Water heating system

A technology for water heating system and hot water tank, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as easy scaling, reduce thermal stress, reduce heat resistance index requirements, and ensure The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

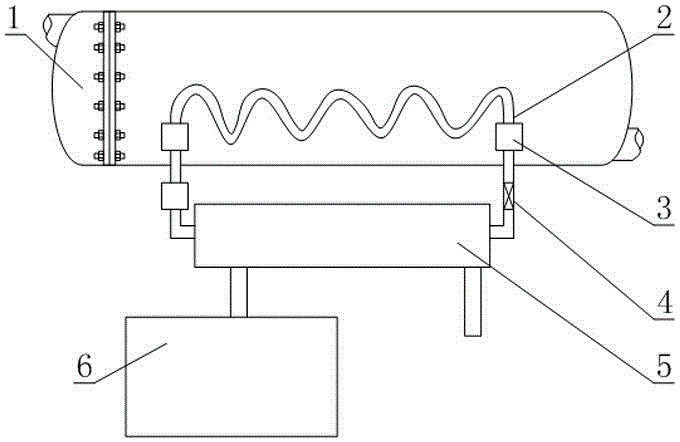

[0026] Such as figure 1 As shown, a water heating system includes a hot water tank 1, a combustion stove 6, and a flue gas pipe 5 for exhausting smoke from the combustion stove, and also includes a heat-conducting oil pipe 2 for containing heat-conducting oil, and the heat-conducting oil pipe 2 is annular Pipeline, the heat conduction oil pipe 2 passes through the hot water tank 1 and the flue gas pipe 5;

[0027] It also includes at least two expansion joints 3, the expansion joints 3 are connected in series on the heat transfer oil pipe 2, and at least one expansion joint 3 is provided on the heat transfer oil pipe 2 inside the hot water tank 1 and the heat transfer oil pipe 2 outside the hot water tank 1 ;

[0028] It also includes a circulation pump 4 for driving the heat transfer oil in the heat transfer oil pipe 2 to circulate.

[0029] Specifically, the above-mentioned combustion stove 6 is used for burning straw fuel, and the high-temperature flue gas produced is dis...

Embodiment 2

[0032] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: since the hot water tank 1 is connected to the water pipe network, it is equivalent to an internal pressure container, in order to make the hot water tank 1 have better pressure resistance , the hot water tank 1 includes a cylindrical body and heads respectively fixed to different ends of the body, and the heads are hemispherical or elliptical.

[0033] In order to facilitate the installation and maintenance of the heat transfer oil pipe 2 in the hot water tank 1, one of the sealing heads is connected to the flange of the barrel body, and the other sealing head is connected to the barrel body by welding.

[0034] Since the density of water with a higher temperature is smaller than that of water with a lower temperature, in order to ensure that the water discharged from the hot water tank 1 is hot water as much as possible, the hot water tank 1 is also connected with an inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com