Well cementation rubber plug, well cementation method using same and staged fracturing device

A cementing rubber plug and cementing technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve problems such as scraping, overcome wear and fracture, reduce cementing construction risks, and improve The effect of cementing displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

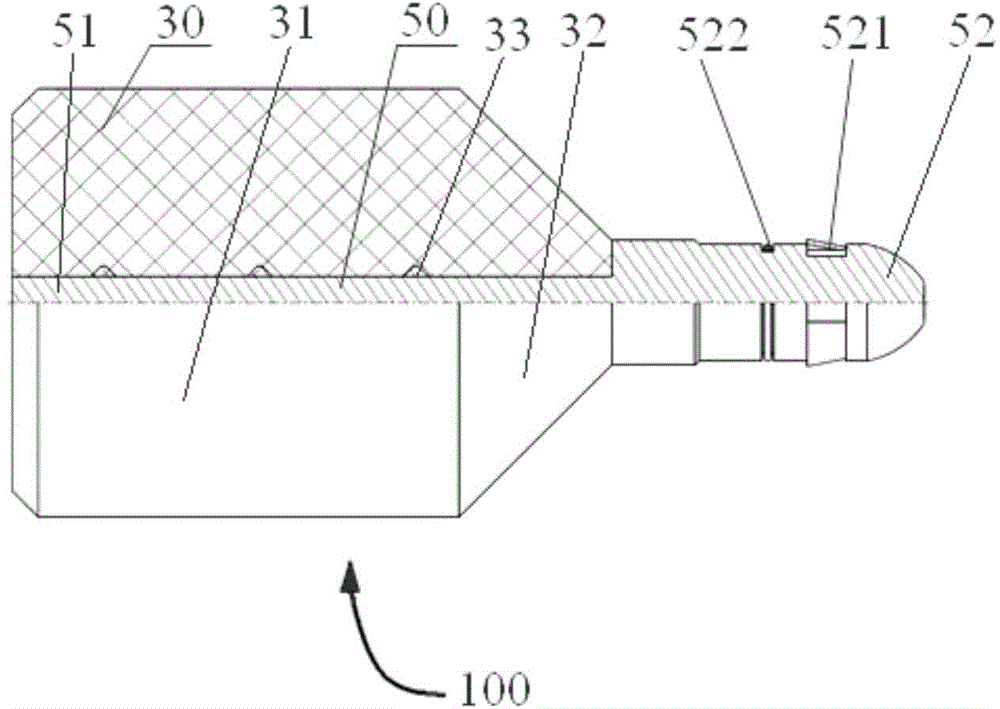

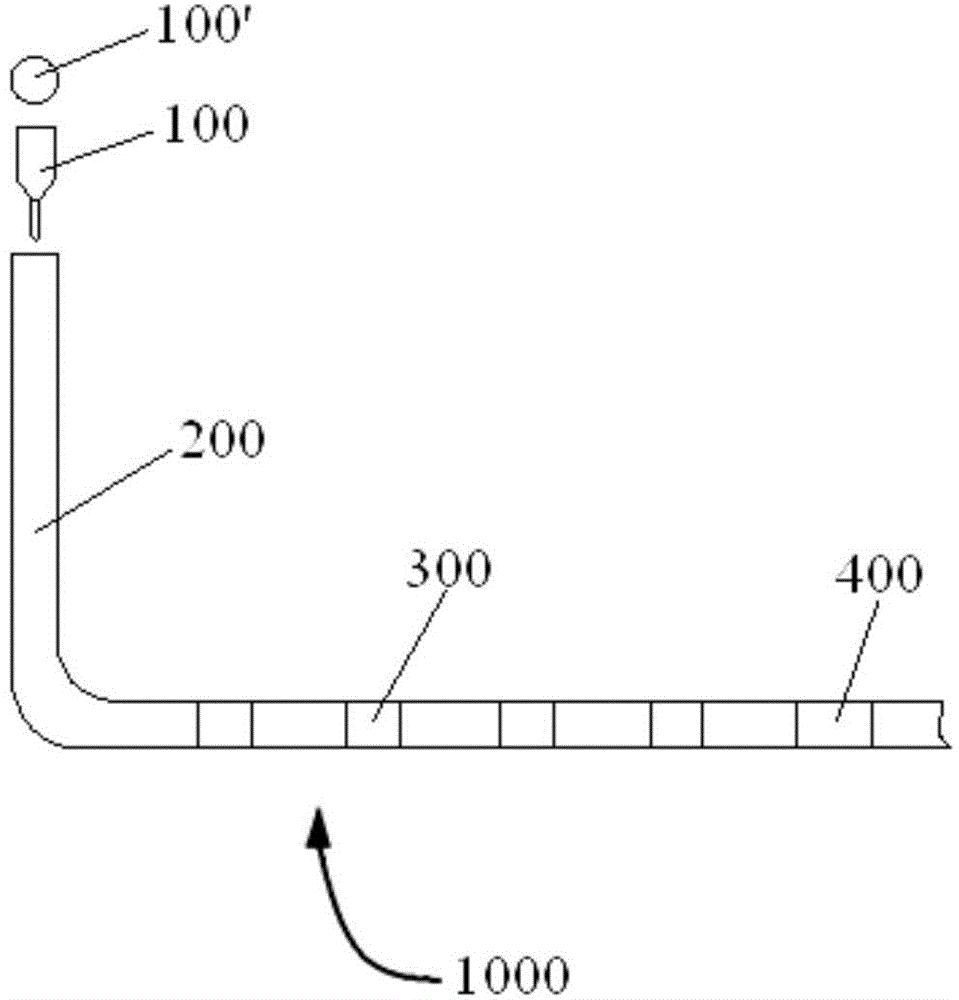

[0035] figure 1 A schematic structural diagram of the cementing plug 100 according to the first embodiment of the present invention is shown. like figure 1 As shown, the elastic body 30 of the cementing plug 100 is a cylindrical elastic body 31 . The cylindrical elastic body 31 is in complete contact with the inner wall of the pipe string, which facilitates the effective scraping of the inner wall of the pipe string.

[0036]According to the present invention, the core 50 includes a body 51 covered by the cylindrical elastic body 31 and a guide head 52 extending out of the cylindrical elastic body 31 . The body 51 in the core body 50 is used to support the cylindrical elastic body 30, and the guide head 52 is used to guide the cementing plug 100 when it travels in the inner wall of the pipe string. Under the action of the guide head, the cementing plug 100 It can smoothly pass through the inner wall of the pipe string with different inner diameters and smoothly reach the im...

