Substrate integrated ridge waveguide slot array broadband leaky-wave antenna

A substrate-integrated waveguide and slot array technology, applied in slot antennas, antennas, antenna arrays, etc., can solve the problems of low side lobes, inability to meet high gain, etc., and achieve high gain, easy processing and integration, and the effect of expanding the working frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

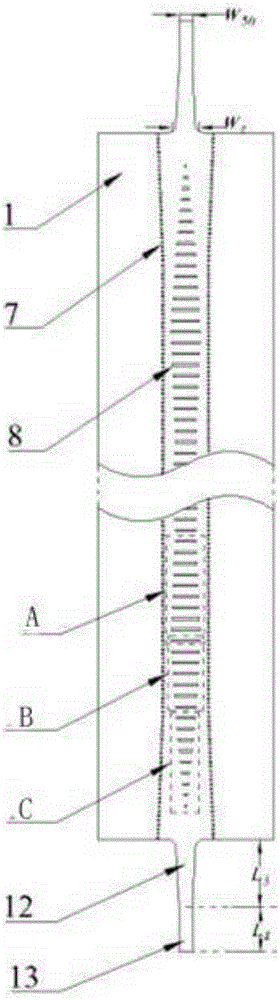

[0048] Such as Figure 1 to Figure 9 A substrate-integrated ridge waveguide slot array broadband leaky-wave antenna is shown, which has a symmetrical structure with respect to the H plane, including a substrate-integrated waveguide and a ridge metal layer 3, and the substrate-integrated waveguide includes a lower metal layer 5 and a lower dielectric plate 4. The upper dielectric plate 2 and the upper metal layer 1;

[0049] In this embodiment, the lower metal layer 5, the lower dielectric plate 4, the ridge metal layer 3, the upper dielectric plate 2 and the upper metal layer 1 are stacked in sequence;

[0050] A row of side vias 6 are respectively provided on both sides of the ridge metal layer 3 in this embodiment, and the side vias 6 pass through the lower metal layer 5 , the lower dielectric plate 4 , the upper dielectric plate 2 and the upper metal layer 1 in sequence;

[0051] In this embodiment, a row of middle vias 7 is provided on the centerline of the lengthwise dir...

Embodiment 2

[0054] On the basis of the structure of Embodiment 1, the ridge metal layer 3 is strip-shaped, and its width is greater than the diameter of the middle via hole 7 , and the length of the ridge metal layer 3 is greater than the length of the substrate integrated waveguide.

[0055] The distance between two adjacent middle via holes 7 is 0.03λ to 0.05λ, and λ is the center frequency wavelength;

[0056] The diameter of the side via holes 6 in this embodiment is 0.017λ˜0.027λ, and the distance between two adjacent side via holes 6 in each row is less than or equal to the diameter of the side via holes 6;

[0057] In this embodiment, the diameters of the side via hole 6 and the middle via hole 7 are equal, and the height of the middle via hole 7 is half of the height of the side via hole 6 .

[0058] The ridge metal layer 3 above the metal spine is designed to further expand the bandwidth based on the ridge waveguide. The metal strip must have a certain lateral width in order to ...

Embodiment 3

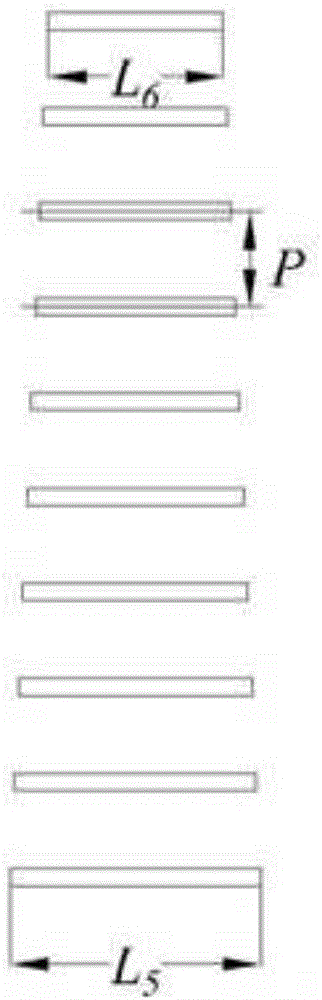

[0061] On the basis of the above embodiments, a leaky wave structure is also included, and the leaky wave structure includes a row of transverse grooves 8 arranged on the upper metal layer 1 .

[0062] The widths of the transverse grooves 8 are equal, and the intervals between two adjacent transverse grooves are equal.

[0063] The lengths of the transverse grooves 8 are periodically distributed, and the maximum length of the transverse grooves 8 is 0.2λ˜0.25λ, and the minimum length is 0.15λ˜0.2λ in each length variation period.

[0064] The most important part in the structure of the leaky wave antenna is the leaky waveguide with a certain length. In the present invention, a series of horizontal grooves are opened for the upper metal layer 1 to integrate the ridge waveguide. The propagation characteristics of the waveguide leaky mode in the wave propagation direction Determined by the phase constant β and the leakage constant α. In order to couple more electromagnetic waves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com