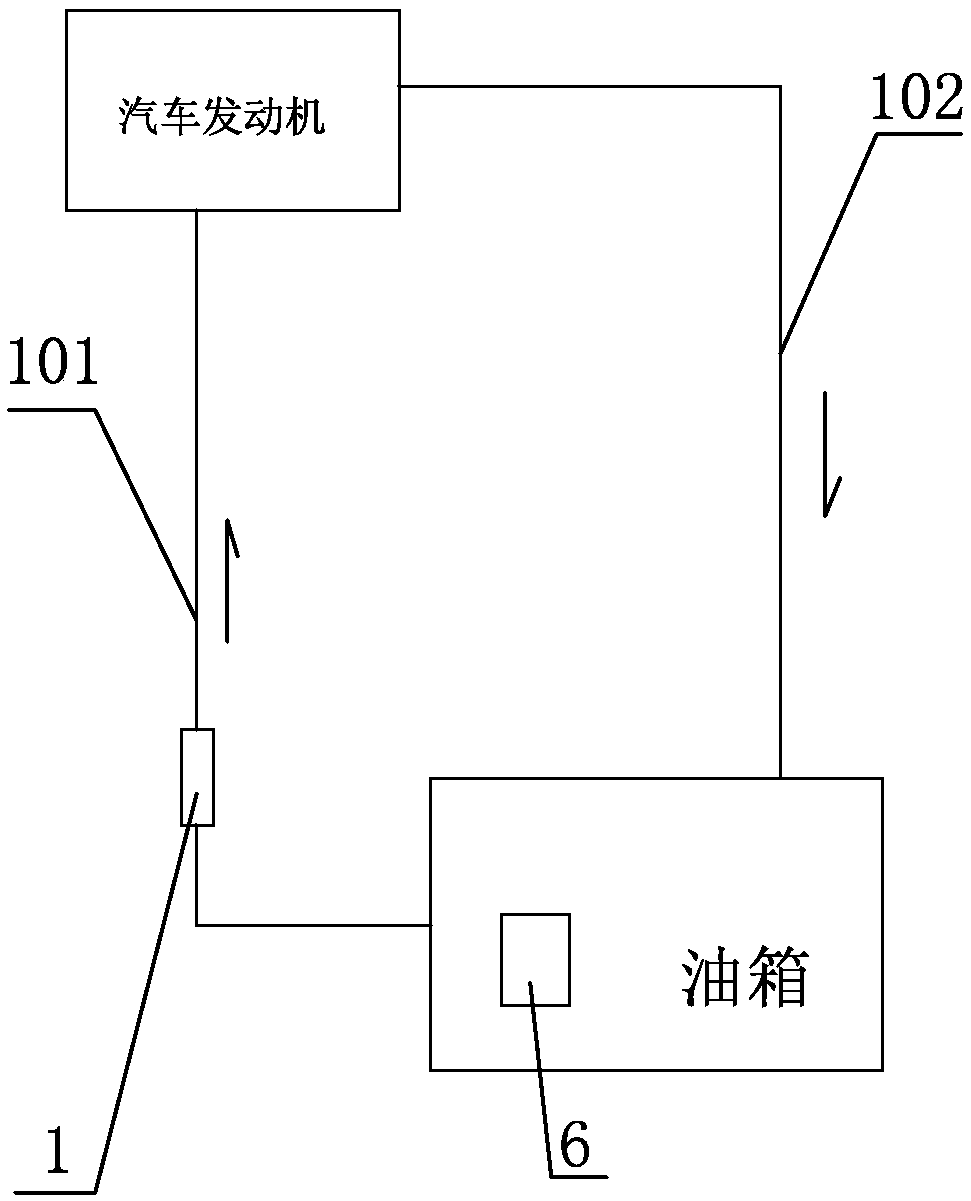

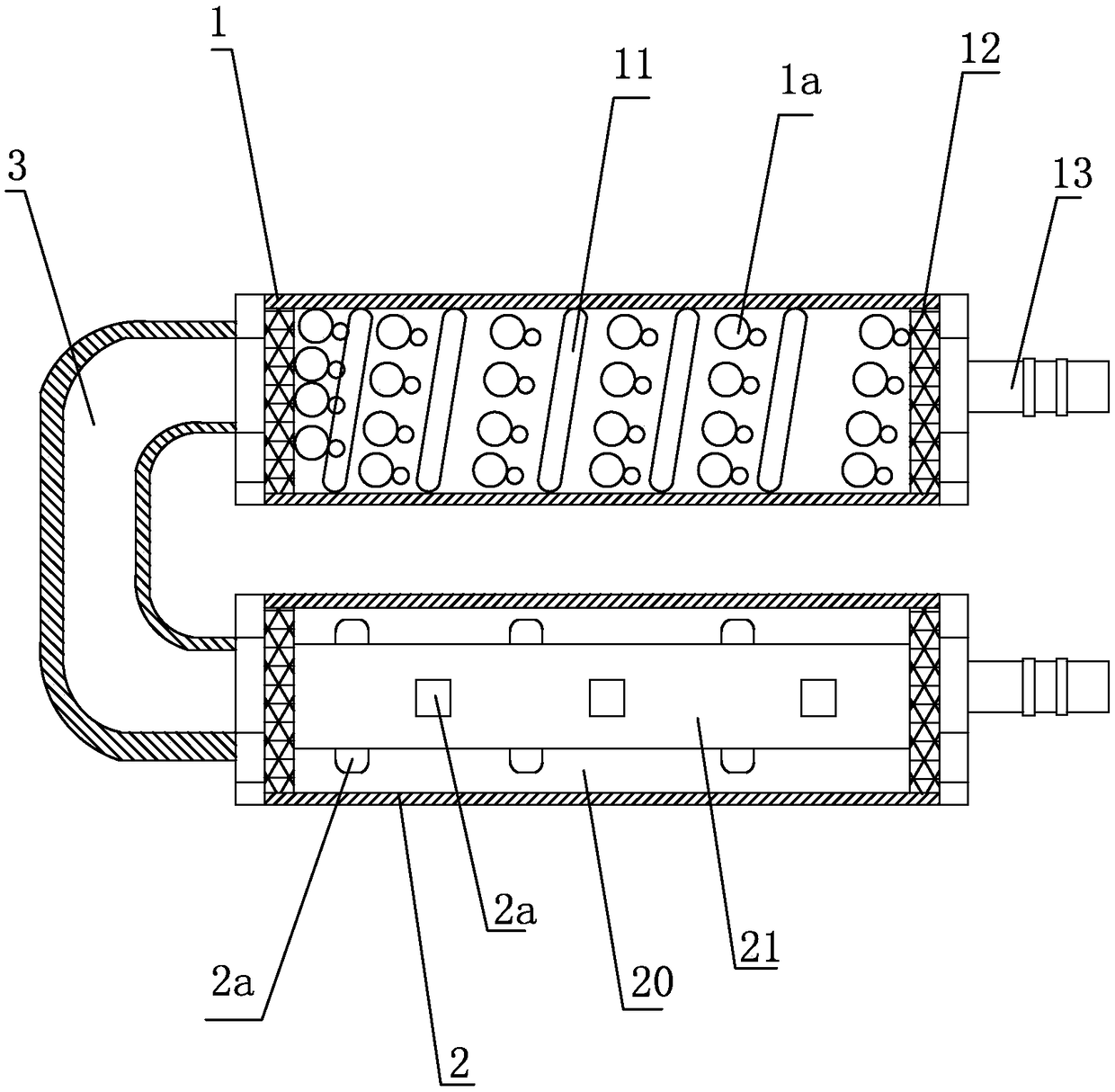

A high-efficiency fuel-saving device and its energy stone production process

A fuel saver and power stone technology, which is applied in machine/engine, combustion air/combustion-air treatment, liquid fuel feeder, etc., can solve the problems of not easy promotion, secondary pollution of combustion products, and large consumption. , to achieve the effect of reducing exhaust pollutant emissions, reducing living expenses and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Put 15g of far-infrared magnetite, 25g of tourmaline, 5g of medical stone, 25g of rare earth, and 30g of germanium into a mixer after mechanical crushing, and stir evenly, and spray mist water during the stirring process to obtain mixed raw materials. The pellets are pressed into balls by a press, and then the shape of the balls is screened, and finally the balls are rounded by a rounding ball plate, so that the degree of sphericity reaches more than 95%, and the balls are processed at a temperature of 50°C Drying treatment, and observe whether there are cracks in the ball. If there are cracks, it will be marked as unqualified products. If there are no cracks, it will be marked as qualified products. 350°C, then heated to 1000°C at a rate of 45°C / min and maintained for 45 minutes, then cooled to 400°C at a rate of 30°C / min, and cooled naturally to 20°C to complete the firing of the energy stone, and finally the energy stone Send it to the coating machine for rolling and...

Embodiment 2

