Sheath-core composite photocatalytic fiber and method for preparing same

A technology of composite photocatalysis and composite light, which is applied in the field of photocatalytic materials, can solve the problems of poor photocatalytic degradation effect, and achieve the effects of excellent photocatalytic activity, high degradation rate, and excellent catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a skin-core composite photocatalytic fiber, comprising the following steps:

[0027] Put the skin-core composite polyester fiber into the composite photocatalyst solution, and perform padding treatment;

[0028] The fibers obtained by the padding treatment are subjected to the first heat treatment and the second heat treatment in sequence to obtain skin-core composite photocatalytic fibers.

[0029] In the invention, the sheath-core composite polyester fiber is dissolved in a composite photocatalyst solution and subjected to padding treatment. In the present invention, the core-skin composite polyester fiber includes core polyester and skin polyester; the melting point of the core polyester of the core-skin composite polyester fiber is preferably 250-270°C, more preferably 255-250°C. 265°C, most preferably 258-263°C; the melting point of the skin polyester is preferably 90-180°C, more preferably 100-160°C, most preferably 1...

Embodiment 1

[0072] Get 50g of low-melting point sheath-core composite polyester fiber, the conventional polyethylene terephthalate with a core melting point of 260°C, and the low-melting polyethylene terephthalate with a cortical melting point of 130°C, the mass ratio of the cortex 50%, short fiber shape, diameter 20μm, put it into 8g / L composite photocatalyst (TiO 2 90%, g-C 3 N 4 9.5%, unsubstituted iron phthalocyanine 0.5%) aqueous solution, the bath ratio is 1:30. Adsorb the composite photocatalyst onto the fiber by three dipping and three rolling methods, then put it in a 100°C oven for pre-baking for 30 minutes, continue to heat up to 135°C, bake for 30 minutes, wait for it to cool to room temperature, wash it with water to remove the insufficient adsorption on the fiber A firm catalyst can be dried in an oven at 60°C to obtain a skin-core composite photocatalytic fiber.

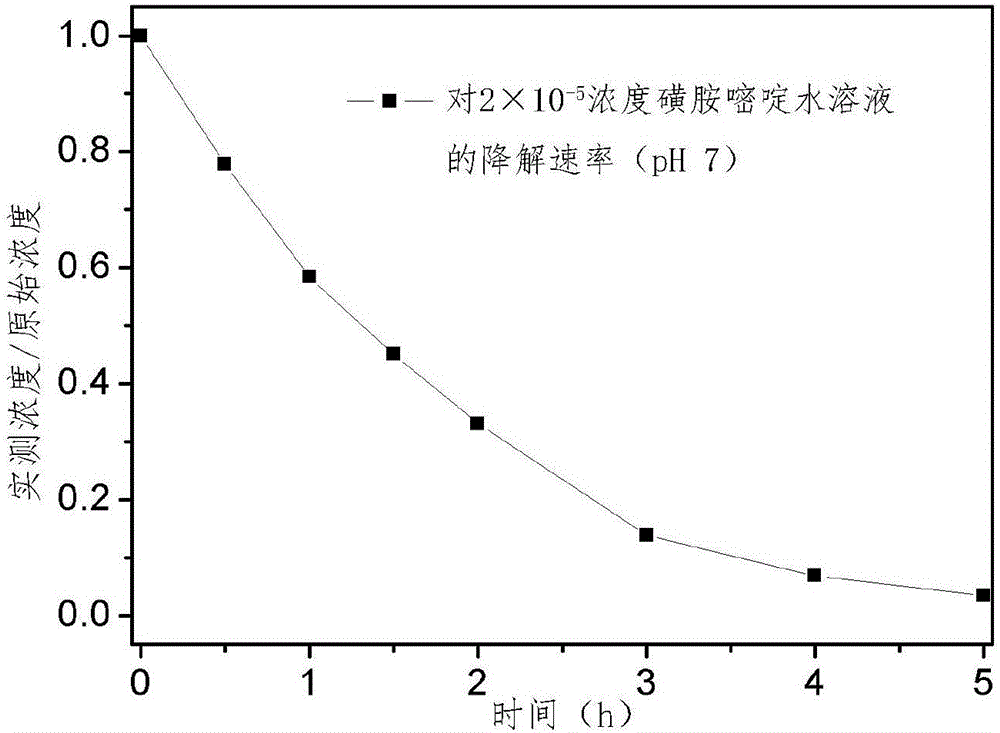

[0073] In the present invention, the skin-core composite photocatalytic fiber obtained in this embodiment is...

Embodiment 2

[0076] Weigh 100g of low-melting point sheath-core composite polyester fiber, the conventional polyethylene terephthalate with a core melting point of 260°C, the low-melting polyethylene terephthalate with a cortical melting point of 110°C, and the mass of the cortex Ratio is 60%, filament shape, diameter is 25 μm, put it into 5g / L composite photocatalyst (TiO 2 85%, g-C 3 N 4 15%) aqueous solution, bath ratio 1:40. The composite photocatalyst is adsorbed on the fiber by the method of three dipping and three rolling, and then put it in an oven at 80°C for pre-baking for 30 minutes, then continue to heat up to 110°C, bake for 40 minutes, wait for it to cool to room temperature, wash it with water to remove the insufficient adsorption on the fiber A firm catalyst can be dried in an oven at 60°C to obtain a skin-core composite photocatalytic fiber.

[0077] The present invention detects the skin-core composite photocatalytic fiber obtained in this example according to the meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com