AlP quantum dots and preparing method thereof

A technology of quantum dots and phosphorous source, applied in the field of AlP quantum dots and their preparation, can solve the problem that the preparation method of quantum dot products is not available, and achieve the effects of avoiding the interference of emission signals, simple operation and small size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

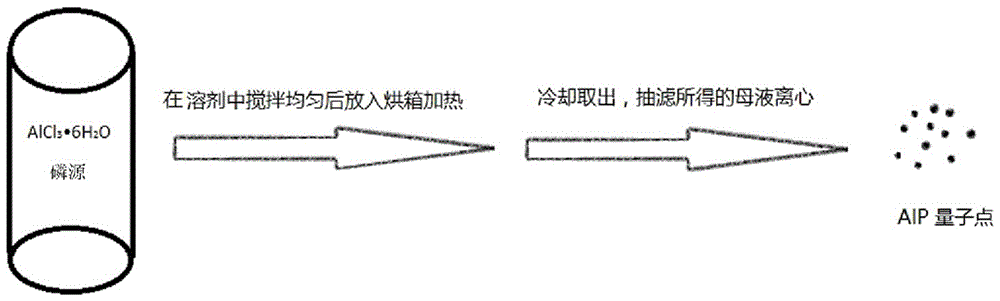

[0026] A preparation method of AlP quantum dots, figure 1 It is a schematic diagram of solvothermal synthesis of AlP quantum dots provided by the present invention. Specific steps are as follows:

[0027] (1) Weigh aluminum chloride hexahydrate, tri-o-methylphenylphosphine and HATU with a molar ratio of 1:0.5:0.5, respectively;

[0028] (2) Pour tri-o-methylphenylphosphine and HATU into the polytetrafluoroethylene liner, add an appropriate amount of toluene, put in a magnet and mix evenly on a magnet stirrer;

[0029] (3) After stirring for 20 minutes, add aluminum chloride hexahydrate, and after stirring for 10 minutes, take out the magnet, cover the inner lid, and put it into a stainless steel reaction kettle;

[0030] (4) Place the reaction kettle in a drying oven and heat it to 150° C. for 6 hours, stop heating, and cool it to room temperature naturally in the drying oven;

[0031] (5) Using a circulating water vacuum filter pump to separate the precipitate from the mot...

Embodiment 2

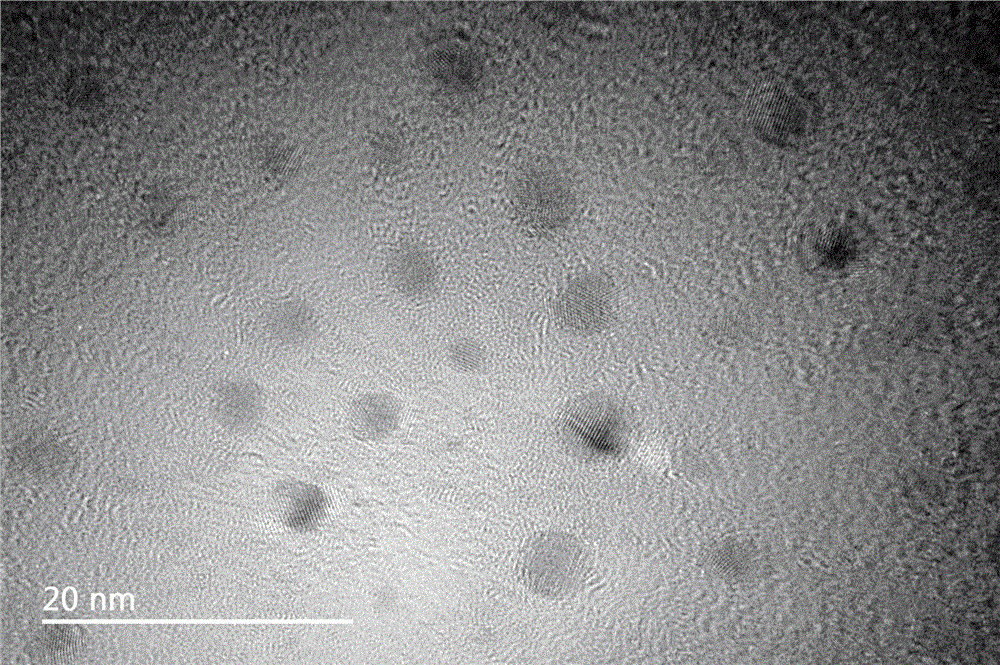

[0035] A preparation method of AlP quantum dots, the specific steps are the same as in Example 1, only the HATU in the raw material in step (1) is replaced by 1-butyl-3-methylimidazolium hexafluorophosphate [BMIM]PF 6 . The resulting quantum dot particles are uniformly dispersed, but the size distribution is slightly larger, with diameters ranging from 1 to 5 nm.

Embodiment 3

[0037] A preparation method of AlP quantum dots, the specific steps are the same as in Example 1, only the tri-o-methylphenylphosphine in the raw material of step (1) is replaced by PCl 5 . The resulting quantum dot particles are uniformly dispersed with a diameter of 1–4 nm. The nanoparticles gradually disappear under the strong electron beam of the high-power transmission electron microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com