Nano-fibrosis silk fibroin gel and preparation method thereof

A technology of silk fibroin and nanofibers, applied in medical science, prostheses, etc., can solve the problems of not having a bionic nanofiber structure, affecting the mechanical properties of silk fibroin hydrogel, and the complicated preparation process of silk fibroin hydrogel , to achieve the effects of strong maneuverability, avoiding the toxicity of the stent, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium bicarbonate solution for 30 minutes, and repeated 3 times to obtain degummed mulberry silk;

[0029] (2) Dissolve degummed silk in 2w / v calcium chloride-98wt% formic acid solution to obtain 10 w / v% silk protein solution;

[0030] (3) The above-mentioned silk fibroin solution was directly injected into a plastic tube, then immersed in deionized water, and nanofibrillated silk fibroin hydrogel was formed within 8 hours.

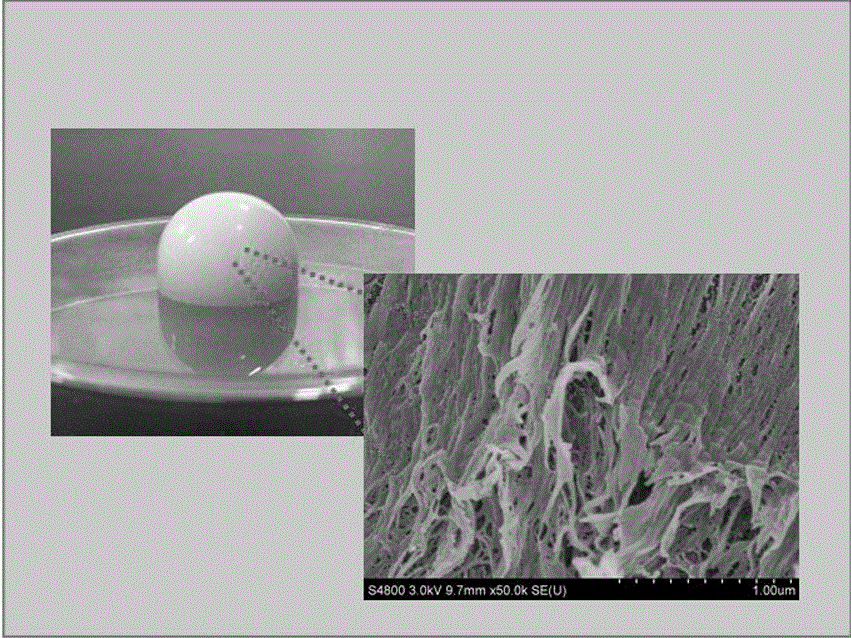

[0031] attached figure 1 It is a camera photo and a scanning electron microscope image after freeze-drying of the silk fibroin egg nanofiber hydrogel prepared above. It can be seen from the figure that the gel is milky white with a smooth surface, and the interior of the gel is mainly composed of silk fibroin nanofibrils. After mechanical compression test, the compressive modulus of the gel is 523.2KPa.

Embodiment 2

[0033] (1) Natural mulberry silk was degummed by boiling 0.05wt% sodium bicarbonate solution for 30 minutes, and repeated 3 times to obtain degummed mulberry silk;

[0034] (2) Dissolve degummed silk in 4w / v% calcium chloride-98wt% formic acid solution to obtain 25 w / v% silk protein solution;

[0035] (3) The above-mentioned silk fibroin solution was injected into a 24-well plate, and then immersed in deionized water, and nanofibrillated silk fibroin hydrogel was formed within 6 hours.

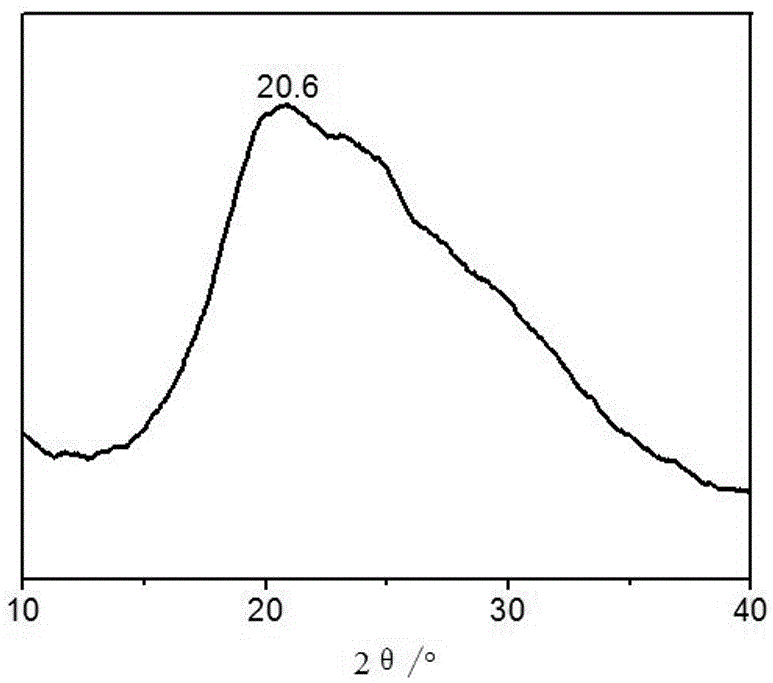

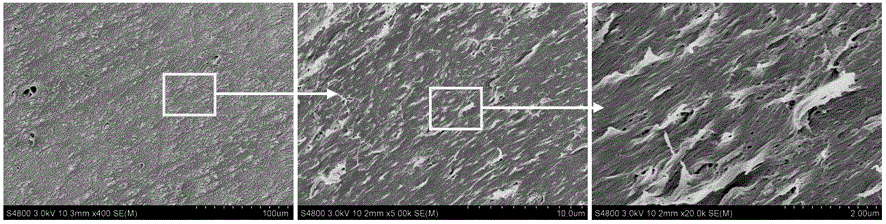

[0036] attached figure 2 , attached image 3 The X-ray diffraction spectrum and the scanning electron microscope picture after freeze-drying of the silk fibroin egg nanofiber hydrogel prepared above are respectively. It can be seen from the figure that the secondary structure of the silk protein is mainly a β-fold crystal structure, and the inside of the scaffold is composed of nano fiber composition. The compressive modulus of the gel was 16.2 MPa after mechanical compression test.

Embodiment 3

[0038] (1) Natural tussah silk was degummed by boiling with 0.5wt% sodium bicarbonate solution for 30 minutes, and the degummed tussah silk was obtained after repeating 3 times;

[0039] (2) Dissolving degummed tussah silk in 10w / v% lithium bromide-98wt% formic acid solution to obtain a silk protein solution with a concentration of 50w / v%;

[0040] (3) The above-mentioned silk fibroin solution was injected into a 6-well plate, then immersed in an aqueous solution, and tussah silk nanofibrillated silk fibroin hydrogel was formed within 20 hours.

[0041] attached Figure 4It is the scanning electron micrograph of the silk fibroin egg nanofiber hydrogel prepared above after freeze-drying. It can be seen from the figure that the interior of the hydrogel is also a nano-fibril structure. The compressive modulus of the gel was 98.2MPa after mechanical compression test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com