[0056] Put 35g of far-infrared magnetite, 15g of tourmaline, 15g of medical stone, 15g of rare earth, and 20g of germanium into the mixer after mechanical crushing, and stir evenly, and spray mist water during the stirring process to obtain mixed raw materials. The pellets are pressed into balls by a press, and then the shape of the balls is screened, and finally the balls are rounded by a ball rounding disc, so that the degree of sphericity reaches more than 95%, and the balls are processed at a temperature of 70°C Drying treatment, and observe whether there are cracks in the ball. If there are cracks, it will be marked as unqualified products. If there are no cracks, it will be marked as qualified products. 450°C, then heated to 1300°C at a rate of 60°C / min and maintained for 60 minutes, then cooled to 500°C at a rate of 40°C / min, and cooled naturally to 25°C to complete the firing of the energy stone, and finally the energy stone Send it to the coating machine for rolling a...

Embodiment 3

[0058] Put 20g of far-infrared magnetite, 20g of tourmaline, 15g of medical stone, 20g of rare earth, and 25g of germanium into a mixer after mechanical crushing, and stir evenly, and spray mist water during the stirring process to obtain mixed raw materials. The pellets are pressed into balls by a press, and then the shape of the balls is screened, and finally the balls are rounded by a rounding ball plate, so that the degree of sphericity reaches more than 95%, and the balls are processed at a temperature of 60°C. Drying treatment, and observe whether there are cracks in the ball. If there are cracks, it will be marked as unqualified products. If there are no cracks, it will be marked as qualified products. 425°C, then heated to 1250°C at a rate of 50°C / min and maintained for 50 minutes, then cooled to 450°C at a rate of 35°C / min, and cooled naturally to 23°C to complete the firing of the energy stone, and finally the energy stone Send it to the coating machine for rolling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com