Functional mixed gel type soft sweets and manufacturing method thereof

A kind of mixed glue and functional technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of excellent taste and toughness, mutual adhesion, sugar body collapse, etc. Deformation rate, the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

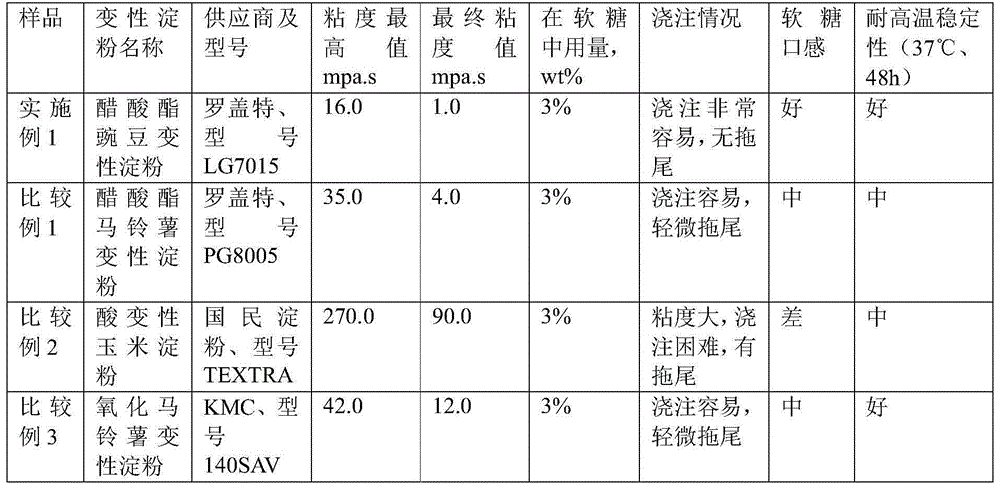

[0048] Embodiment 1: adopt following formula to manufacture the fudge of embodiment 1:

[0049] 6.5wt% gelatin; 3wt% acetate pea modified starch; 0.6wt% high methoxyl pectin; 30wt% xylitol; 45wt% polydextrose; 0.5wt% DHA algae oil; 2wt% Sorbitol solution; 3wt% concentrated apple juice, 2.2wt% 50wt% citric acid solution, 0.3wt% sodium citrate buffered salt, and 0.15wt% natural essence and pigment.

