Straight-type rice pot seedling wide and narrow row transplanting mechanism

A technology of wide and narrow rows and potted seedlings, which is applied in the direction of transplanting machinery, mechanical equipment, portable lifting devices, etc., can solve the problems of low seedling success rate, unsatisfactory, and limited functions, and achieve simple mechanism structure and reduced number of gears. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

[0053] The first transplanting mechanism scheme to realize direct-take pot seedling transplanting:

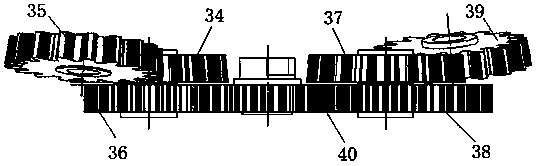

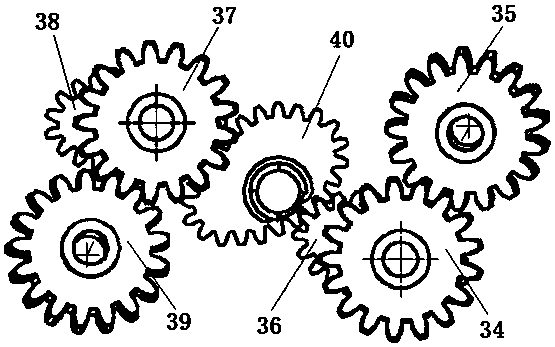

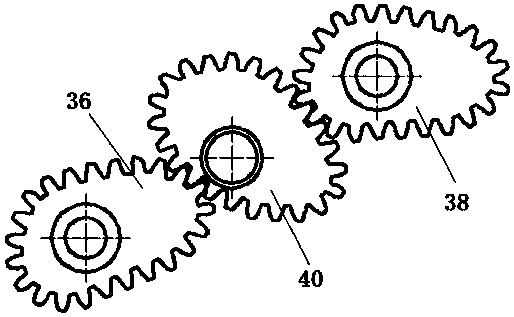

[0054] Such as figure 1 , figure 2 and image 3 As shown, the direct-taking rice pot seedling wide and narrow row transplanting mechanism includes a transmission case 21, a planetary gear train, an upper transplanting arm 15 and a lower transplanting arm 7; two planetary gear trains are arranged symmetrically on both sides of the transmission case; The upper transplanting arm 15 and the lower transplanting arm 7 are respectively arranged at the two ends of the wheel train; the central shaft 2 and the driving sprocket shaft 20 are all supported on the transmission box 21 by bearings, and the driving sprocket 19 fixed on the driving sprocket shaft 20 is connected with the fixed The central sprocket 1 on the central shaft 2 is connected by a chain 18 .

[0055] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com