Production method for fermenting sour bamboo shoots without water

A production method and technology of sour bamboo shoots, which are applied in the field of food processing, can solve problems such as inducing cancer, reducing the flavor of sour bamboo shoots, and increasing the burden on the kidneys, and achieve the effects of promoting saliva secretion, promoting digestion, and enhancing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

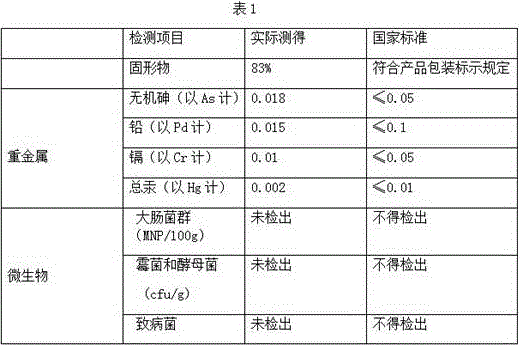

Examples

Embodiment 1

[0031] A production method of anhydrous fermentation of sour bamboo shoots, comprising the following steps:

[0032] (1) Selection of bamboo shoots: Choose bamboo shoots with a length of 60-65cm, dig out fresh and strong bamboo shoots that are not more than 24 hours old and moderately tender, cut off the thick and old fibers at the base of the bamboo shoots, then cut the bamboo shoots longitudinally with a knife, peel off the shells, Peel the skin and leave the core, the bamboo shoots are free of diseases and insect pests after peeling, and then use a slicer to cut the bamboo shoots into bamboo shoots with a length of 4-5 cm, a width of 1.5-2 cm, and a thickness of 0.15-0.2 cm to obtain fresh bamboo shoots;

[0033] (2) Soaking: add fresh water to immerse fresh bamboo shoots, soak them at room temperature for 10 hours, pick up and drain the bamboo shoots, and control the water content of the bamboo shoots to 92%-95%;

[0034] (3) Preparation: According to the weight ratio of b...

Embodiment 2

[0039] A production method of anhydrous fermentation of sour bamboo shoots, comprising the following steps:

[0040] (1) Selection of bamboo shoots: Choose bamboo shoots with a length of 65-70cm, dig out fresh and strong bamboo shoots that are not more than 24 hours old and moderately tender, cut off the thick and old fibers at the base of the bamboo shoots, then cut the bamboo shoots longitudinally with a knife, peel off the shells, Peel the skin and leave the core, the bamboo shoots are free of diseases and insect pests after peeling, and then use a slicer to cut the bamboo shoots into bamboo shoots with a length of 4-5 cm, a width of 1.5-2 cm, and a thickness of 0.15-0.2 cm to obtain fresh bamboo shoots;

[0041] (2) Soaking: Add fresh water to immerse fresh bamboo shoots, soak them at room temperature for 12 hours, pick up and drain the bamboo shoots, and control the water content of the bamboo shoots to 92%-95%;

[0042] (3) Blending: According to the weight ratio of bamb...

Embodiment 3

[0047] A production method of anhydrous fermentation of sour bamboo shoots, comprising the following steps:

[0048] (1) Selection of bamboo shoots: select bamboo shoots with a length of 70-75cm, dig out fresh and strong bamboo shoots that are not more than 24 hours old and moderately tender, cut off the thick and old fibers at the base of the bamboo shoots, and then use a knife to cut the shells longitudinally and peel off the shells. Peel the skin and leave the core, the bamboo shoots are free of diseases and insect pests after peeling, and then use a slicer to cut the bamboo shoots into bamboo shoots with a length of 4-5 cm, a width of 1.5-2 cm, and a thickness of 0.15-0.2 cm to obtain fresh bamboo shoots;

[0049] (2) Soaking: add fresh water to immerse fresh bamboo shoots, soak them at room temperature for 14 hours, pick up and drain the bamboo shoots, and control the water content of the bamboo shoots to 92%-95%;

[0050] (3) Deployment: According to the weight ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com