Embodiment 2

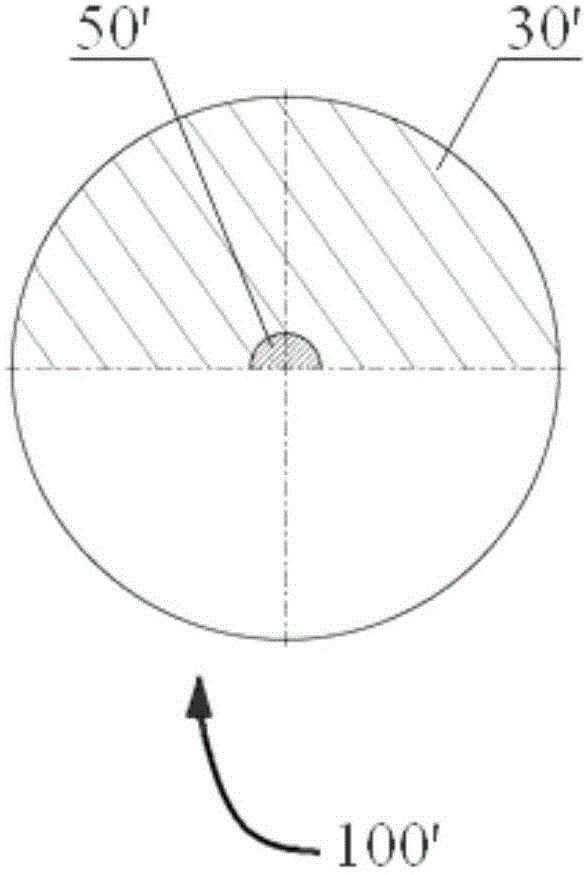

[0040] figure 2 A schematic structural diagram of the cementing plug 100' according to the second embodiment of the present invention is shown. like figure 2 As shown, the cementing plug 100' includes a spherical elastomer 30' and a spherical core 50'. When the cementing plug 100' with spherical elastomer is in use, the inner wall of the elastomer is always in close contact with and tangent to the inner wall of the pipe string, and the purpose of effectively scraping the inner wall of the pipe string can also be achieved. At the same time, the spherical cementing rubber plug 100' can also rotate while moving forward in the process of traveling under pressure, which is more conducive to effectively scraping the inner wall of the pipe string. In addition, the spherical cementing plug 100' is more flexible in use, and can smoothly pass through the inner wall of the pipe string with different inner diameters.

[0041] According to the present invention, the cementing plug is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com