A high-temperature flue gas recirculation pre-combustion low NOx burner equipped with sofa

A high-temperature flue gas and burner technology, which is applied in the combustion of solid fuels, combustion methods, combustion equipment, etc., can solve problems such as backward emission control, achieve stable combustion, reduce NOx generation, good ignition and combustion stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

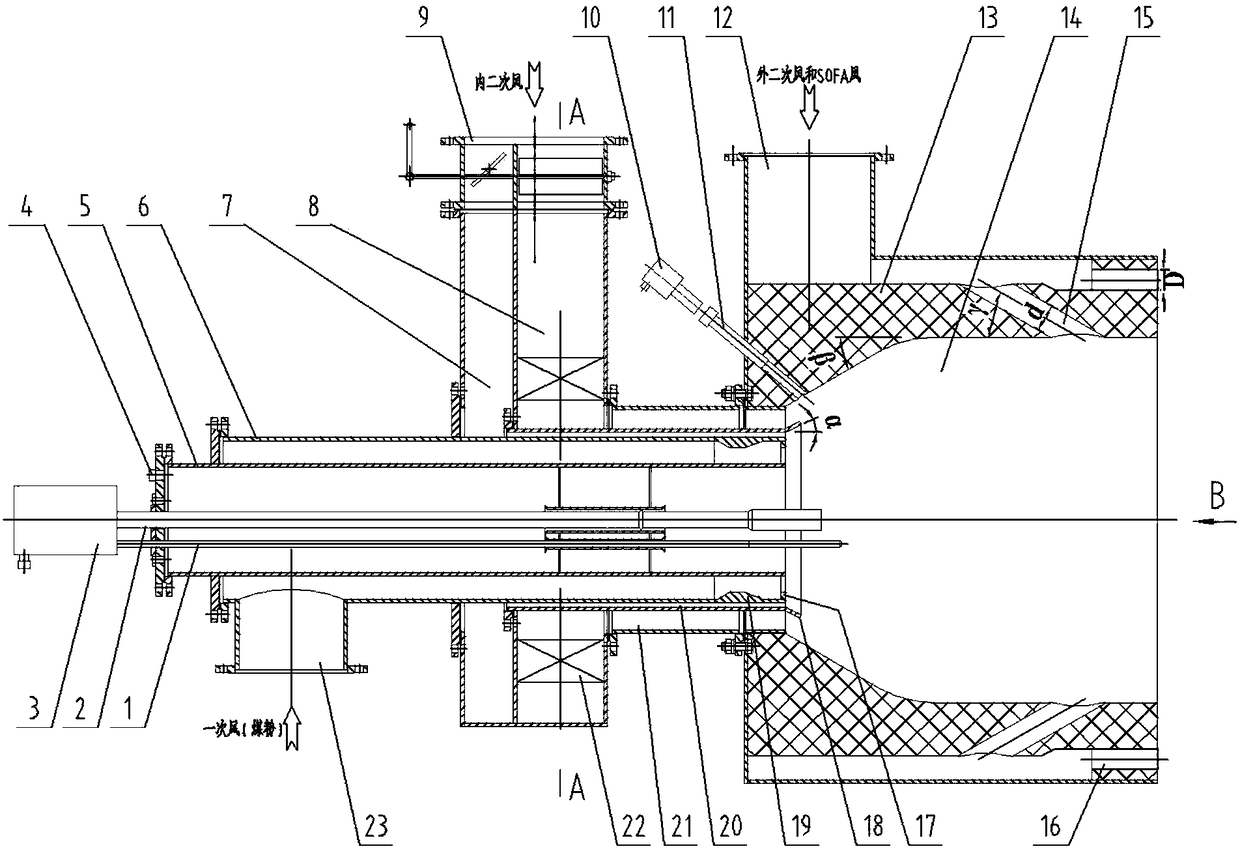

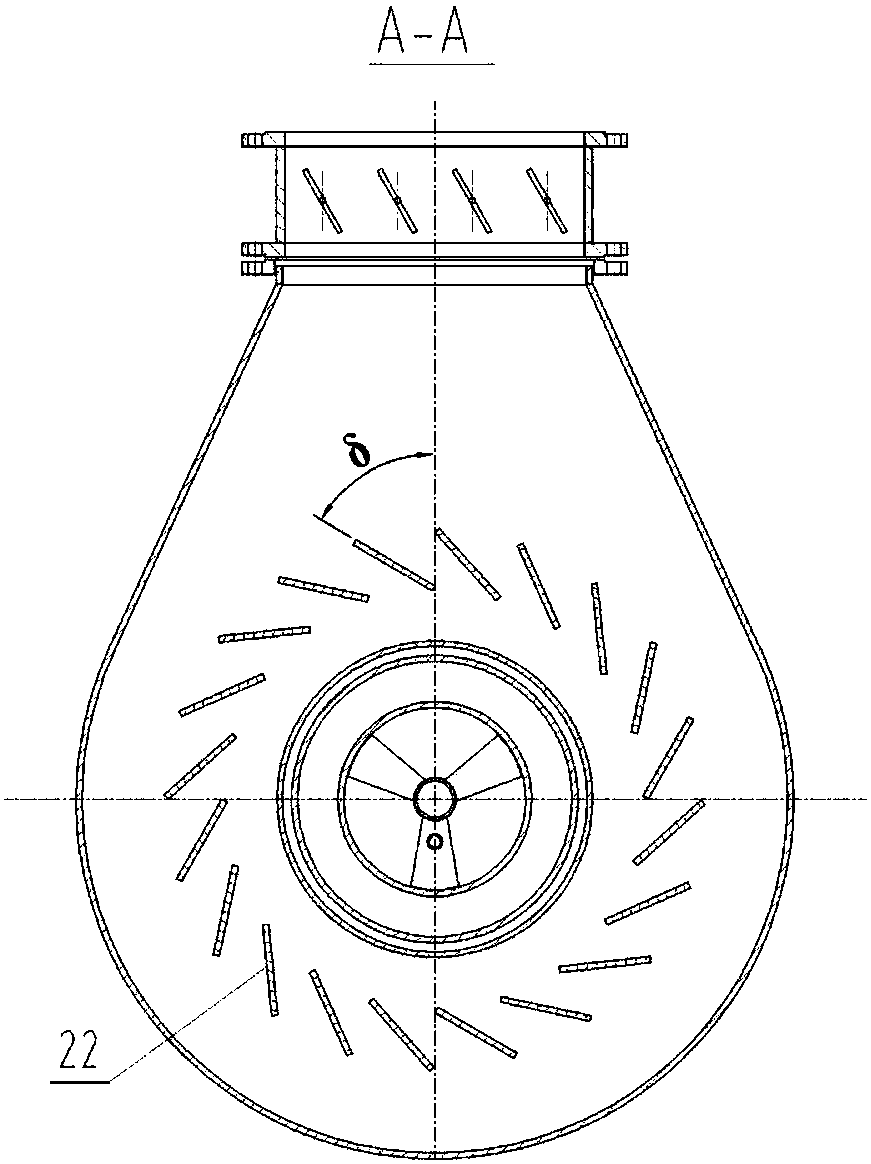

