Acid rock reaction single-rock-plate crack simulation device and working method thereof

A technology for simulating device and acid-rock reaction, which is applied in the direction of material inspection, soil material testing, etc. It can solve the problems that the growth rate of wormholes cannot be directly calculated, the number of experimental groups is small, and the visibility is poor, so that it is easy to disassemble and repeat Experimental, the effect of compact overall structure and strong pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

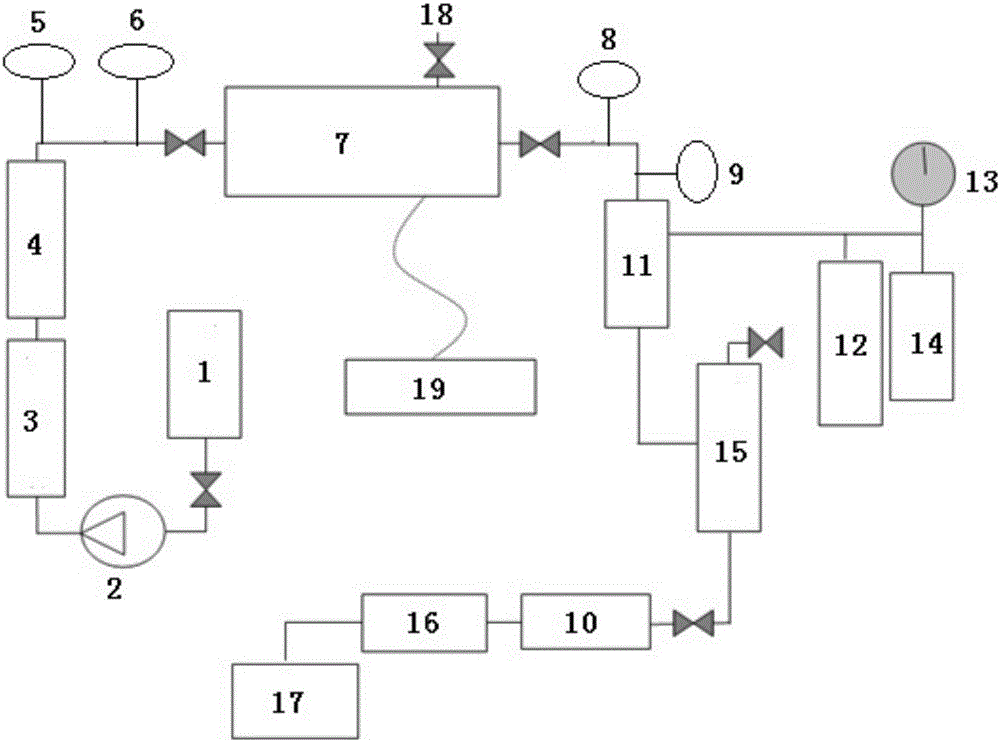

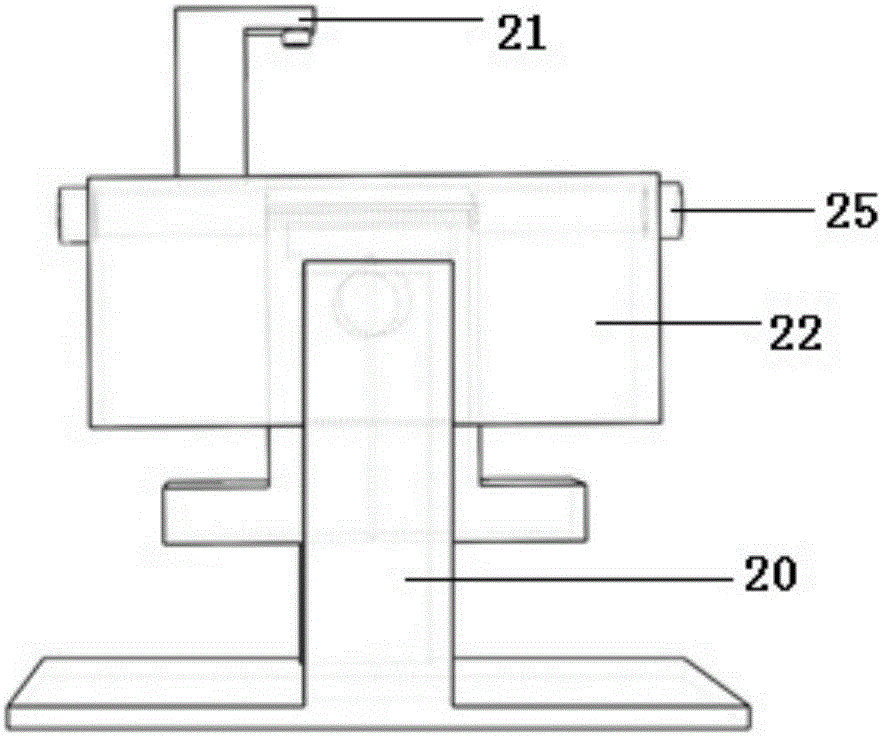

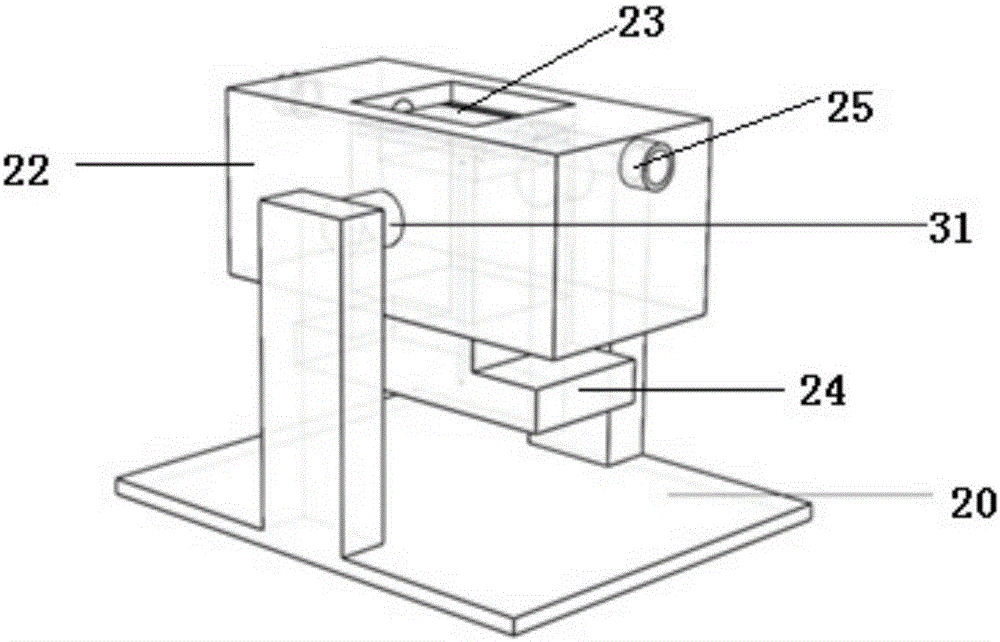

[0047] An acid rock reaction single rock slab crack simulation device, such as figure 1 As shown, it includes injection system, preheating system, inlet detection system, visual flat panel model 7, outlet detection system, condenser 16, back pressure system, waste liquid recovery system and data processing system 19; injection system, preheating system, The inlet inspection system, visual flat panel model, outlet inspection system 7, back pressure system, condenser 16, and waste liquid recovery system are connected sequentially;

