Method of realizing photoetching of rewiring metal layer

A metal layer and rewiring technology, which is applied in the field of rewiring metal layer lithography, can solve the problem of low yield rate of rewiring metal layer, and achieve the effect of eliminating air bubbles, improving quality and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As mentioned in the background, with the further increase of the process node, the yield rate of the redistribution metal layer formed in the prior art is low.

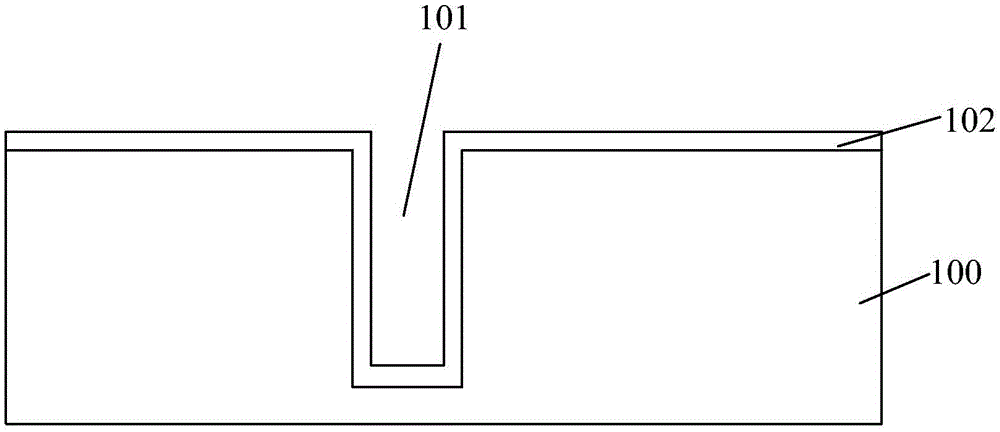

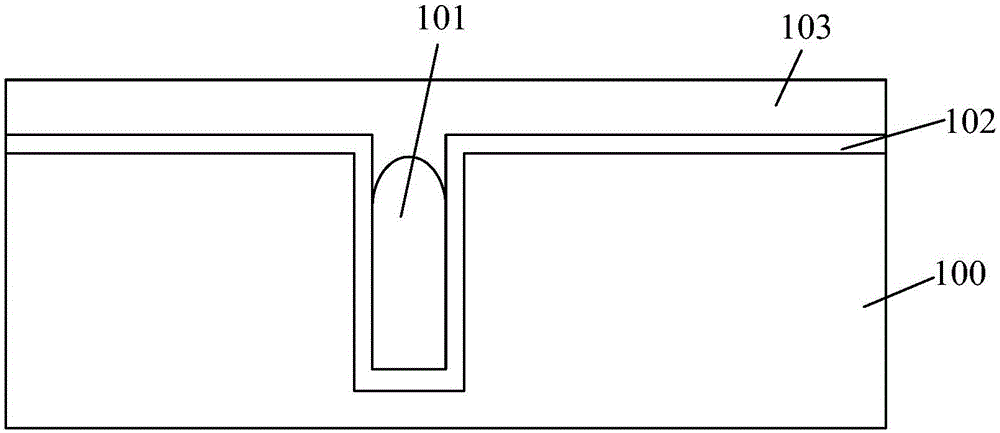

[0027] After further research, it was found that the low yield rate of the rewiring metal layer was mainly caused by the photoresist layer used to transfer the rewiring pattern. Specifically, please refer to figure 2 and image 3 , as the process node further increases, the size of the silicon hole 101 formed in the silicon wafer 100 becomes smaller and smaller. When the photoresist 103 is spin-coated on the surface of the silicon wafer 100, if the spin-coated photoresist is thinner, it is difficult to As a mask for subsequent etching to form the rewiring metal layer; if the photoresist that is spin-coated is thicker, it is difficult to completely fill the silicon hole 101 due to its high viscosity, and the photoresist is deposited on the top of the silicon hole 101. It is difficult to enter the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com