Embodiment 3

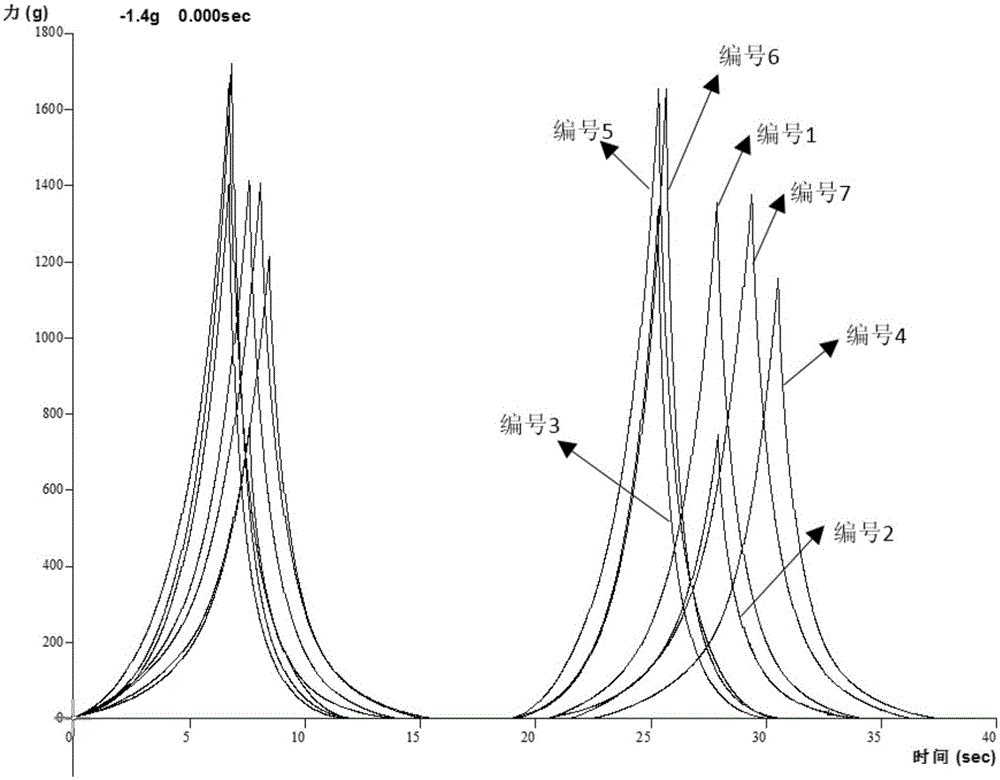

[0065] Embodiment 3 gelatin, pectin, modified starch composite ratio experiment

[0066] The TPA texture test used in the present embodiment uses the following instruments and parameters:

[0067] Texture analyzer: TA-XT2i texture analyzer

[0068] Measurement parameter setting: probe P / 36R, pre-test speed 2.0mm / s, measurement speed 1.0mm / s, post-test speed 1.0mm / s, deformation 50%, time 5s, trigger force 5.0g, data recording rate 200pps.

[0069] In order to further determine the amount of gelatin, pectin, and modified starch in the functional mixed gum type jelly candy of the present invention, in the following preparation examples 1-9, through the method in Example 1, different three additions are used. Prepared different soft candies, and carried out the experiments shown in the table below, and evaluated the gel strength, elasticity, chewiness, bite resistance, thermal stability, and taste preference of the soft candies obtained. with TPA assessment. The results are as...

Embodiment 5

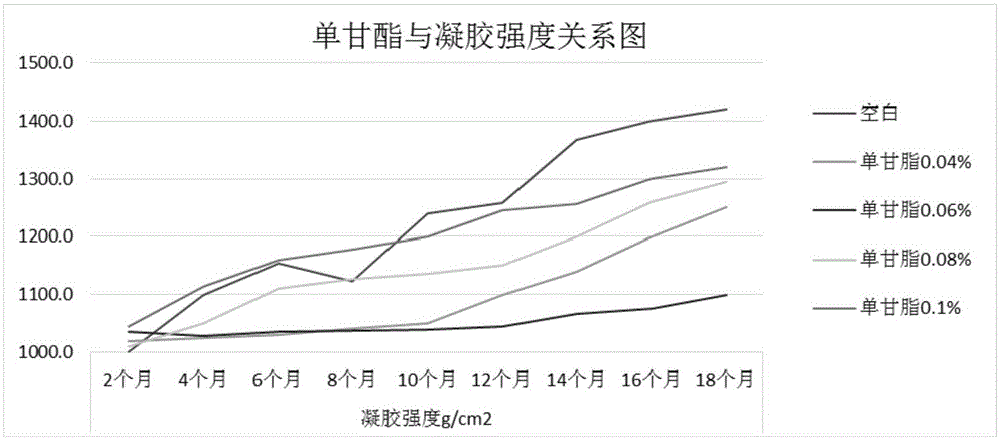

[0078] Embodiment 5 Modified starch aging retrogradation test

[0079] In the manufacturing process of the functional mixed gum soft candy of the present invention, in order to prevent the retrogradation of the modified starch, 0.04-0.1wt% glyceryl monostearate was added on the basis of the soft candy in Example 1, and different The aging retrogradation of modified starch under the addition amount was compared. The results are shown in Table 5 below:

[0080] Table 5 Aging retrogradation test of modified starch

[0081]

[0082] From the results in the table above, it can be seen that adding 0.04-0.1 wt% glyceryl monostearate in the ingredients of the present invention can effectively delay the phenomenon of retrogradation of the modified starch, and the taste of the soft candy basically does not change during the shelf life. Preferably, the optimum addition amount of glyceryl monostearate is 0.06 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com