Breeze combustion method and device

A pulverized coal burner and pulverized coal combustion technology are applied to burners, combustion methods, and burners for burning powder fuels to achieve the effects of reducing NOX generation, high-efficiency and low-oxygen combustion, and accelerating ignition and combustion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

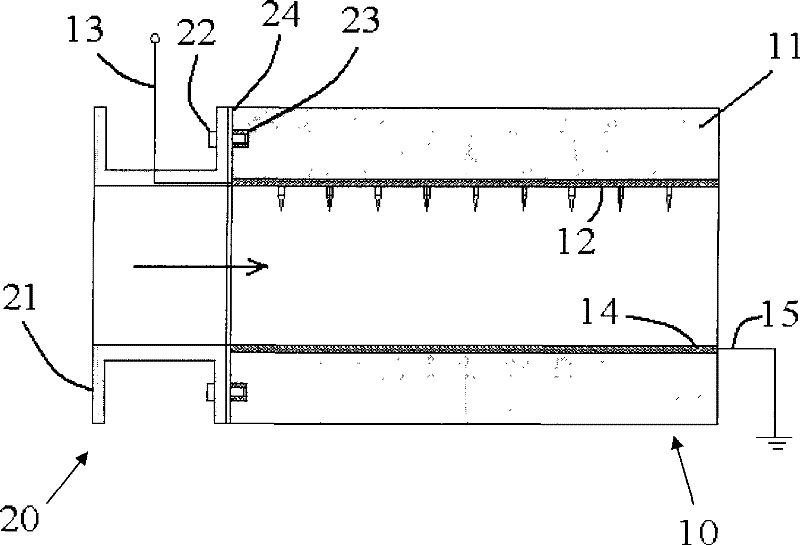

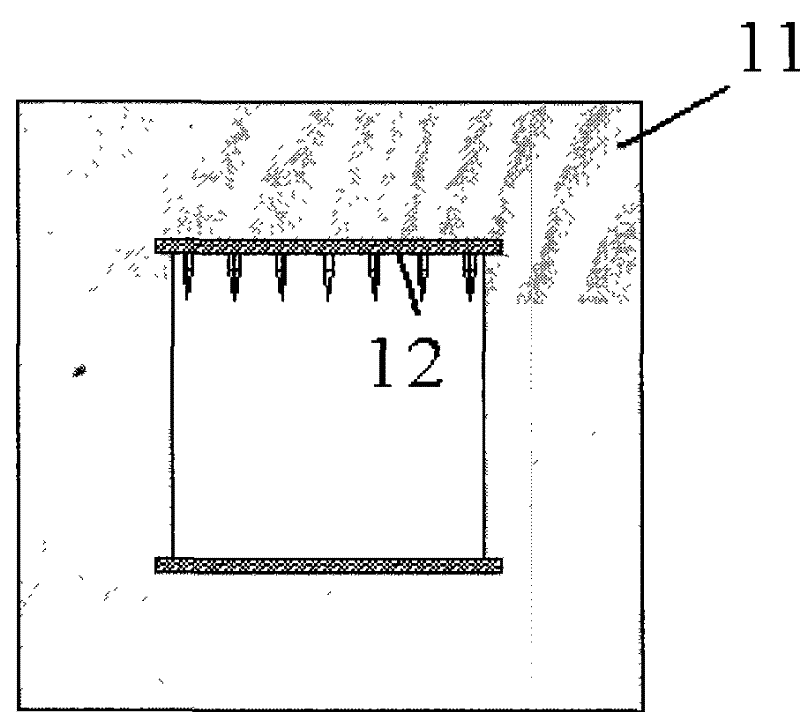

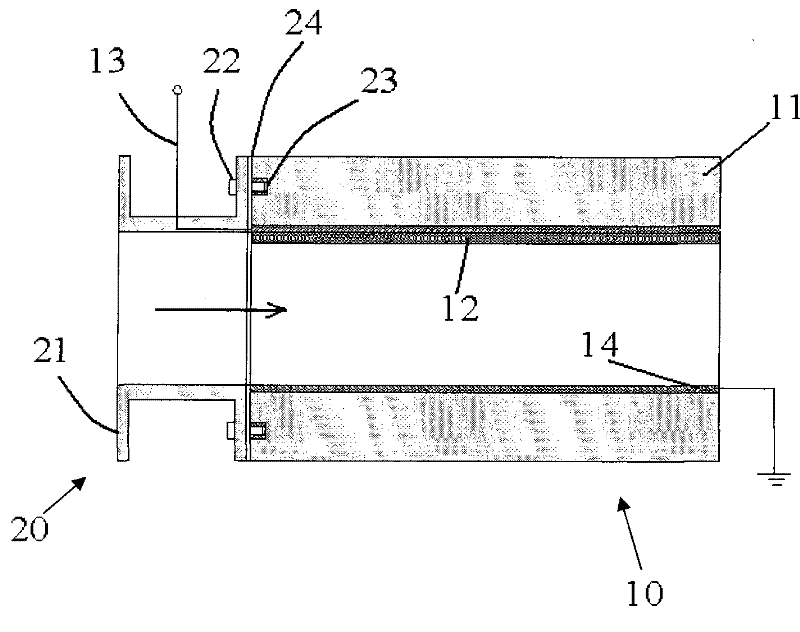

[0018] like figure 1 , 2 As shown, the burner of the present invention is mainly composed of a burner nozzle 10 and an insulating connecting piece 20 (see figure 1 shown). The burner nozzle 10 includes an outer insulating casing 11, and the casing 11 is provided with: a non-flat corona plate 12, which is connected to an external power source through a high-voltage cable 13, and the power source can use either positive or negative corona high voltage The DC power supply can also use a positive or negative corona pulse high-voltage DC power supply; The insulating connector 20 includes an insulating temperature-resistant and wear-resistant flange 21 , a connecting bolt 22 , a nut 23 , a sealing washer 24 and the like.

[0019] The burner nozzle 10 of the present invention is connected to the primary air duct by an insulating flange 21, and the burner 10, the connecting duct and the furnace body should be safely grounded to ensure that the high voltage does not pose a danger to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com