Industrial robot for grinding and polishing propeller and grinding and polishing method

A technology of industrial robots and propellers, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding workpiece supports, etc., to achieve the effects of avoiding broken grinding heads, improving processing consistency, and avoiding abnormal collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

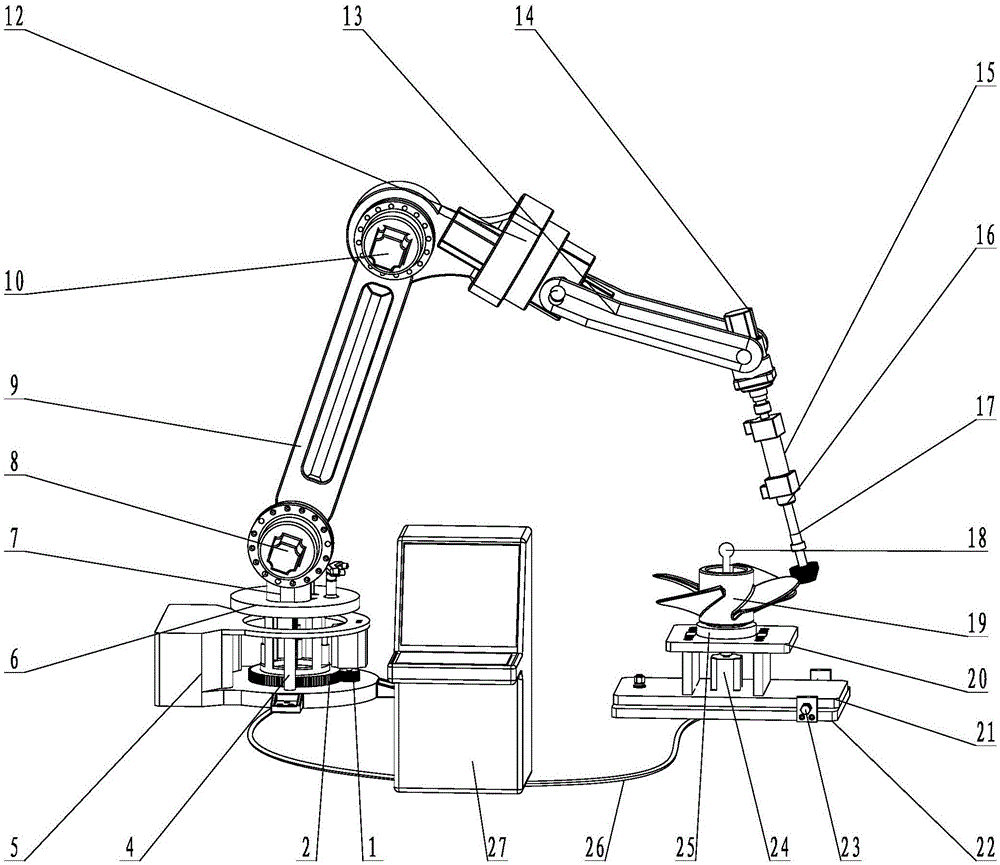

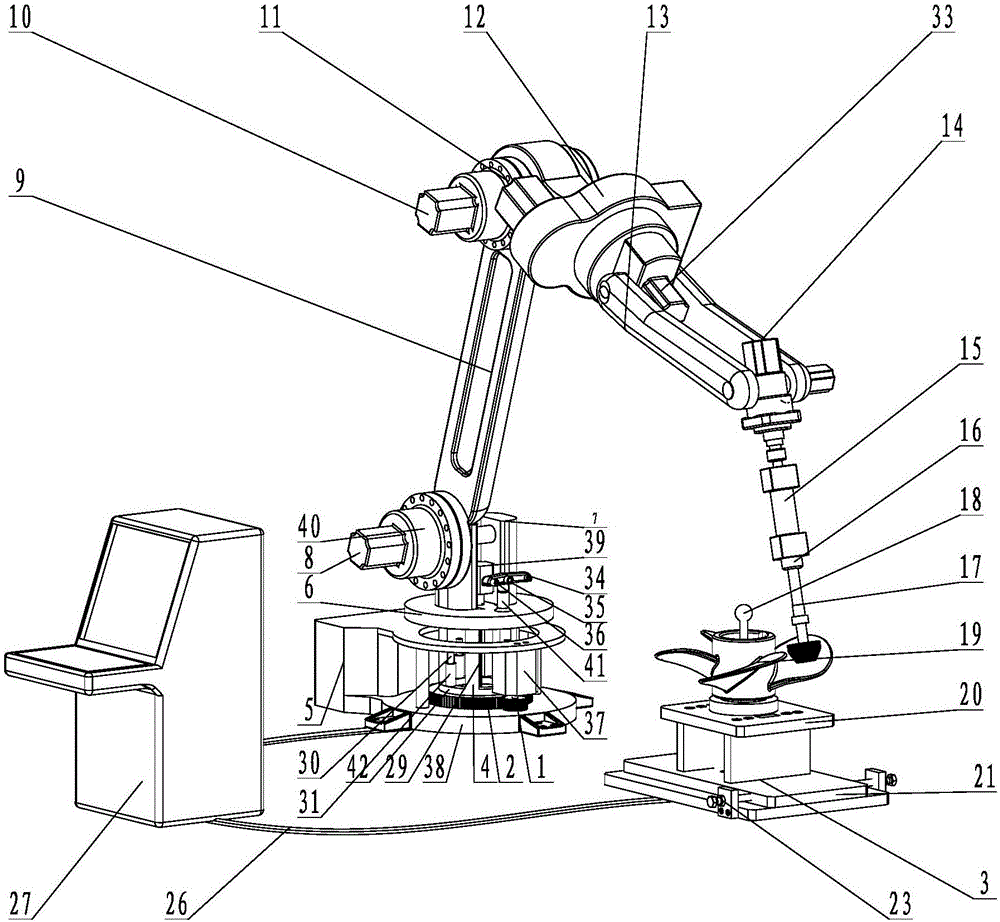

[0031] The present invention will be further described below in conjunction with specific drawings.

[0032] Such as Figure 1 to Figure 6 As shown: the propeller grinding and polishing industrial robot includes a small synchronous gear 1, a large synchronous gear 2, a rotary table 3, a support column 4, a distribution box 5, an upper support plate 6, a boom joint 7, and a boom rotation drive motor 8. Big arm 9, small arm rotary drive motor 10, small arm rotary gearbox 11, small arm rotary gearbox 12, small arm 13, actuator rotary drive motor 14, solenoid valve 15, pressure sensor 16, grinding head 17, Zero point coordinate positioning ball 18, propeller 19, tooling upper support plate 20, tooling positioning adjustment plate 21, tooling bottom plate 22, tooling positioning adjustment screw 23, propeller rotation drive motor 24, propeller rotation support ring 25, transmission line pipe 26, robot control Table 27, actuator rotation drive motor 28, lift screw 29, lift guide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com