Low-density coated ceramsite proppant and preparation method thereof

A low-density, proppant technology, applied in the field of petroleum proppant, can solve the problems of high oil fracturing support cost and ecological environment damage, and achieve the effects of improved crush resistance, low crush rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of low-density coated ceramsite proppant comprises the following steps:

[0030] The first step is to prepare the green body of ceramsite base material, grind the raw materials kaolin, ceramic soil, and coal ash, mix them evenly, put them into the granulator, atomize granulation in the granulator, and sieve to obtain the ceramsite base material green body;

[0031]The second step is to prepare the ceramsite base material, after drying the ceramsite base material green body obtained in the first step, calcining at 1000-1150°C for 8-9 hours, and passing through a 40 / 70 mesh sieve to obtain the ceramsite base material;

[0032] The third step is surface treatment, adding the ceramsite substrate obtained in the second step to the horizontal drum, the rotation speed of the horizontal drum is 60-120r / min, and the polishing time is 0.5-1.5 hours;

[0033] The fourth step is to heat the ceramsite substrate polished in the third step to 60-350°C, add mixe...

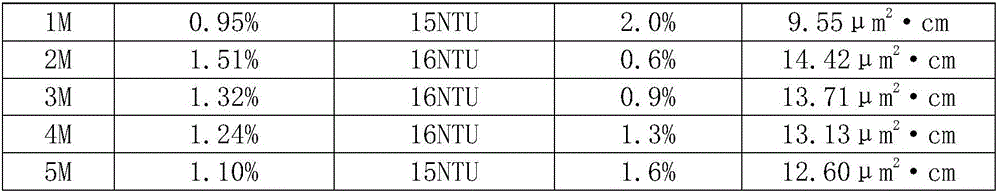

experiment example 1

[0042] Heat 100kg of ceramsite 40 / 70 mesh to 300°C, put it into the sand mixer, stir and cool down to 250°C, immediately add 1kg of epoxy resin and 1kg of phenolic resin into the sand mixer and stir evenly to form a mixture, then Add 0.2kg of phenalkamine and 0.2kg of hexamethylenetetramine and stir evenly. When the mixture starts to agglomerate, add 0.05kg of calcium stearate, and continue to stir evenly. After cooling, crushing and sieving, the obtained mixture becomes the film-coated proppant, numbered 1M.

experiment example 2

[0044] Heat 100kg of ceramsite 40 / 70 mesh to 80°C, put it into the sand mixer, stir it and cool it down to 60°C, immediately add 1kg of polyurethane resin and 1kg of silicone resin into the sand mixer and stir evenly to form a mixture, then Add 0.2kg of Lewis acid and 0.2kg of acid anhydride and stir well. Add 0.05 kg of zinc stearate when the mixture starts to agglomerate, and continue to stir evenly, and the obtained mixture is numbered 2M after being cooled, crushed and sieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com