Polycarboxylate super plasticizer modified by utilizing straw and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of polycarboxylate water reducer and its preparation, can solve the problems that have not yet been seen in the test application effect, and achieve the goals of improving poor retarding effect, ensuring stability, and saving time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

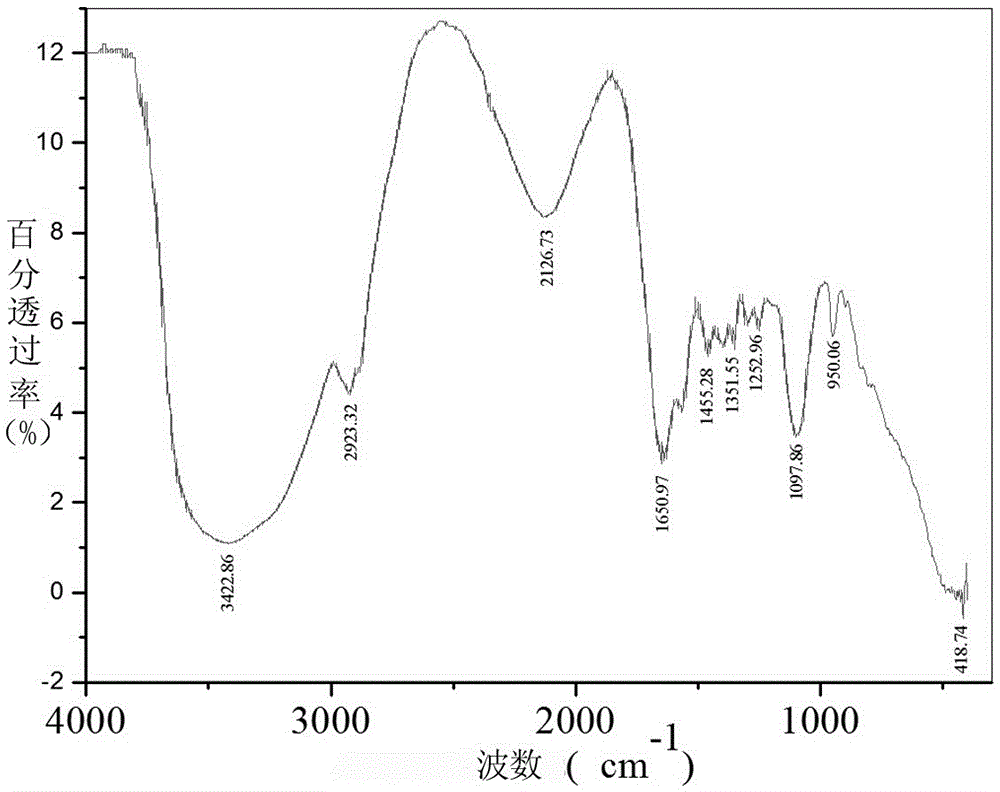

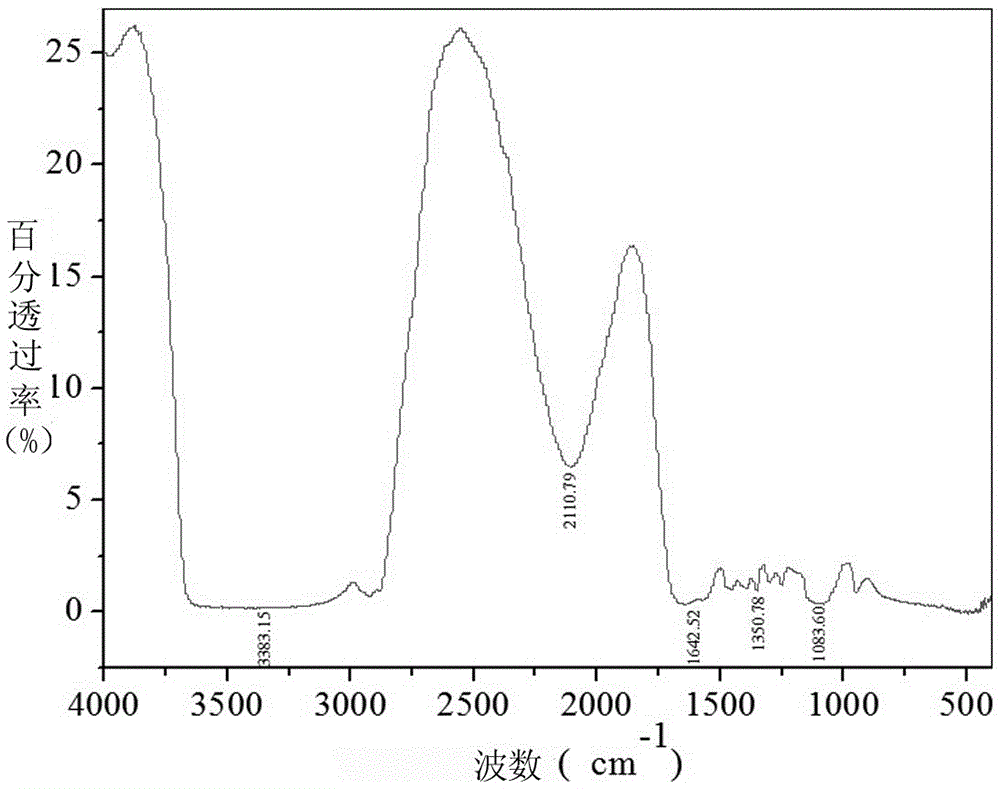

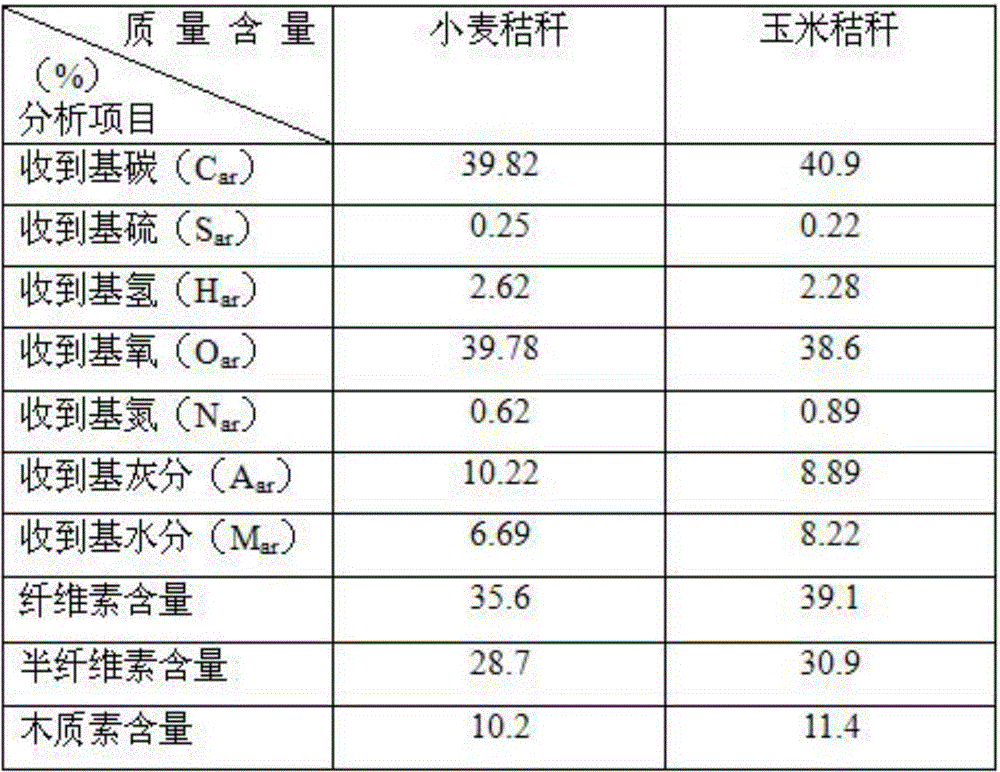

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a polycarboxylate water reducer modified by straw, the specific steps are as follows:

[0042] (1) Straw pretreatment: After crushing the straw, add dilute acid, stir and mix evenly, soak for 18-36 hours, filter and rinse the straw with clean water until it is neutral, and then set aside;

[0043] In terms of mass concentration, the dilute acid is 1-3% sulfuric acid or 3-5% hydrochloric acid;

[0044] Straw: solid-liquid ratio of dilute acid=1g:(8-12mL);

[0045] (2) Preparation of polycarboxylate water reducer modified by straw, the specific process is:

[0046] First, add methallyl polyoxyethylene-1000, methallyl polyoxyethylene-2400, maleic anhydride, acrylamide, sodium methacrylate and straw into a four-necked flask;

[0047] Second, add distilled water to ensure that the system concentration is 35-45%, and heat up to 70-90°C;

[0048] Third, install the upper reflux device and the constant pressure dropping funnel, add ammonium persulfate ...

Embodiment 2

[0060] A method for preparing a polycarboxylate water reducer modified by straw, the specific steps are as follows:

[0061] (1) Straw pretreatment: after crushing the straw, add dilute acid, stir and mix evenly, soak for 18 hours, filter and rinse the straw with clean water until it is neutral, and then set aside;

