Sterilization treatment method of pickled vegetables through pulse type super-high pressure technique

A technology of ultra-high pressure technology and treatment method, which is applied in the field of sterilization treatment of pickled vegetables, which can solve the problems of limited effect, destruction of flavor and nutritional components, and failure of thermal sterilization process to protect nutritional components and senses, etc., to achieve short processing time and reduce Energy consumption, effect of extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

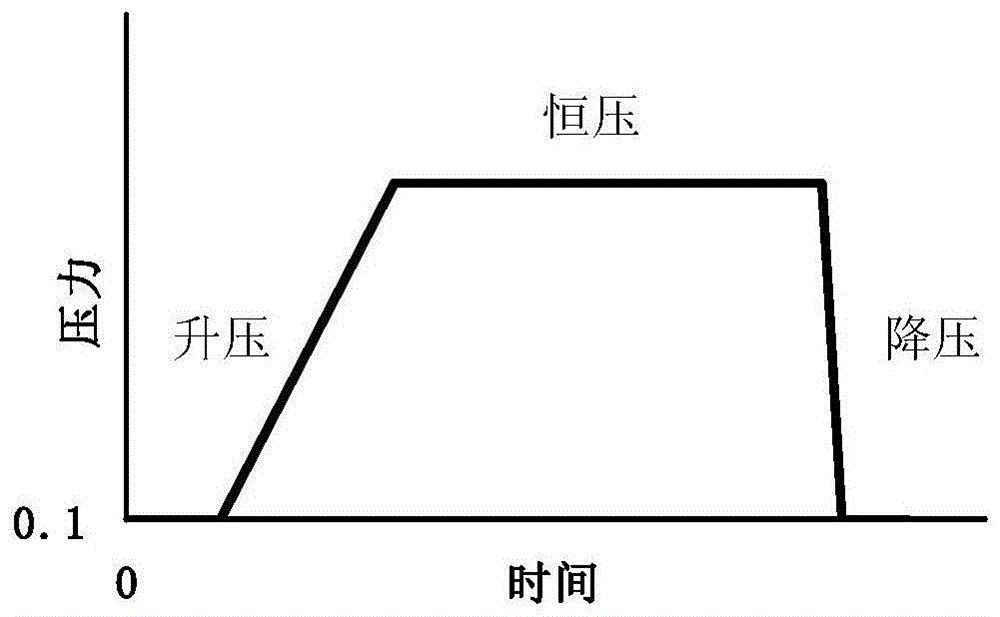

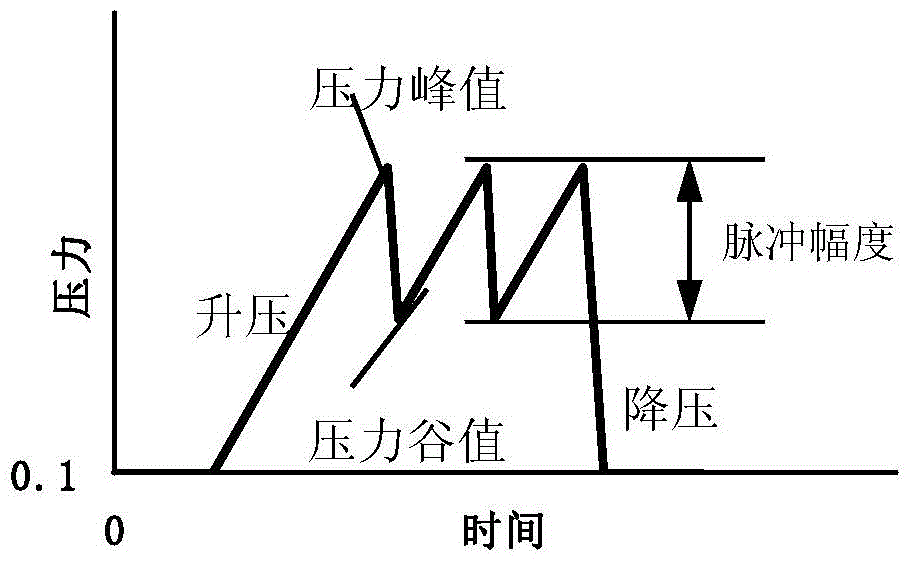

Method used

Image

Examples

Embodiment 1

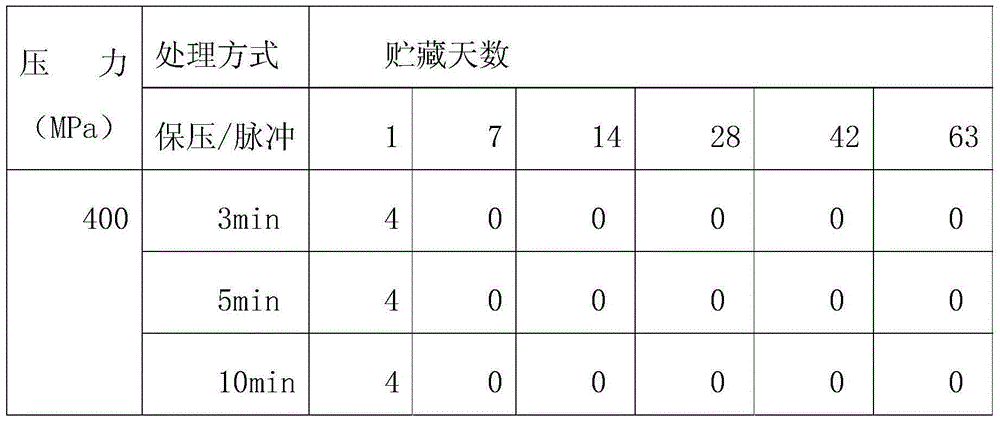

[0019] Pickled radish without preservatives was used as a sample, and after constant pressure ultra-high pressure treatment and pulse ultra-high pressure treatment, the expansion experiment was carried out under the storage condition of 37 ° C. Each group had 4 packages of samples. For the specific treatment conditions, see Table 1, see Table 1 for the results of the swelling test.

[0020] Table 1 The swelling test results of pickled radish under the storage condition of 37 ℃ after constant pressure ultra-high pressure treatment

[0021]

[0022]

[0023] Note: The data in the table is the number of unexpanded bags of pickled radish under the corresponding conditions

[0024] It can be seen from the results in Table 1 that the constant pressure ultra-high pressure treatment requires a long holding time (600MPa, more than 5min) to achieve the ideal sterilization effect. Under the condition of 600MPa, more than two pulses can ensure the storage of pickled radish To 63 da...

Embodiment 2

[0026] Pickled cucumbers without preservatives were used as samples, and after constant-pressure ultra-high pressure treatment and pulse-type ultra-high pressure treatment, the expansion experiment was carried out under the storage condition of 37 ° C. Each group had 4 packages of samples. For the specific treatment conditions, see Table 2, see Table 2 for the results of the swelling test.

[0027] Table 2

[0028]

[0029]

[0030] Note: The data in the table is the number of unexpanded pickled cucumber bags under the corresponding conditions

[0031] It can be seen from the results in Table 2 that the constant pressure ultra-high pressure treatment requires a long holding time (600MPa, more than 5min) to achieve the ideal sterilization effect. Under the condition of 600MPa, more than two pulses can ensure the storage of pickled melon To 63 days, without swelling phenomenon (table 2). It can be seen that the pulsed ultra-high pressure treatment can strengthen the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com