Preparation method and application of Ti3+ doped TiO2 nanotube array/sulfonated poly phenol membrane electrode

A technology of sulfonated polyphenol membrane and nanotube array, which is applied in the direction of nanotechnology, nanotechnology, battery electrodes, etc., can solve the problems of unfavorable electrolyte wetting lithium ion transmission, poor gas permeability and lyophilicity, and affecting battery performance. Achieve the effects of improving electrochemical performance, reducing battery internal resistance, and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Ti described in this example 3+ doped TiO 2 The preparation method of nanotube array / sulfonated polyphenol membrane electrode, concrete steps are as follows:

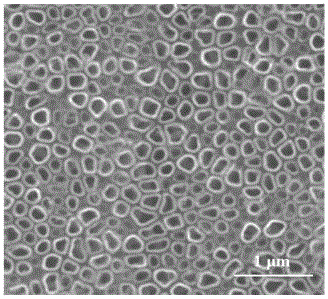

[0035] (1) Using the anodic oxidation method, a clean titanium sheet is used as the working electrode, a platinum electrode is used as the counter electrode, and the mass percentage is 0.5% NaF and 14.5% H 2 The mixed solution of O and glycerol is the electrolyte, and the anodic oxidation is carried out at a constant voltage (30V) for 2 hours, and the working electrode is washed and dried to obtain a three-dimensional ordered TiO 2 nanotube array TiO 2 NT;

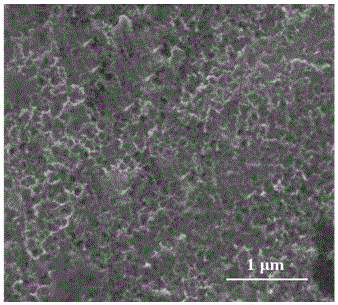

[0036] (2) In the three-electrode system, TiO prepared by step (1) anodic oxidation 2 NT is the working electrode, the platinum electrode is the counter electrode, the saturated calomel electrode is the reference electrode, and the concentration is 1.0mol / L Na 2 SO 4 The solution is an electrolyte, and the constant voltage (-1.0V) reacts for 200s to obt...

Embodiment 2

[0041] Ti described in this example 3+ doped TiO 2 The preparation method of nanotube array / sulfonated polyphenol membrane electrode, concrete steps are as follows:

[0042] (1) Using the anodic oxidation method, a clean titanium sheet is used as the working electrode, a platinum electrode is used as the counter electrode, and the mass percentage is 0.3% NH 4 F, 14.7% H 2 The mixed solution of O and glycerin is the electrolyte, and the anodic oxidation is carried out at a constant potential (40V) for 4 hours, and the working electrode is washed and dried to obtain a three-dimensional ordered TiO 2 nanotube array TiO 2 NT;

[0043] (2) In the three-electrode system, TiO prepared by step (1) anodic oxidation 2 NT is the working electrode, the platinum electrode is the counter electrode, the saturated calomel electrode is the reference electrode, and the H concentration is 2.5mol / L. 2 SO 4 The solution is an electrolyte, and the constant voltage (-1.5V) reacts for 20s to o...

Embodiment 3

[0048] Ti described in this example 3+ doped TiO 2 The preparation method of nanotube array / sulfonated polyphenol membrane electrode, concrete steps are as follows:

[0049] (1) Using the anodic oxidation method, the cleaned titanium sheet is used as the working electrode, the platinum electrode is the counter electrode, and the mass percentage is 0.7% HF, 14.3% H 2 The mixed solution of O and glycerol is the electrolyte, anodized by constant potential (20V) for 1h, the working electrode is rinsed and dried to obtain three-dimensional ordered TiO 2 nanotube array TiO 2 NT;

[0050] (2) In the three-electrode system, TiO prepared by step (1) anodic oxidation 2 NT is the working electrode, the platinum electrode is the counter electrode, the saturated calomel electrode is the reference electrode, and the concentration is 2.0mol / L Na 2 SO 4 The solution is an electrolyte, and the constant voltage (-0.5V) reacts for 600s to obtain Ti 3+ Doped TiO 2 NT composite electrode T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com