[0048] The injection system provides injection power for the single rock slab fracture simulation device and adjusts the speed of acid injection; the inlet detection system is used to collect the pressure, temperature, and flow rate of the fluid at the inlet end of the visible flat plate model 7; the preheating system will inject acid The fluid is preheated to the temperature required by the experiment; the visual flat panel model 7 is used to dynami...

Embodiment 2

[0066] The working method of the acid-rock reaction single rock slab crack simulation device described in embodiment 1, the specific steps include:

[0067] (1) Select stratum rocks, i.e. carbonate rocks, process the stratum rocks into rock slabs 27, put them into the slotted plate corrosion holder, connect the acid-rock reaction single rock slab crack simulation device, and open the data processing system 19;

[0068] (2) Open the gas vent valve 18, adjust the pressure balance in the acid rock reaction single rock slab crack simulation device, and close the gas vent valve 18;

[0069] (3) configuration mass concentration is 18% acid solution, pours in intermediate container 1; Open preheating coil 3, temperature is adjusted to 70 ℃; Open back pressure system, set the back pressure of 4Mpa; Open inlet flowmeter 4 , inlet pressure sensor 5, inlet temperature detector 6, outlet flowmeter 10, outlet pressure sensor 8, outlet temperature detector 9, condenser 16, microscope 21;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com