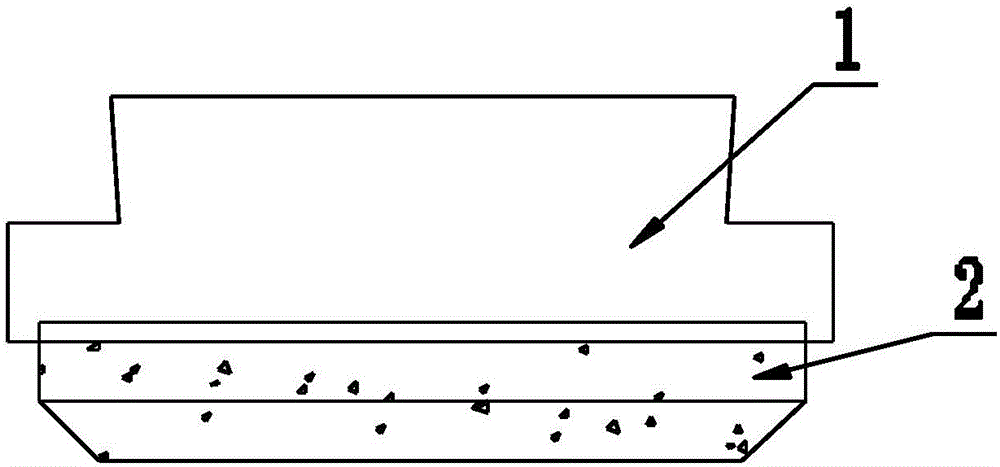

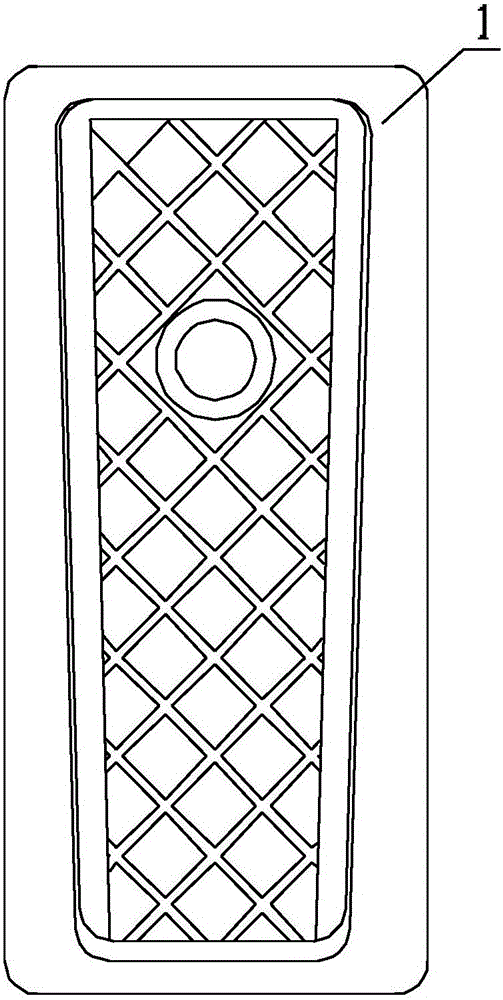

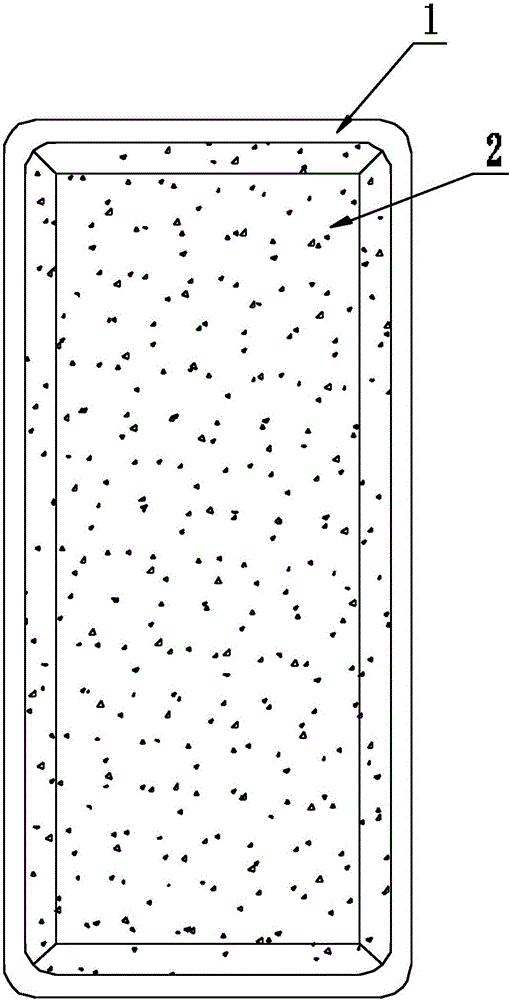

[0027] refer to Figure 1-3 , a resin fiber grinding block, consisting of a deck 1 and a resin fiber grinding block 2 bonded in the deck 1, the resin fiber grinding block includes nylon cotton and the fiber adsorbed in the nylon cotton Mixed solution: The mixed solution includes the following raw materials in parts by weight: 100 parts of binder, 80 parts of abrasive, and 8 parts of filler. The volume ratio of the nylon cotton to the mixed solution is 3:1.

[0028] The adhesive comprises the following raw materials in parts by weight: 80 parts of resin, 10 parts of curing agent and 10 parts of diluent.

[0029] The resin is epoxy resin. The abrasive is silicon carbide. The filler is chromium oxide green.

[0030] A preparation method of resin fiber grinding block, comprising the following steps:

[0031] 1) After uniformly mixing the binder, abrasive and filler according to the formula ratio, a mixed solution is obtained,

[0032] 2) adding the mixed solution into the ny...

Embodiment 2

[0037] A resin fiber grinding block, which is composed of a deck and a resin fiber grinding block bonded in the deck, the resin fiber grinding block includes nylon cotton and a mixed solution adsorbed in the nylon cotton; The mixed solution includes the following raw materials in parts by weight: 50 parts of adhesive, 40 parts of abrasive, and 5 parts of filler.

[0038] The adhesive includes the following raw materials in parts by weight: 40 parts of resin, 5 parts of curing agent and 5 parts of diluent. The resin is phenolic resin. The abrasive is diamond. The filler is polishing powder.

[0039] The preparation method of the resin fiber grinding block is the same as that in Example 1.

Embodiment 3

[0041] A resin fiber grinding block, which is composed of a deck and a resin fiber grinding block bonded in the deck, the resin fiber grinding block includes nylon cotton and a mixed solution adsorbed in the nylon cotton; The mixed solution includes the following raw materials in parts by weight: 150 parts of binder, 130 parts of abrasive, and 10 parts of filler.

[0042] The adhesive includes the following raw materials in parts by weight: 120 parts of resin, 15 parts of curing agent, and 15 parts of diluent. The resin is two kinds of epoxy resin and phenolic resin. The abrasive is white corundum. The filler is calcium carbonate.

[0043] The preparation method of the resin fiber grinding block is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com