A low-smoke, low-halogen, flame-retardant and cold-resistant cable material, preparation method and cable sheath

A cable material and cold-resistant technology, applied in the fields of low-smoke, low-halogen, flame-retardant and cold-resistant cable materials, preparation, and cable sheathing, can solve the problems of poor cold resistance of polyvinyl chloride plastics, low cold resistance, life-threatening, etc., and achieve good Effects of low-smoke and low-halogen performance, less hydrogen halide gas release, and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

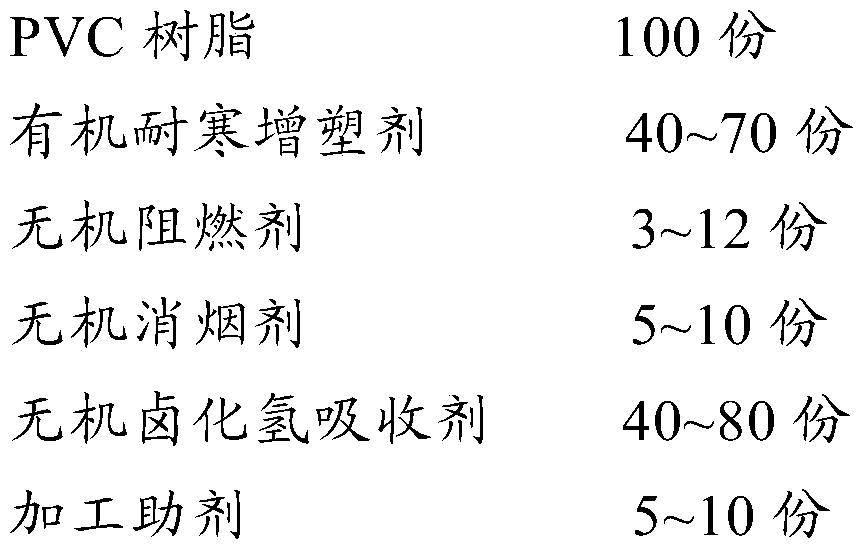

[0036] This embodiment provides a low-smoke, low-halogen, flame-retardant and cold-resistant cable material. The raw material formula includes the following weight components:

[0037]

[0038] Wherein, the processing aid is a blend of graft copolymer of acrylate and ethylene vinyl acetate and acrylonitrile-butadiene copolymer.

[0039] This embodiment provides the preparation method of the above-mentioned low-smoke, low-halogen, flame-retardant and cold-resistant cable material, including the following steps:

[0040] Weigh the components according to the above formula, then add them to the mixer for mixing, and discharge the mixture when the temperature reaches 115°C; then plasticize and granulate at 135°C to obtain low-smoke, low-halogen, flame-retardant and cold-resistant cable materials.

[0041] This embodiment provides a cable sheath, which is made of the above-mentioned low-smoke, low-halogen, flame-retardant and cold-resistant cable material.

[0042] The blend of...

Embodiment 2

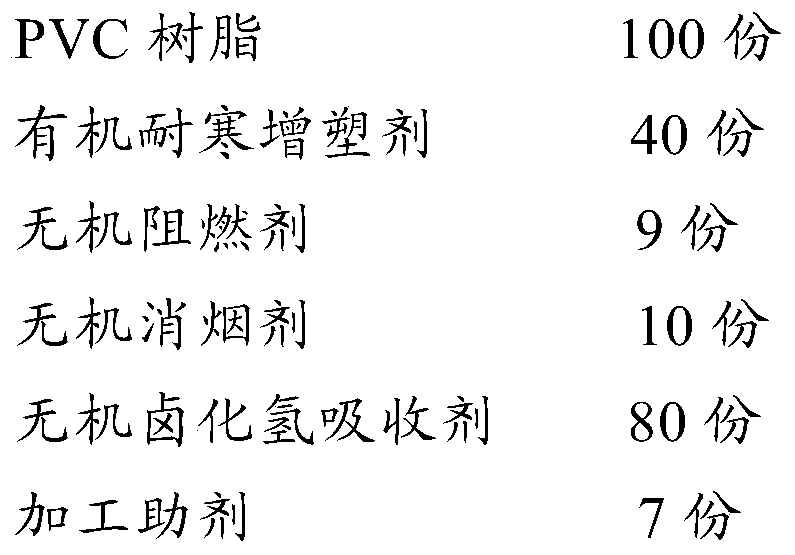

[0045] This embodiment provides a low-smoke, low-halogen, flame-retardant and cold-resistant cable material. The raw material formula includes the following weight components:

[0046]

[0047] Wherein, the processing aid is a blend of graft copolymer of acrylate and ethylene vinyl acetate and chlorinated polyethylene.

[0048] This embodiment provides the preparation method of the above-mentioned low-smoke, low-halogen, flame-retardant and cold-resistant cable material, including the following steps:

[0049] Weigh the components according to the above formula, then add them to the mixer for mixing, and discharge the mixture when the temperature reaches 112°C; then plasticize and granulate at 150°C to obtain low-smoke, low-halogen, flame-retardant and cold-resistant cable materials.

[0050] This embodiment provides a cable sheath, which is made of the above-mentioned low-smoke, low-halogen, flame-retardant and cold-resistant cable material.

Embodiment 3

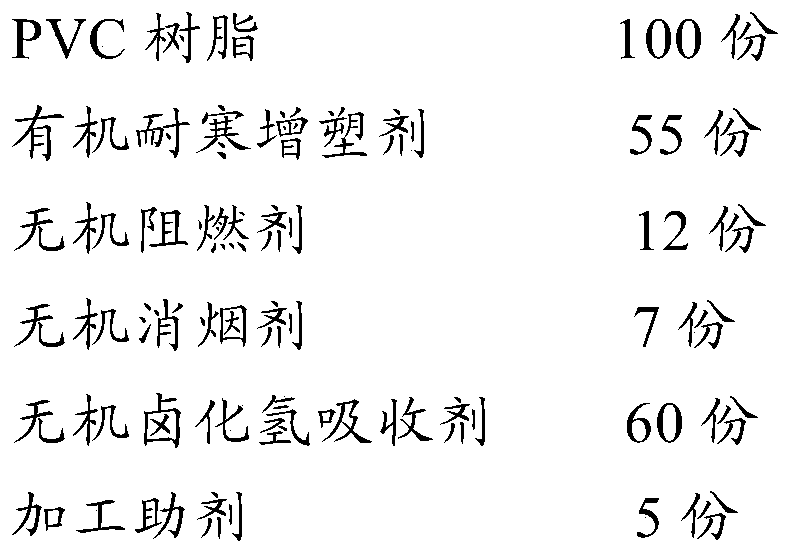

[0052] This embodiment provides a low-smoke, low-halogen, flame-retardant and cold-resistant cable material. The raw material formula includes the following weight components:

[0053]

[0054] Wherein, the processing aid is a blend of acrylate and ethylene vinyl acetate graft copolymer and acrylonitrile-butadiene copolymer, and acrylic ester and ethylene vinyl acetate graft copolymer and chlorinated polyethylene The blend, wherein, the weight ratio of the above two blends is 1:2.

[0055] This embodiment provides the preparation method of the above-mentioned low-smoke, low-halogen, flame-retardant and cold-resistant cable material, including the following steps:

[0056] Weigh the components according to the above formula, then add them to the mixer for mixing, and discharge the mixture when the temperature reaches 110°C; then plasticize and granulate at 115°C to obtain low-smoke, low-halogen, flame-retardant and cold-resistant cable materials.

[0057] This embodiment pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com