[0062] In terms of mass concentration, the dilute acid is 1% sulfuric acid;

[0063] Straw: the solid-to-liquid ratio of dilute acid=1g:8mL;

[0064] (2) Preparation of polycarboxylate water reducer modified by straw, the specific process is:

[0065] First, add methallyl polyoxyethylene-1000, methallyl polyoxyethylene-2400, maleic anhydride, acrylamide, sodium methacrylate and straw into a four-necked flask;

[0066] Second, add distilled water to ensure that the system concentration is 35%, and heat up to 70°C;

[0067] Third, install the upper reflux device and the constant pressure dropping funnel, add ammonium persulfate in the constant pressure dropping f...

Embodiment 3

[0075] A method for preparing a polycarboxylate water reducer modified by straw, the specific steps are as follows:

[0076] (1) Straw pretreatment: After crushing the straw, add dilute acid, stir and mix evenly, soak for 21 hours, filter and rinse the straw with clean water until it is neutral, and then set aside;

[0077] In terms of mass concentration, the dilute acid is 2% sulfuric acid;

[0078] Straw: the solid-liquid ratio of dilute acid=1g:9mL;

[0079] (2) Preparation of polycarboxylate water reducer modified by straw, the specific process is:

[0080] First, add methallyl polyoxyethylene-1000, methallyl polyoxyethylene-2400, maleic anhydride, acrylamide, sodium methacrylate and straw into a four-necked flask;

[0081] Second, add distilled water to ensure that the system concentration is 36%, and raise the temperature to 74°C;

[0082] Third, install the upper reflux device and the constant pressure dropping funnel, add ammonium persulfate in the constant pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com