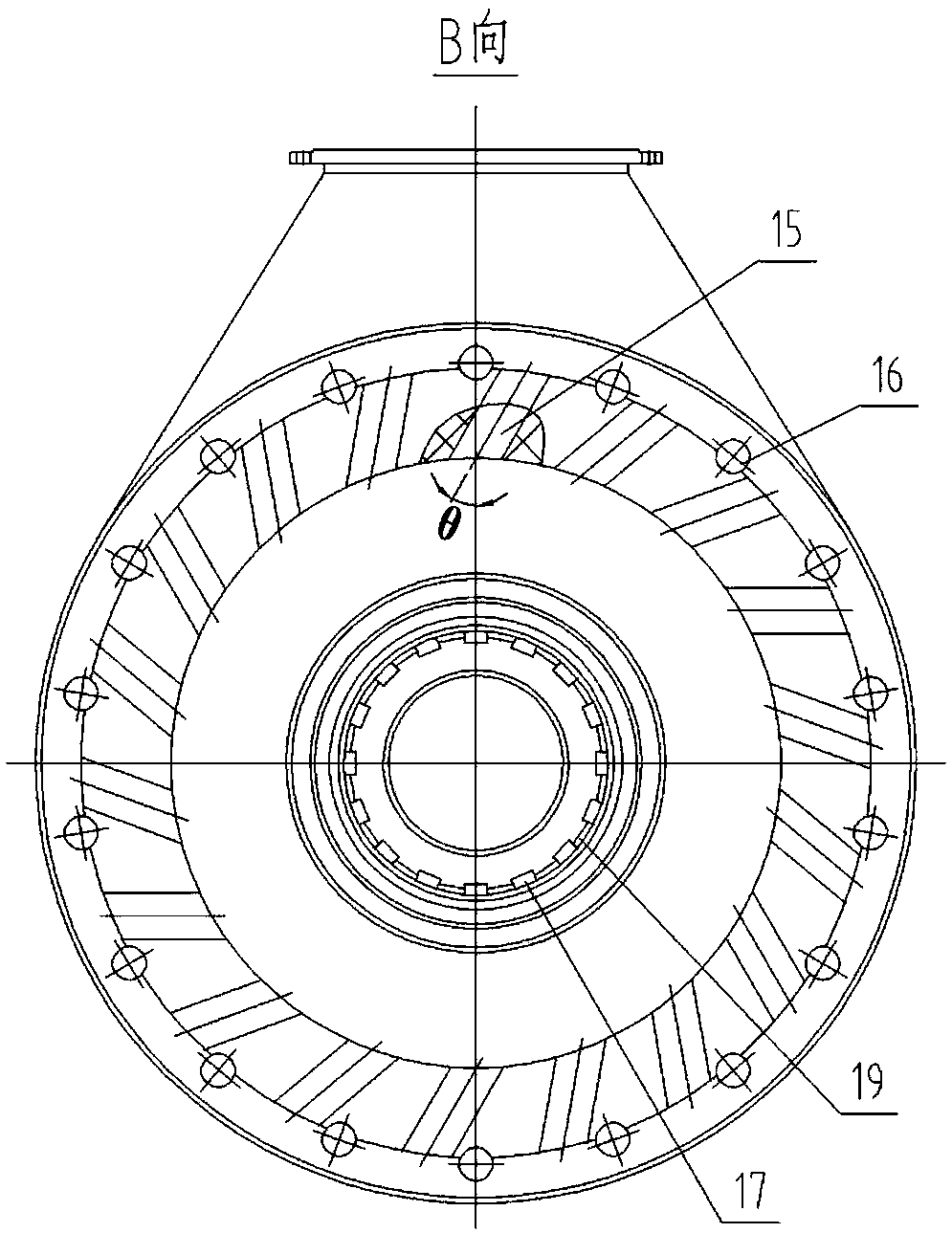

[0026] see Figure 1-Figure 4 , the present invention consists of ignition system (high-energy ignition device 1, oil gun 2, combined pneumatic propeller 3), core tube 5, primary air sleeve 6, flame-stabilizing teeth 17, pulverized coal concentration ring 19, direct-current internal secondary Air channel 7, secondary air channel 8 in swirling flow, secondary air sleeve 20 in direct current, secondary air sleeve 21 in swirling flow, flap valve 9, infrared flame monitoring device 10, fire viewing device, pre-combustion chamber Housing, pre-combustion chamber 14, external secondary air nozzle 15, SOFA air direct-flow nozzle 16 and so on.

[0027]The present invention comprises a pre-combustion chamber 14, a central core tube 5 is arranged on one side of the entrance of the pre-combustion chamber 14, and a primary air sleeve 6, a DC internal secondary air sleeve 20 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com